Model Code Explanation

According to the structure diagram provided:

DZ – Brake Wheel Diameter (mm) – Mounting Code – Special Requirements (Text Description)

Example:

DZ–400–A–FC

→ Brake wheel diameter: 400 mm

→ Mounting form: Type A

→ Special requirement: FC (Anti-corrosion)

Technical parameters and dimensions

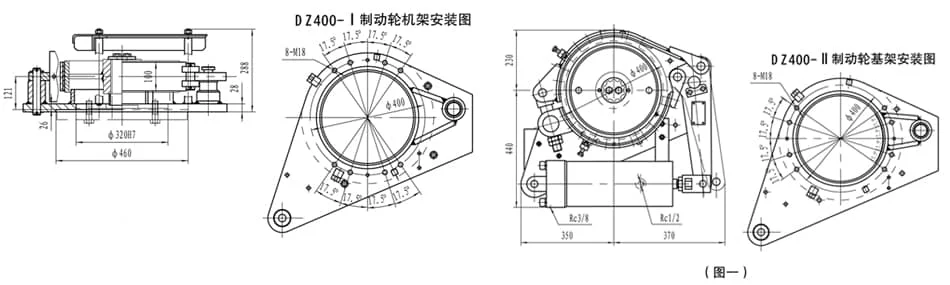

Parameters of DZ400-I & DZ400- II

| Model | Braking torque(Nm) | Oil pressure(MPa) | Working stroke (mm) | Setback distance (mm) | Weight(Kg) | |

| Brakes | Matching hydraulic cylinder | |||||

| DZ400-I | HC215C | 6815 | 2.45 | 50 | 3 | 217 |

| DZ400- II | ||||||

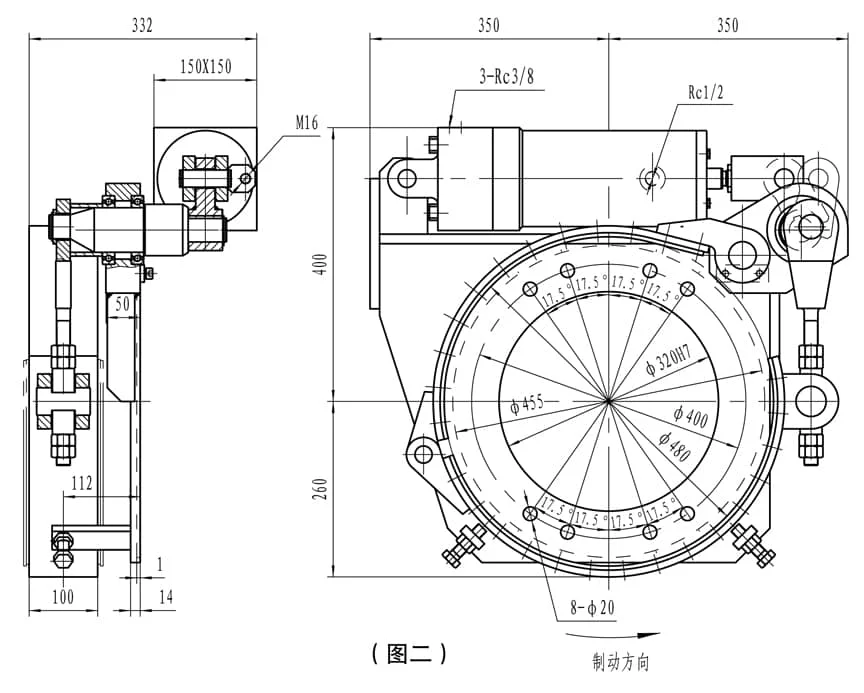

Parameters of DZ480-I

| Type | Rated torque(N.m) | Oil pressure(Mpa) | Working stroke(mm) | Retreat from(mm) | Weight(kg) | |

| Brake | Matching Hydraulic cylinder | |||||

| DZ480-I | HC305A | 9280 | 18.2 | 50 | 1.5 | 120 |

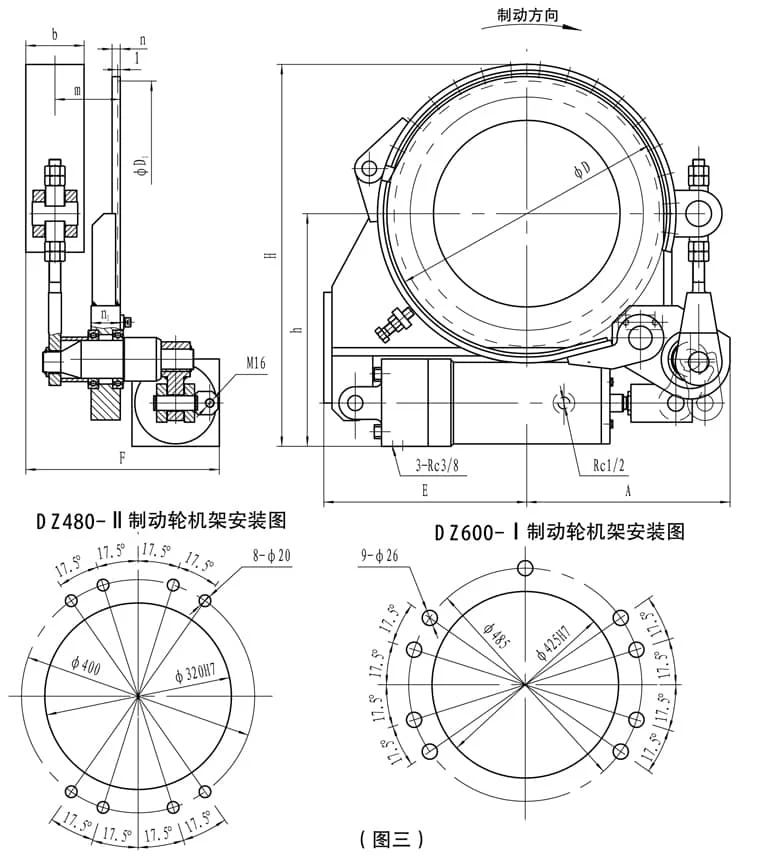

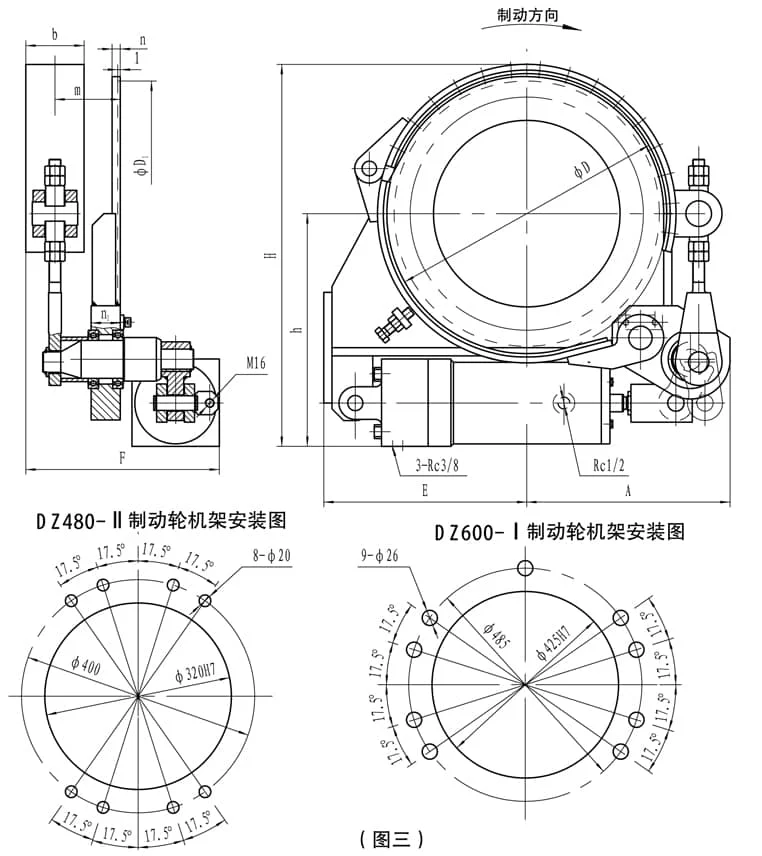

Parameters of DZ480-Ⅱ& DZ600-I

| Type | Rated torque(N.m) | Oil pressure(Mpa) | Working stroke(mm) | Retreat from(mm) | |

| Brake | Matching Hydraulic cylinder | ||||

| DZ480-Ⅱ | HC305A | 9280 | 18.2 | 50 | 1.5 |

| DZ600-I | HC205A | 14700 | 18.2 | 50 | 1.5 |

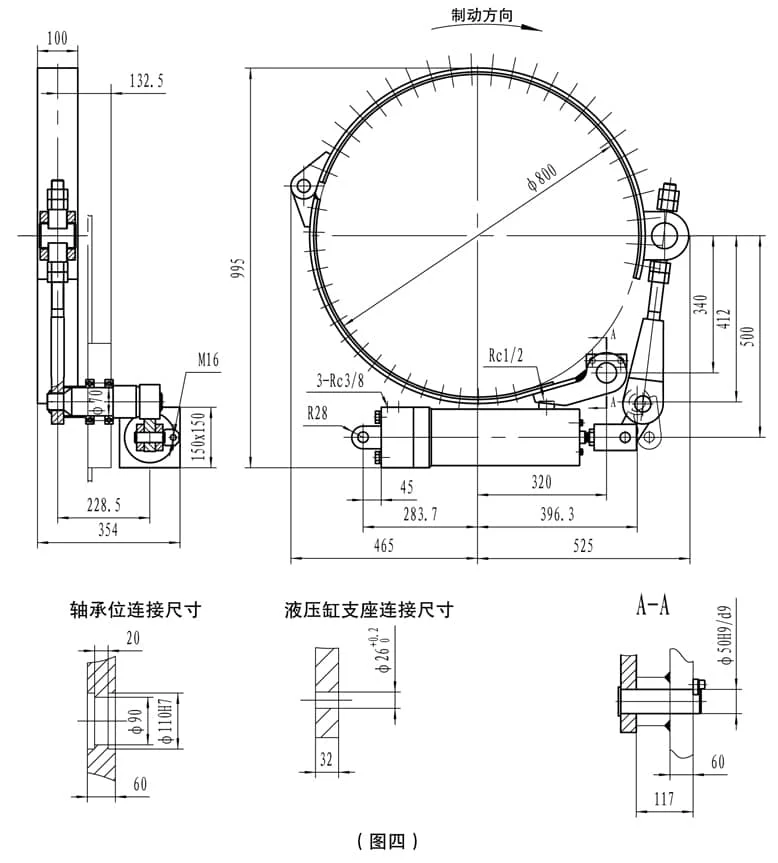

Parameters of DZ800-I

| Type | Rated torque(N.m) | Oil pressure(Mpa) | Working stroke(mm) | Retreat from(mm) | Weight(kg) | |

| Brake | Matching Hydraulic cylinder | |||||

| DZ800-I | HC205C | 22065 | 18.2 | 60 | 1.5 | 124 |

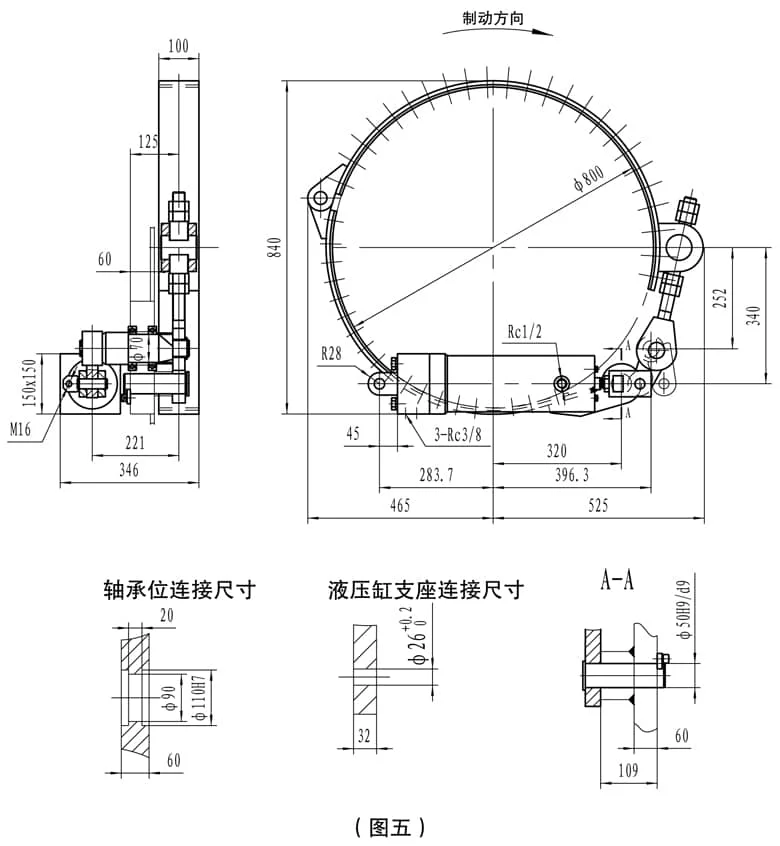

Parameters of DZ800-II

| Type | Rated torque(N.m) | Oil pressure(Mpa) | Working stroke(mm) | Retreat from(mm) | Weight(kg) | |

| Brake | Matching Hydraulic cylinder | |||||

| DZ800-II | HC205A | 22065 | 18.2 | 60 | 1.5 | 124 |

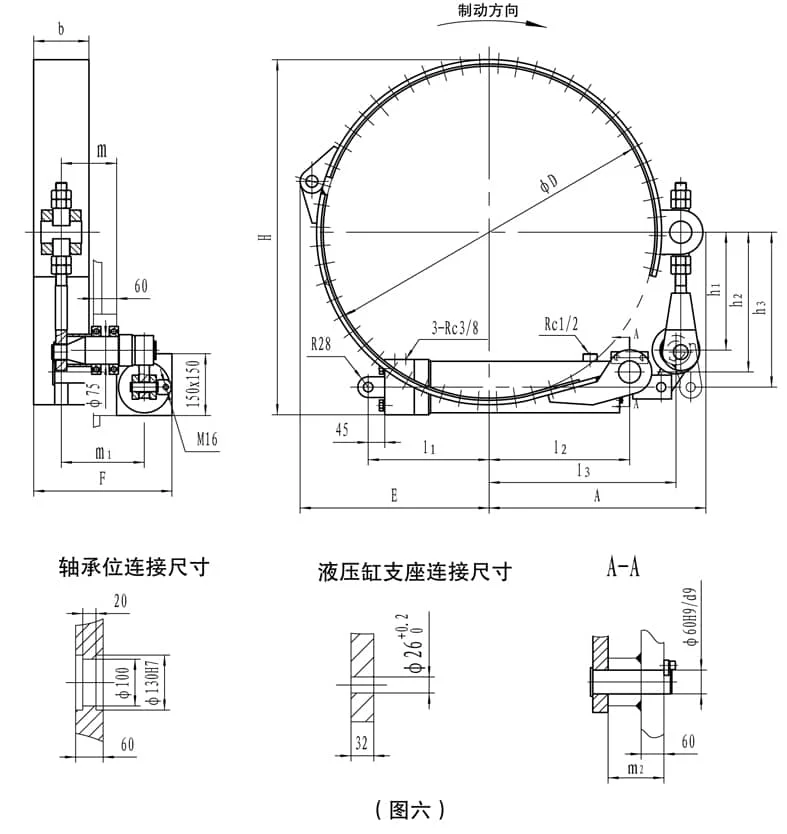

Parameters of DZ900-I & DZ900-II

| Type | Rated torque(N.m) | Oil pressure(Mpa) | Working stroke(mm) | Retreat from(mm) | |

| Brake | Matching Hydraulic cylinder | ||||

| DZ900-I | HC205C | 29420 | 18.2 | 60 | 1.5 |

| DZ900-II | HC630C | 46300 | 18.2 | 60 | 1.5 |

Overview

The DZ Series Band Brake is specifically engineered for marine cranes, providing reliable braking for slewing, hoisting, and luffing mechanisms. Designed for demanding offshore environments, this brake series ensures operational safety and consistent performance, making it an ideal solution for maritime lifting equipment.

Key Advantages

- Safe and Stable Operation Spring-applied and hydraulically released, the DZ Series delivers smooth and reliable braking even under high-frequency operation. Perfect for applications requiring frequent start-stop cycles.

- Compact and Lightweight Design

With a simple yet robust structure, the brake is lightweight and easy to install. Key pivot points feature self-lubricating bearings, eliminating the need for regular greasing and minimizing maintenance efforts. - Environmentally Friendly Materials

Asbestos-free brake linings are used to ensure compliance with environmental and health safety standards. A green, responsible choice for modern industrial applications. - High Efficiency and Long Service Life

Designed for high transmission efficiency and durability, the DZ Series maintains strong performance even under harsh working conditions. High-wear components are built to last, reducing downtime and replacement costs. - Corrosion-Resistant for Marine Environments

Anti-corrosion models are available for use in environments exposed to rain, snow, salt spray, or corrosive gases. Operates reliably across a wide temperature range from -20°C to 40°C.