The ADH Series Hydraulic Direct-Acting Brakes are high-performance, spring-applied, hydraulic-released safety brakes designed for demanding industrial applications. These fail-safe brakes provide reliable static holding and emergency stopping power, ensuring the safety and integrity of critical machinery. Their compact, direct-acting design offers a rapid response time and straightforward integration into new or existing systems.

Key Features and Technical Advantages

- Fail-Safe Operation: The brake is engaged by pre-set spring force, ensuring braking occurs automatically in the event of a power outage or hydraulic pressure loss. This is critical for safety-first applications.

- Direct-Acting Mechanism: With no intermediate levers, the hydraulic pressure acts directly on the piston, providing fast response times for both engagement and release.

- Superior Thermal Stability: The open disc design allows for efficient heat dissipation, maintaining consistent braking performance even during frequent cycling, unlike enclosed drum brakes.

- Consistent Braking Torque: The braking force is linearly related to the spring force and is unaffected by the direction of rotation, delivering predictable and stable performance.

- Simplified Maintenance: The design allows for easy inspection and replacement of friction pads, minimizing downtime and maintenance costs. The small, built-in air gap (0.05–0.15mm) requires minimal adjustment over the life of the pads.

- Compact and Robust Construction: Delivers high braking torque in a smaller and lighter package compared to traditional drum brakes, saving valuable space and reducing structural load.

ADH Series Model Specifications

Select the appropriate model based on your required braking force, disc diameter, and system pressure. The braking force for each model can be precisely determined using the provided formulas.

Braking Force Calculation Guide

The braking force formula is Braking Force (N) = (P – 0.25) x Constant, where:

- P is the working pressure of your hydraulic system in MPa.

- 0.25 MPa is the equivalent back pressure from the return springs.

- The Constant is specific to each model (e.g., 1560 for ADH60).

The Braking Torque (N.m) is then calculated by: Braking Force (N) / 1000 x Effective Friction Radius (B).

| Model | Applicable Disc Diameter (ΦA mm) | Effective Friction Radius (B mm) | Working Pressure (P MPa) | Braking Force Formula (N) | Cylinder Volume (cm³) | Weight (kg) |

|---|---|---|---|---|---|---|

| ADH60 | 315 – 445 | 117 – 183 | 5 | (P – 0.25) x 1560 | 26 | 23 |

| ADH90 | 495 – 625 | 190 – 255 | 5 | (P – 0.25) x 3000 | 35 | 46 |

| ADH120 | 705 – 795 | 278 – 322 | 5 | (P – 0.25) x 4710 | 54.9 | 68 |

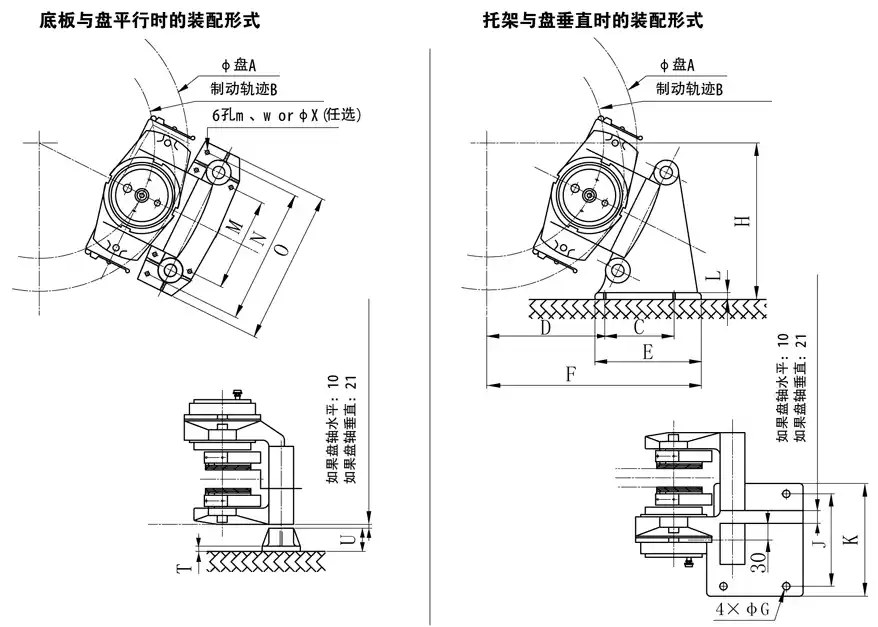

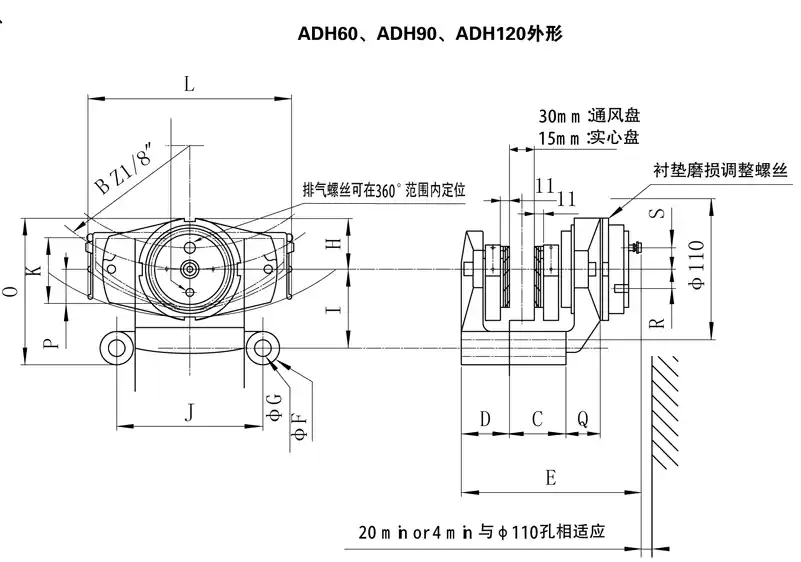

Dimensional Drawings and Installation Data

The following drawing and table provide all necessary dimensions for system design and integration. Please ensure proper alignment of the brake caliper with the brake disc during installation.

| Model | A | B | C | D | E | F | G | H | J | K | L | M | N | O | P | R | S | T | U | W | X |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ADH60 | 315-445 | 117-183 | 90-115 | 135-160 | 130-155 | 245-295 | 12 | 160-225 | 110 | 140 | 10 | 120 | 210 | 240 | 54 | 80 | 72 | 10 | 65 | 8 | 9 |

| ADH90 | 495-625 | 190-255 | 145-170 | 165-190 | 195-220 | 335-385 | 14 | 250-315 | 120 | 150 | 15 | 160 | 270 | 300 | 66 | 96 | 80 | 12 | 70 | 10 | 11 |

| ADH120 | 705-795 | 278-322 | 210-230 | 230-250 | 270-290 | 470-510 | 16 | 355-400 | 140 | 175 | 20 | 200 | 370 | 400 | 70 | 100 | 103 | 15 | 85 | 12 | 13 |

Recommended Applications

The robust design and reliable performance of the ADH Series make it an ideal choice for:

- Cranes and Hoisting Equipment (e.g., Gantry Cranes, Overhead Cranes)

- Winches and Winders

- Port and Deck Machinery

- Conveyor Belt Systems

- Mining and Metallurgical Machinery

- Wind Turbine Yaw and Rotor Brakes

Operating Conditions

- Ambient Temperature: -25°C to +40°C

- Operating Frequency: Less than 720 cycles per hour

- Altitude: Not exceeding 2000m

- Environment: Suitable for indoor use or outdoor use with rain/snow protection. The environment must be free from explosive media and corrosive gases or conductive dust that could damage metal and insulation.

- Relative Humidity: Not exceeding 90%

- Power Supply: DC110V or DC220V. Please specify any special voltage requirements during ordering.