In a cement plant, dust is not just a housekeeping issue; it’s a relentless, abrasive force that actively seeks to destroy your most critical machinery. Among its many victims, industrial braking systems are often the first to fall, leading to costly downtime, frequent parts replacement, and significant safety risks.

This guide will expose the three primary ways cement dust acts as a “silent killer” to your brakes and, more importantly, detail the definitive engineering solution to protect your operations.

The Three-Pronged Attack of Cement Dust

Abrasive clinker and cement dust doesn’t just cause one problem; it launches a coordinated assault on your braking systems.

1. The Sandpaper Effect: Accelerated Abrasive Wear

This is the most obvious form of attack. Cement and clinker dust are highly abrasive. When this gritty powder gets between a brake pad and a disc, or a brake shoe and a drum, it acts like sandpaper. It dramatically accelerates the wear of friction materials and can even score and damage the metal surfaces of the drum or disc, leading to:

- Rapid loss of braking torque

- Frequent, costly replacement of friction linings

- The need for premature re-machining or replacement of drums/discs

2. The Concrete Effect: Clogging and Seizing

When cement dust mixes with ambient moisture or lubricant grease, it can form a hard, concrete-like substance. This buildup clogs critical moving parts within the brake mechanism, such as:

- Pivot pins

- Self-adjusting mechanisms

- Linkages and levers

The result? The brake may fail to engage properly, or worse, fail to release, causing it to drag. A dragging brake generates immense heat, leading to brake fade, warped components, and even fire risk.

3. The Contamination Effect: Infiltration of Actuators

The finest dust particles can work their way past inadequate seals on brake actuators, like electro-hydraulic thrusters. Once inside, this dust contaminates the hydraulic fluid, turning it into a grinding slurry that destroys internal seals, pistons, and impellers. This leads to sluggish brake response, loss of release force, and eventual failure of the actuator itself.

The Solution: A Fortress, Not a Fence

You cannot stop the dust, so you must choose a brake designed to live in it. The solution is not more frequent cleaning; it’s a superior design philosophy: the fully enclosed industrial drum brake system.

Why the Enclosed Drum Brake is King in Cement Plants

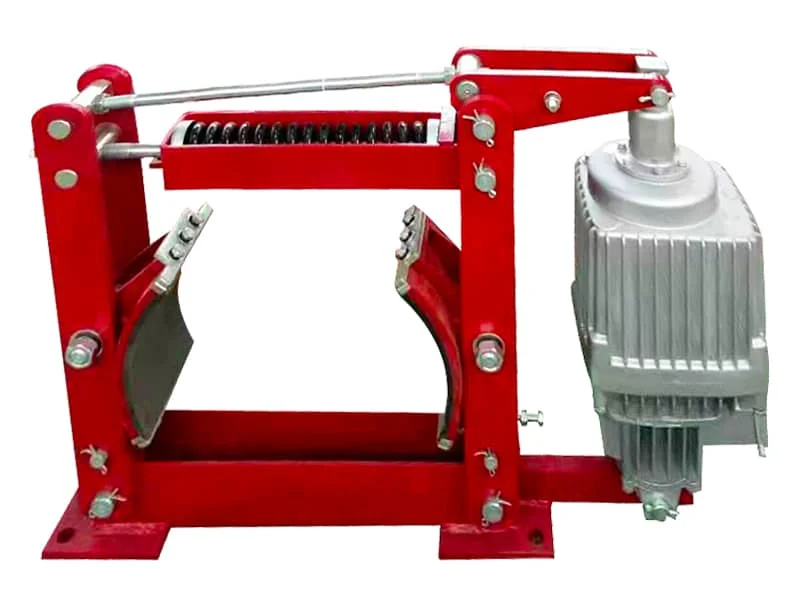

Unlike an open-style disc brake where the pads and rotor are completely exposed, a heavy-duty drum brake acts as a fortress.

- Primary Protection: The robust brake drum itself serves as the first and most effective barrier, completely shielding the internal brake shoes and actuation mechanism from the vast majority of airborne dust.

- Reduced Wear: By keeping the abrasive dust off the primary friction surfaces, the life of the brake shoes is dramatically extended.

- Reliable Actuation: With the internal linkages protected from clogging, the brake engages and disengages reliably every time.

It’s a System: Don’t Forget the Actuator Seals

A sealed drum is only half the battle. The actuator that powers the brake must be equally protected. This is why pairing a robust drum brake with a high-quality, well-sealed electro-hydraulic thruster is critical. Look for thrusters with features like:

- Dual-lip rod seals

- Bellows or protective shrouds for the piston rod

- IP65 or higher ingress protection ratings

This ensures the entire braking system is fortified against dust.

The Right Brake for the Job

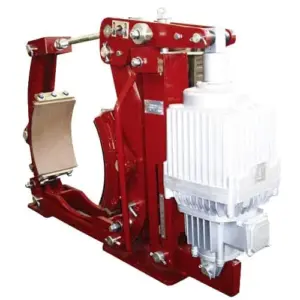

For the most demanding applications in a cement plant, from long belt conveyors and bucket elevators to rotary kilns and crushers, a heavy-duty electro-hydraulic drum brake is the clear engineering choice.

Our YWZ Series Electro-Hydraulic Drum Brakes are specifically designed for these harsh environments. Their robust, enclosed construction and pairing with our sealed Ed Series Electro-Hydraulic Thrusters provide the reliability and longevity that cement plant operations demand.

Conclusion: Design Against Dust, Don’t Just Clean It

Fighting a losing battle with dust-related brake failures is a drain on your maintenance budget and a threat to your production targets. Instead of treating the symptoms, it’s time to cure the disease.

By implementing a braking solution designed from the ground up to operate in high-dust environments, you can drastically reduce maintenance, increase uptime, and improve the overall safety of your plant.