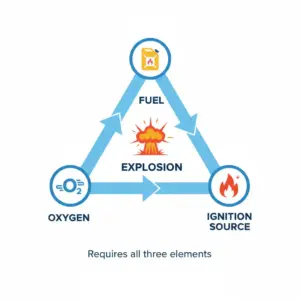

Deep beneath the earth’s surface, the mining environment is a place of immense power and inherent risk. Beyond the heavy machinery and geological pressures, an invisible threat often exists in the atmosphere: flammable gases like methane (firedamp) and combustible coal dust. In this volatile environment, a single spark from a standard piece of electrical equipment can lead to a catastrophic explosion.

This is why specialized, explosion-proof equipment isn’t just a recommendation; it’s a legal and moral imperative. For critical systems like hoists, conveyors, and transport machinery, the braking system is a key component that must be designed to operate safely in these hazardous locations.

The Threat: Methane and Coal Dust

To understand explosion-proof brakes, we must first understand the danger they are designed to mitigate.

- Flammable Gas (Methane): Methane is a natural byproduct of coal seams. If it accumulates in a confined space, it can form an explosive mixture with air.

- Combustible Dust: Fine coal dust can be suspended in the air, creating a cloud that can be ignited with devastating force.

Standard electrical equipment, including the actuators on brakes, can create ignition sources in two ways:

- Sparks: Normal operation of motors, switches, or even a loose connection can create an electrical arc.

- Hot Surfaces: Equipment can heat up during operation to temperatures high enough to ignite a surrounding flammable atmosphere.

The Solution: Principles of Explosion-Proof Design

An explosion-proof brake is not designed to prevent an internal fault. It is designed to contain it. The technology is built on two fundamental principles to ensure an internal event never ignites the outside atmosphere.

1. Containment (Flameproof Enclosures)

The electrical components of the brake actuator, such as the motor inside an Bed Series Explosion-Proof Thruster

2. Surface Temperature Limitation

Every piece of explosion-proof equipment is assigned a “T rating” (e.g., T4 = 135°C). This certifies that the maximum surface temperature the equipment will ever reach during operation is safely below the auto-ignition temperature of the hazardous gases or dusts present.

Decoding the Certifications: What is ATEX Group I?

You cannot simply claim a product is “explosion-proof.” It must be rigorously tested and certified by third-party agencies to international standards like ATEX (Europe) or IECEx (International). For mining, the key designation is Group I.

- Group I: Equipment specifically for use in underground mines susceptible to firedamp.

- Category M2: This is the common category for equipment like brakes. It must be safe during normal operation but can be de-energized in the event of an explosive atmosphere being detected.

When you see a brake actuator marked with the ATEX symbol Ex d I Mb, you know it’s certified as Flameproof (“d”) for Mining (“I”) and meets the M2 protection level (“Mb”).

Critical Applications for Explosion-Proof Brakes in Mining

- Mine Hoists: The primary system for moving personnel and materials in and out of the mine. Brake failure is not an option. Fail-safe, explosion-proof brakes are the only choice for ensuring the hoist can be safely held in any situation.

- Belt Conveyors: Long, powerful conveyors are the arteries of a mine, transporting coal or ore. The brakes on their drive systems are critical for controlled stopping (to prevent belt snap) and for holding inclined conveyors when stopped. The entire drive area requires explosion-proof components.

- Underground Transport: Brakes on personnel carriers, locomotives, and shuttle cars must all meet the stringent safety standards for hazardous locations.

Safety is Not a Compromise

In the mining industry, there is no room for error. Specifying an uncertified brake or a standard industrial brake in a hazardous location is a risk that should never be taken. The integrity of your operation and the lives of your personnel depend on using equipment that is purpose-built and certified for the challenge.

Our BYT and Bed Series Explosion-Proof ThrustersYWZ Series Drum Brakes