Choosing the right braking system is one of the most critical decisions in industrial machinery design and operation. It directly impacts safety, productivity, and long-term operational costs. While both disc and drum brakes have been industry workhorses for decades, they possess fundamentally different characteristics that make them suitable for very different applications.

This comprehensive guide will break down the key differences between industrial disc and drum brakes, moving beyond simple theory to provide practical insights that help you make the right choice for your cranes, conveyors, winches, and other heavy-duty equipment.

The Fundamentals: How They Work

To understand their differences, we first need to understand their core mechanics.

How Industrial Disc Brakes Work

A disc brake system consists of a brake disc (or rotor) that rotates with the wheel or shaft, and a caliper that holds brake pads. When actuated (hydraulically, pneumatically, or electromagnetically), the caliper clamps the brake pads onto the disc, creating friction that slows or stops the rotation. It’s an “open” system, with the key components exposed to the air.

How Industrial Drum Brakes Work

A drum brake is an “enclosed” system. It features a brake drum that rotates with the wheel, and inside it, a set of brake shoes. When actuated, a mechanism (like our Ed Series Electro-Hydraulic Thruster) pushes the shoes outward against the inner surface of the drum, creating friction to stop the motion.

Head-to-Head Comparison: 5 Key Factors for Industry

Let’s compare these two systems across the metrics that matter most in industrial settings.

1. Braking Torque & Power

Drum Brakes often have a “self-energizing” or “servo” effect. The rotation of the drum can pull one of the shoes in tighter, multiplying the braking force. This allows them to generate extremely high static braking torque within a compact, enclosed design, making them excellent for holding heavy loads.

Disc Brakes generally do not have this self-energizing effect. Their braking force is directly proportional to the clamping force applied by the caliper. While a single caliper may provide less torque than a comparable drum brake, disc brake systems can easily be scaled by using larger discs or multiple calipers on a single disc for immense stopping power.

2. Heat Dissipation: The Critical Difference

This is arguably the most significant performance differentiator.

Disc Brakes, with their open design, expose the rotor directly to the surrounding air. This allows for superior and rapid heat dissipation. In high-cycle, high-energy stopping applications (like the main hoist on a busy crane), this prevents “brake fade”—a dangerous condition where overheating causes a loss of friction and braking power.

Drum Brakes, being enclosed, trap heat inside the drum. While suitable for applications with long cooling periods, they can be prone to overheating and fading during frequent, repetitive use.

3. Maintenance & Inspection

Disc Brakes are champions of easy maintenance. The brake pads and disc surface are typically visible without disassembly. Pad wear can be inspected visually, and pad replacement is a relatively quick and straightforward task.

Drum Brakes require the removal of the drum to inspect or service the internal shoes and hardware. This process is more labor-intensive and time-consuming, leading to longer periods of equipment downtime.

4. Performance in Harsh Environments

Drum Brakes’ enclosed design offers a significant advantage here. It protects the braking surfaces from dust, debris, water, and corrosive elements common in environments like mines, steel mills, and cement plants. This protection ensures more consistent braking performance in dirty conditions.

Disc Brakes’ open design can be a liability in extremely dusty or gritty environments, as abrasive particles can become trapped between the pad and disc, accelerating wear. However, for marine or high-humidity applications, their open design prevents water from being trapped, which can be an issue inside a brake drum.

5. Cost: Initial Investment vs. Total Cost of Ownership (TCO)

Historically, Drum Brakes have had a lower initial purchase price for a given torque rating, thanks to their self-energizing effect and simpler manufacturing.

However, when considering the Total Cost of Ownership (TCO), Disc Brakes often pull ahead. Their significantly lower maintenance time, reduced downtime for service, and longer life in high-cycle applications can lead to substantial long-term savings.

Quick Comparison Chart

| Feature | Industrial Disc Brakes | Industrial Drum Brakes |

|---|---|---|

| Braking Torque | Good to Excellent (Scalable) | Excellent (Self-Energizing) |

| Heat Dissipation | Excellent | Fair to Poor |

| Maintenance | Easy & Fast | Labor-Intensive |

| Harsh Environments | Good (Moisture), Vulnerable (Dust) | Excellent (Dust/Debris) |

| Brake Fade | High Resistance | Prone under heavy use |

| TCO | Often Lower | Often Higher |

Making the Right Choice: Application-Specific Scenarios

So, which brake is right for you?

When to Choose Industrial Disc Brakes

Choose a disc brake system, like our YPZ2 Series Electro-Hydraulic Disc Brakes, when your application involves:

- High-Energy Stopping: Main hoists for cranes, downhill conveyors, and wind turbines where large kinetic energy must be converted to heat.

- High-Cycle Frequency: Applications requiring frequent stops where heat buildup is the primary concern.

- Precision & Control: Systems where smooth, modulated braking is needed.

- Low Maintenance Requirements: When minimizing equipment downtime for service is a top priority.

When to Choose Industrial Drum Brakes

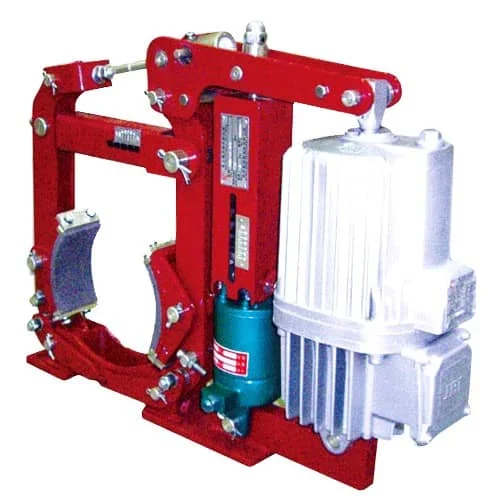

Choose a drum brake system, like our robust YWZ4 Series Electro-Hydraulic Drum Brakes, when your application involves:

- Static Holding: Parking brakes on crane travel mechanisms, conveyor holdbacks, and movable bridges where high static torque is needed.

- Extremely Dusty/Dirty Environments: Mining, cement production, or steel mills where the braking mechanism needs protection.

- Cost-Sensitive Projects: When the initial capital expenditure is the primary deciding factor and the duty cycle is not severe.

Conclusion: A Partner in Performance

The “disc vs. drum” debate doesn’t have a single winner. The best choice is entirely dependent on your specific application’s demands for performance, safety, and operational efficiency. By understanding these core differences, you can select a braking system that not only works, but excels.

If you’re still unsure which path to take, our team of experts is here to help. We can analyze your application’s unique challenges and recommend a braking solution that delivers uncompromising safety and value.