On any construction site, from a skyscraper reaching for the clouds to a sprawling infrastructure project, the movement of materials is constant. Cranes, hoists, and winches are the muscles of the operation, lifting tons of steel, concrete, and equipment. But what ensures these powerful machines operate with precision and, most importantly, safety? The answer lies in their braking systems. A robust brake isn’t just a component; it’s the foundation of site safety and operational efficiency.

This comprehensive guide is designed for project managers, equipment superintendents, and safety engineers. We will cover everything you need to know about construction and hoisting brakes—from the types of brakes used on different mechanisms to selection criteria and critical maintenance practices.

Why Brakes are the Most Critical Safety System in Construction Hoisting

In an environment filled with hazards, control is everything. A brake failure on a construction site can lead to catastrophic consequences. Here’s why they are non-negotiable:

- Personnel Safety: The primary function is to prevent uncontrolled load drops, which is the leading cause of crane-related fatalities.

- Equipment Protection: Precise braking prevents shock loads and damage to the crane’s structure, motor, and gearbox.

- Regulatory Compliance: Standards from bodies like OSHA (Occupational Safety and Health Administration) and ASME (American Society of Mechanical Engineers) mandate specific requirements for braking systems, including redundancy and fail-safe designs.

Braking Systems Across Key Construction Equipment

Different hoisting equipment has unique operational demands, requiring tailored braking solutions.

Tower Cranes

The skyline-defining giants require multiple brakes for their three-dimensional movements. Their primary hoist brake system is always a fail-safe design, typically an electro-hydraulic drum or disc brake, often with a secondary brake for redundancy on critical lifts.

Crawler & Mobile Cranes

These versatile machines use powerful brakes on their hoist winches. Due to their mobility and exposure to varied conditions, their braking systems must be robust, reliable, and easy to service in the field.

Construction Hoists (Personnel & Material Lifts)

For elevators that scale the side of a building, safety is paramount. They use a primary hoist motor brake (often an electromagnetic fail-safe brake) coupled with an entirely separate, overspeed-activated safety device that grips the guide rail—a classic example of multi-layered safety.

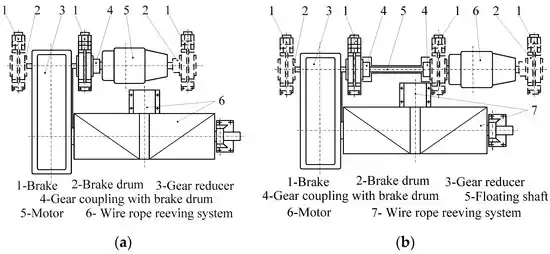

Anatomy of a Crane: Braking Needs by Mechanism

- Hoisting (Lifting): This is the most critical. It requires a fail-safe brake capable of holding 125% to 200% of the motor’s rated load torque (as per standards). The brake must engage automatically upon power loss.

- Slewing (Swinging): This requires a brake that can provide smooth deceleration to prevent load swing and hold the boom steady against wind forces.

- Trolleying/Luffing (Moving the hook/boom): These mechanisms also need brakes to provide accurate load positioning and hold the trolley or boom in place.

- Traveling (Moving the entire crane): For rail-mounted cranes, travel brakes and storm brakes are essential for controlled movement and secure parking.

Top Brake Technologies for the Construction Industry

Three types of brakes dominate the construction and hoisting landscape due to their reliability and power.

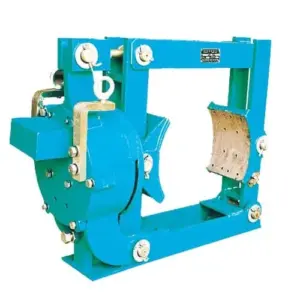

1. Electro-Hydraulic Drum Brakes

The industry workhorse. Proven, robust, and easy to maintain, brakes like our YWZ Series are the go-to choice for hoisting and traveling mechanisms on countless cranes. They offer high torque and a natural fail-safe design.

2. Electro-Hydraulic Disc Brakes

Offering superior heat dissipation and more consistent performance, disc brakes like the YPZ2 Series are increasingly used for high-speed, high-frequency hoisting applications where performance is critical.

3. Electromagnetic Brakes

These compact, fast-acting brakes are often integrated directly into the hoist motor. The SE Series is a perfect example, commonly used as a primary motor brake on smaller hoists and winches.

Selection Checklist: Choosing the Right Construction Hoist Brake

Use this checklist when specifying or replacing a brake for your equipment:

- Daily Visual Check: Look for hydraulic leaks, loose bolts, and audible signs of dragging.

- Weekly Check: Measure brake pad/lining thickness. Check the air gap between the pad and disc/drum. Verify the functionality of the manual release.

- Use OEM Parts: Always replace worn components with genuine OEM spare parts. A non-spec friction material can drastically alter braking performance and violate safety certifications.

Your Partner in Construction Site Safety

Choosing the right braking system is a critical decision that impacts every aspect of your construction project. It requires a deep understanding of the application, the technology, and the uncompromising demands of safety.

We are specialists in high-performance braking systems for the construction and hoisting industry. Our engineering team can help you select, implement, and maintain the perfect braking solution to keep your site safe, compliant, and productive.

- ✅ Braking Torque: Does it meet the required safety factor (e.g., 1.5x motor torque)?

- ✅ Fail-Safe Design: Is it spring-applied, power-released?

- ✅ Duty Cycle: Can it handle the required number of stops per hour without overheating?

- ✅ Environmental Resistance: Is it sealed against dust, moisture, and corrosion? (IP rating)

- ✅ Manual Release: Does it have a feature for manual release during maintenance or rescue operations?

- ✅ Serviceability: Are wear parts like brake pads and linings easily accessible for inspection and replacement?