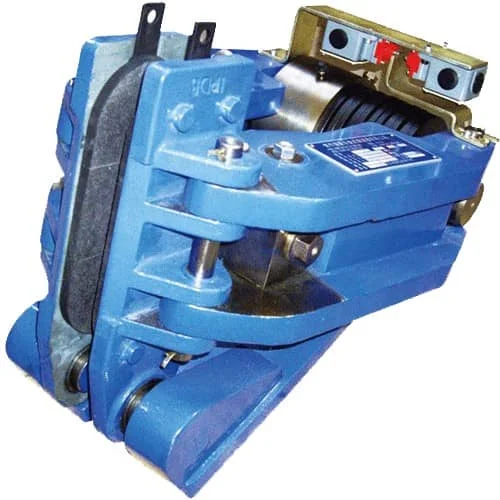

En el sector industrial, la seguridad y la fiabilidad son fundamentales para mantener la eficacia operativa y la protección del personal. Los frenos de disco hidráulicos a prueba de fallos de la serie SH ofrecen un rendimiento preciso respaldado por unas especificaciones técnicas detalladas, lo que los hace esenciales para aplicaciones de alta exigencia.

Estos frenos presentan un diseño compacto con diámetros de rotor que van desde los 190 mm en modelos como el 5SH hasta los 600 mm en variantes más grandes como el ST40SH. Las capacidades de par correspondientes varían de 165 Nm a 2880 Nm. Por ejemplo, el modelo ST25SH-C puede generar una fuerza de frenado máxima de 180.000 N (180 kN). El par de frenado se calcula a partir de la fórmula:

N.m = (Fuerza de frenado (N) / 1000) × (ΦB/2 - 60 ó 75)

where ΦB is the brake disc diameter. This precise calculation ensures the brake’s torque output aligns with specific equipment requirements.

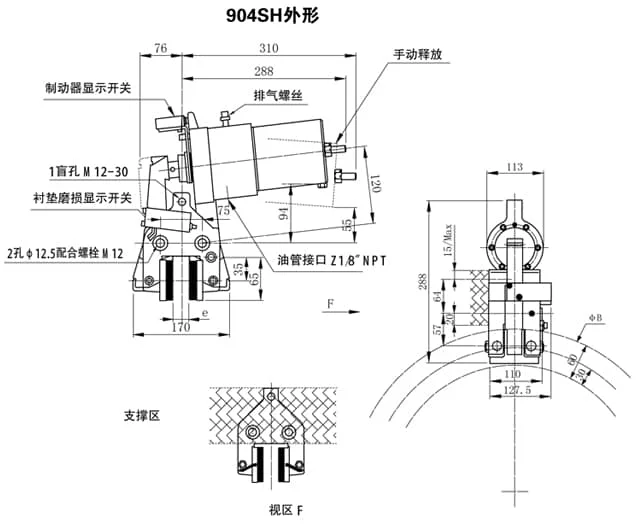

El tiempo de respuesta de todos los modelos es de cero segundos, lo que garantiza una activación inmediata en situaciones de parada de emergencia. Por ejemplo, el modelo 904SH tiene una respuesta instantánea con un volumen de desplazamiento totalmente liberado de 33 cm³ y una cilindrada de 98 cm³, lo que permite una rápida transmisión de la presión del fluido y minimiza el retardo de frenado, algo crucial para la seguridad en grúas, maquinaria minera y equipos de manipulación portuaria.

Las fuerzas de frenado máximas difieren entre modelos: la ST16SH ofrece hasta 150 kN, mientras que la ST10SH proporciona unos 81 kN, lo que permite soluciones a medida para diversas demandas de carga. Los volúmenes de los cilindros oscilan entre 275 ml (ST10SH) y 810 ml (ST40SH), lo que garantiza una aplicación de presión y una estabilidad de frenado constantes.

La precisión de la instalación se mantiene con una excentricidad máxima de la cara del disco de ±0,2 mm y una desviación de la perpendicularidad no superior a ±4‰. Las fijaciones de alta resistencia, como los pernos M36 de grado 12.9 con un par de apriete de hasta 4.280 Nm, garantizan un montaje seguro bajo cargas pesadas.

La resistencia medioambiental también es una característica clave. Para entornos exteriores o corrosivos, algunos modelos están disponibles con revestimientos resistentes a la corrosión, adecuados para su uso en condiciones duras como alta humedad, niebla salina o exposición a gases agresivos. Por ejemplo, el modelo ST25SH-A soporta presiones de disparo de hasta 190 bares, con un volumen de desplazamiento totalmente liberado de 95 ml, lo que garantiza un rendimiento constante incluso en condiciones climáticas extremas.

Los mecanismos automáticos de compensación del desgaste, como la detección de líneas de desgaste en las pastillas de fricción, mantienen estable el par de frenado a lo largo de la vida útil del componente, reduciendo la frecuencia de mantenimiento. El indicador de desgaste del modelo 450SH permite la supervisión en tiempo real para evitar fallos en los frenos debidos a un desgaste excesivo de las pastillas.

En resumen, los frenos de disco hidráulicos a prueba de fallos de la serie SH combinan un control preciso del par, una respuesta rápida, una construcción duradera y resistencia medioambiental. Estas características responden a las principales necesidades de los clientes en cuanto a seguridad, fiabilidad y facilidad de mantenimiento en aplicaciones industriales exigentes, proporcionando una solución de frenado fiable para maquinaria crítica en toda una gama de sectores de alto riesgo.