Operating in industries like mining, oil & gas, chemical processing, or agriculture means confronting a constant, invisible threat: the risk of an explosive atmosphere. In these environments, a single spark from standard industrial equipment can lead to catastrophic consequences. This is why specialized, explosion-proof equipment isn’t just a recommendation; it’s a legal and ethical necessity.

Industrial braking systems are no exception. But navigating the world of explosion-proof standards like ATEX and IECEx can be daunting. What do all the codes and markings mean? And how does a brake system actually achieve this level of safety?

This guide will demystify these standards and empower you to select the right, compliant braking system for your hazardous application.

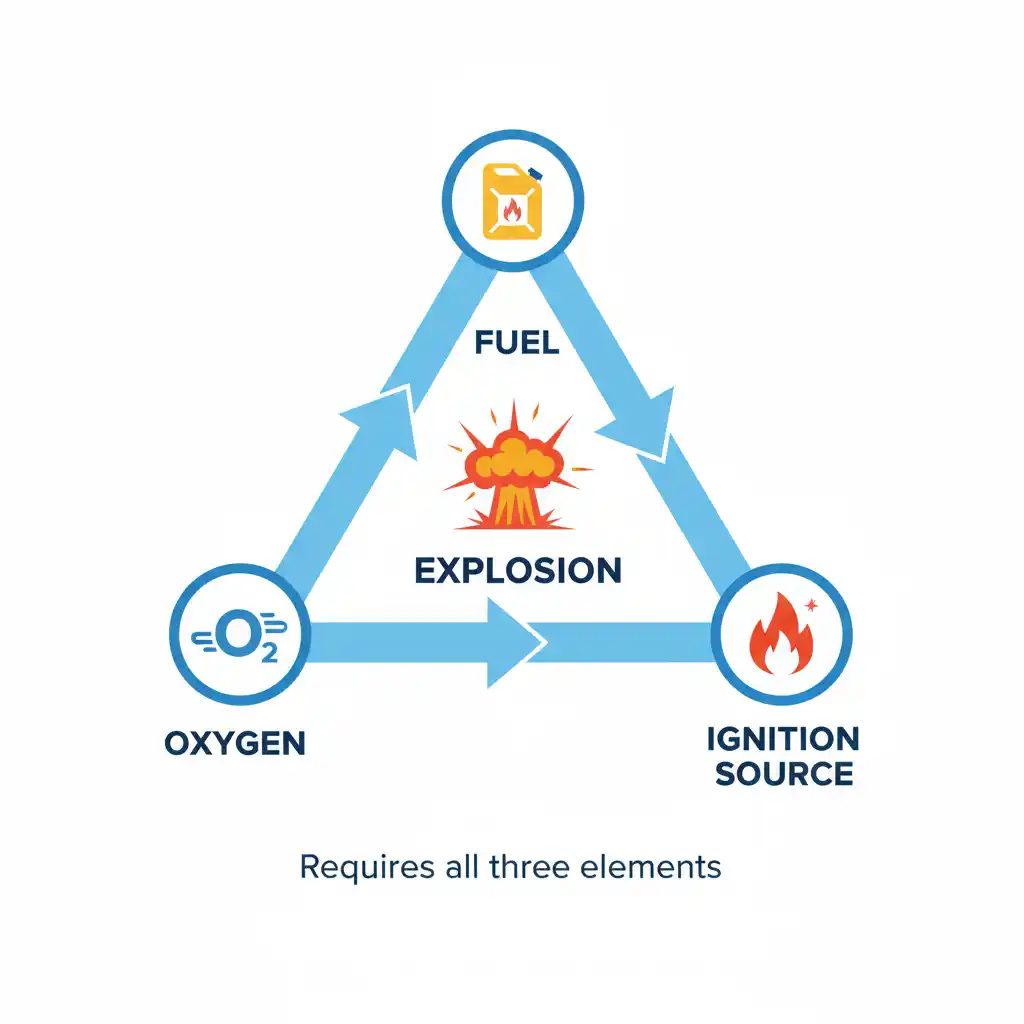

The Danger in a Spark: Understanding the “Explosion Triangle”

To understand the need for explosion-proof equipment, we first need to understand the basics of an explosion. It requires three elements, often called the “Explosion Triangle”:

- Fuel: An explosive substance, such as methane gas in a mine, hydrocarbon vapor in a refinery, or fine grain dust in a silo.

- Oxygen: Present in the ambient air.

- Ignition Source: The most critical element we can control. This could be an open flame, an electrical arc, or even a hot surface.

A standard industrial brake, particularly its electrical actuator, can easily provide an ignition source through normal operational arcing or heat generation. Explosion-proof design is all about eliminating or containing this ignition source.

The Global Safety Languages: ATEX & IECEx Explained

ATEX and IECEx are the two leading sets of standards for equipment used in hazardous areas. While technically very similar, they have different geographical and legal implications.

What is ATEX?

ATEX is derived from the French “ATmosphères EXplosibles” and is a mandatory legal requirement for any equipment sold for use in hazardous environments within the European Union. It consists of two directives (one for manufacturers, one for employers) and is identifiable by the CE and Ex hexagon markings.

What is IECEx?

IECEx is a global, voluntary certification scheme. While not law in itself, it is widely recognized and accepted in countries around the world as the benchmark for safety. Its goal is to create a single international standard, facilitating global trade of compliant equipment. An IECEx certificate provides strong evidence that a product adheres to the highest international safety standards.

Decoding the Markings: What Your Brake’s Label Really Means

The most practical part of these standards is the classification string found on the equipment’s nameplate. Let’s break down a typical example you might find on an explosion-proof thruster: Ex d IIB T4 Gb

Protection Concept: ‘d’ for Flameproof Enclosure

The d signifies that the equipment uses the “flameproof enclosure” method of protection. This is the most common and robust method for equipment like our thrusters. It does not mean the enclosure is sealed to prevent flammable gas from entering.

Instead, the enclosure is built to withstand an internal explosion. If flammable gas enters the thruster’s housing and is ignited by an internal spark, the enclosure is strong enough to contain the explosion. Furthermore, the joints and flanges are precisely engineered to cool any escaping hot gases, preventing them from igniting the surrounding atmosphere.

Equipment Group & Gas Group: ‘IIB’

- Group I is for mining applications (methane and coal dust).

- Group II is for all other above-ground hazardous gas environments. This is further divided:

- IIA: Propane

- IIB: Ethylene (more easily ignited than IIA)

- IIC: Hydrogen, Acetylene (the most easily ignited) A component rated for

IIBis also safe forIIAenvironments, but not forIIC.

Temperature Class: ‘T4’

This is the maximum surface temperature the equipment will reach during operation. The T-class of the equipment must be lower than the auto-ignition temperature of the hazardous substance.

- T1: 450°C

- T2: 300°C

- T3: 200°C

- T4: 135°C

- T5: 100°C

- T6: 85°C

A T4 rating means the equipment will never exceed 135°C, making it safe for gases that ignite above that temperature.

How Our Braking Systems Achieve Compliance

In most industrial brake systems, the brake caliper or drum assembly itself is a simple mechanical device. The component that requires explosion-proof certification is the electrical actuator that releases the brake—the electro-hydraulic thruster.

Our Bed and BYT Series Explosion-Proof Electro-Hydraulic Thrusters are the heart of our compliant braking solutions. They are designed with the flameproof (Ex d) principle at their core, featuring:

- Robust, thick-walled enclosures to contain internal pressure.

- Precisely machined flame paths at all joints to cool escaping gases.

- Secure cable entries that maintain the integrity of the enclosure.

By pairing these certified thrusters with our proven mechanical drum or disc brakes, we deliver a complete, safe, and reliable braking system ready for your hazardous environment.

Your Checklist for Choosing the Right System

When specifying a brake for a hazardous area, ensure you can answer these questions:

- What is the Zone Classification? (e.g., Zone 1, Zone 21)

- What is the Gas or Dust Group? (e.g., IIB)

- What is the required Temperature Class? (e.g., T4 or better)

- What certifications are required? (ATEX for EU, IECEx, or other local standards)

If you are unsure about any of these, it is critical to consult with a safety expert or one of our application engineers. Making the right choice is paramount to the safety of your personnel and facility.

Don’t leave safety to chance. Our team is experienced in providing braking solutions for the world’s most demanding industries. Contact us today to discuss your hazardous environment application.