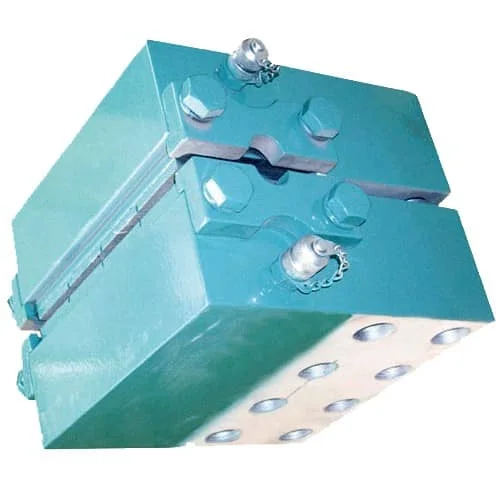

DADH Series Hydraulic Direct-Acting Brake: Braking Solutions for Heavy-Duty Industrial Applications

In heavy-duty industrial applications, the performance of the braking system directly affects the safety and efficiency of equipment operation. The DADH series of hydraulic direct-acting brakes are designed to provide reliable braking functionality to meet the challenges of high-intensity, continuous industrial environments, satisfying the stringent requirements of applications in terms of braking force, response speed, and durability.

Precise braking capability: Meets demanding load requirements

The DADH series brakes use precise hydraulic control to ensure stable braking force output under different working conditions.

- DADH195 Type: This model is suitable for applications involving high inertia and heavy loads. At a working pressure of 100 bar, the DADH195 achieves a static braking force of 195,000 N (with A-type pads) and a dynamic braking force of 145,500 N (with M-type pads). The braking torque can be calculated using the following formula: Braking torque = [Braking force / 1000] × [(ΦB) / 2 – 90] N·m. This design facilitates precise quantification of the relationship between braking force and disc diameter, providing a controllable torque for equipment braking.

- DADH103 Model: This model is suitable for medium to locally heavy-duty applications, characterized by its compact structure and balanced performance. At a working pressure of 120 bar, the DADH103 can generate a static braking force of 103,000 N (with A-type pads) and a dynamic braking force of 77,250 N (with M-type pads). The braking torque can be calculated as **=[braking force/1000] x [(ΦB)/2-50] N.m; under specific configurations, the braking force can be derived from a pressure of 675 N/bar, with the braking torque calculation formula being **=[braking force/1000] x (ΦB/2-83) N.m**. The availability of different pad options (A or M) and braking torque coefficients allows users to select appropriate braking characteristics based on actual operating conditions.

Optimize response time and operational efficiency

The rapid response of the braking system is crucial to improving the operating cycle of industrial equipment. The DADH series is designed to optimize response speed and reduce operating losses.

- The DADH series hydraulic system optimizes the displacement capacity of the piston. The full release displacement capacity of the DADH195 is 57 cm³ (14.25 cm³ per piston), while that of the DADH103 is 22.7 cm³ (5.5 cm³ per piston). These parameters reflect the piston return efficiency, which helps reduce the waiting time after brake release.

- All DADH models feature a precise 3 mm single-sided clearance (such as the DADH195-DZ II), ensuring that the friction pads and brake discs separate quickly after braking is released, thereby effectively reducing friction drag and the resulting heat loss, and improving the overall operating efficiency of the system.

- The DADH series brakes support high operating frequencies and can handle braking cycles of less than 720 times per hour, making them suitable for industrial applications that require frequent start-stop operations.

Structural strength and environmental adaptability

The DADH series brakes demonstrate excellent structural strength and environmental adaptability in harsh industrial environments, aiming to extend service life and reduce maintenance requirements.

- Operating temperature range: This series of products can operate stably in an environment with temperatures ranging from -25°C to 40°C.

- Altitude suitability: Designed for use at altitudes not exceeding 2000m.

- Environmental Medium Protection: The product structure is capable of protecting against non-corrosive gases and non-conductive dust, and can be used in indoor environments or environments with rain and snow protection measures where the relative humidity does not exceed 90%. These characteristics help reduce the impact of external environmental factors on the performance and service life of the brake.

- In terms of product weight, the DADH195 weighs 230 kg and the DADH103 weighs 60 kg. These weight specifications are commensurate with their load-bearing capacity and structural robustness.

- Under wear conditions, the total volume of DADH195 can reach 1726 cm³ (431.5 cm³ per piston), while the total volume of DADH103 can reach 91 cm³ (22.7 cm³ per piston). This parameter indicates that even with a certain degree of wear on the friction pads, the brake can still maintain the effective operation of the hydraulic system, helping to extend the maintenance cycle.

- The brake supports DC 110V or DC 220V power supply voltages and can be configured according to specific user requirements.

The DADH series of hydraulic direct-acting brakes are designed to provide stable and efficient braking functions for industrial equipment, with parameters and design features that provide technical support for reliable equipment operation.