Why DCPZ Electromagnetic Disc Brakes Are a Smart Choice for Precision Braking in Industrial Equipment

In industrial equipment, the braking system is not a supporting role, but a key component that determines the stability, safety and even product quality of the whole machine. Especially in scenarios such as winding systems, transmission control, and tension adjustment, the performance of the brake directly affects the efficiency and stability of the production line.

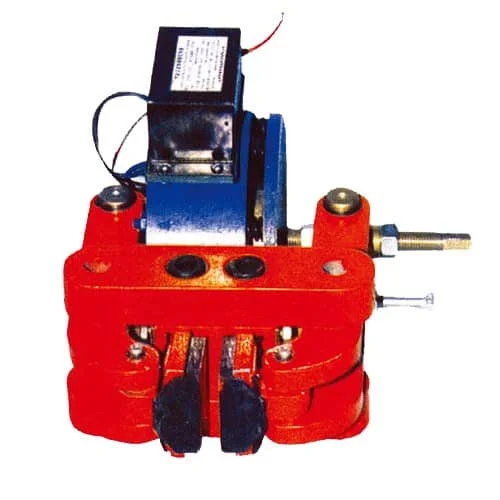

The DCPZ series of electromagnetic disc brakes are designed to meet these high-demand applications. It is suitable for medium and low torque transmission occasions. It is not only used for traditional deceleration and parking brakes, but also particularly suitable for systems that are sensitive to tension control such as papermaking, steel unwinding, and cable reeling.

✅ Key advantages of DCPZ

🧩 Lighter, does not mean sacrificing performance

A major advantage of DCPZ is its compact structure and light weight. For equipment manufacturers, this means lower installation loads and more flexible space layout-especially in automated production lines with high requirements for equipment compactness. This is particularly important.

⚙️ Diverse material matching to adapt to different working conditions

Depending on the use environment of different industries (such as high-frequency starting/braking, humid dust environment, and continuous operation at room temperature), DCPZ provides a variety of friction plate material options, including low-wear type, high-temperature resistant type, and dry/wet compatible materials to help engineers achieve the best friction coefficient-life balance point.

🔒 Safety design concept: power off is brake

Adopting the “normally closed” design, DCPZ automatically brakes when the power is off, and adopts a spring-loaded + electromagnetic release structure to ensure that there is no risk of sliding or inertial collision even if power is off or equipment is abnormal.

🛠️ Reserved manual release function

Some factory equipment may have sudden power outages or urgent manual intervention. DCPZ has designed a manual release mechanism to facilitate technicians to manually release the brake when the power is off, ensuring the flexibility and safety of debugging and maintenance work.

🌱 Environmentally friendly materials, easy maintenance

The brake pads are made of asbestos-free environmentally friendly materials, which not only meet the environmental protection standards of modern manufacturing, but also facilitate users to operate easily when replacing, without complicated disassembly and assembly.

🧪 Typical application environment and parameter matching suggestions

- DCPZ brakes are suitable for the following environmental conditions:

- Temperature range: -25°C to +40°C

- Altitude: ≤ 2000 meters

- Installation environment: Indoors, avoid flammable, corrosive gases or conductive dust

- Standard voltage: AC 380V / 50Hz, special voltage levels can be customized

It is recommended to use tension sensors or inverter control logic in tension control systems to achieve more sophisticated braking adjustment capabilities, especially suitable for constant tension control of long linear materials.

🔚 DCPZ, not just a “brake”

DCPZ is not just a “stop” solution, it is a multi-dimensional response to braking stability, precision control, and safety assurance. As the braking system becomes more intelligent and customized, DCPZ has become a reliable standard option for engineers and equipment manufacturers with its mature and stable structure and flexible adaptability.

If you are looking for an industrial brake that can handle changing environments and balance performance and safety, DCPZ is worth including in your selection list.