Selecting an industrial brake is a task of critical importance. An undersized brake can lead to catastrophic failure, while an oversized brake is an unnecessary capital expense and may not provide the desired control. The key to accurate selection lies in a precise calculation of the required braking torque.

This practical guide is designed for engineers and technicians. We will walk you through a straightforward method for calculating braking torque and discuss the crucial factors beyond the formula that ensure you choose the safest, most effective brake for your application.

Step 1: Gather Your Essential Application Data

Before you can use any formula, you must define the operating parameters. For most applications, especially those driven by an electric motor, you will need:

- Motor Power (P): The power of the motor driving the system, measured in kilowatts (kW).

- Motor Full-Load Speed (n): The rotational speed of the motor at full load, measured in revolutions per minute (RPM). This is typically found on the motor’s nameplate.

- Application Type: The specific job the brake will do (e.g., crane main hoist, conveyor belt, gantry travel).

Step 2: The Core Calculation for Braking Torque (Mb)

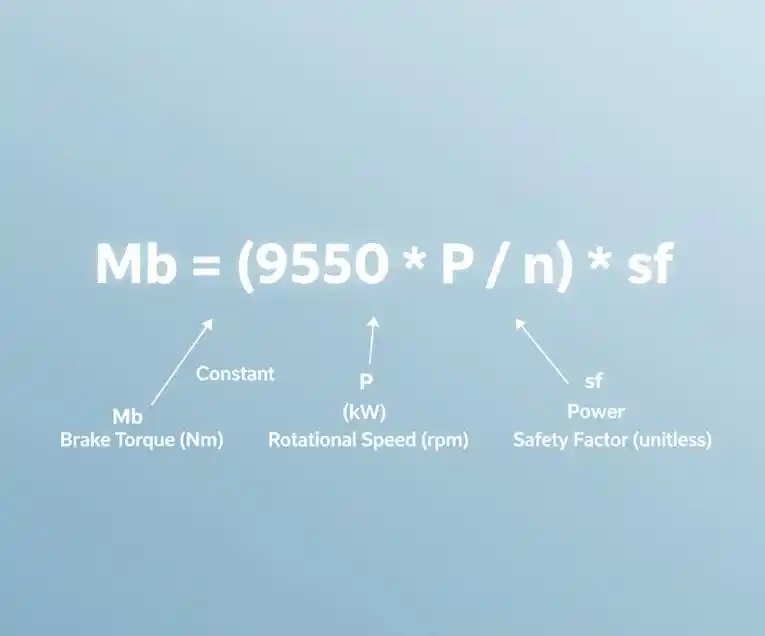

For machinery driven by an electric motor, the required braking torque can be calculated by relating it to the motor’s full-load torque and applying a safety factor. The formula is:

Mb = (9550 * P / n) * sf

Where:

- Mb = Required Braking Torque in Newton-meters (Nm). This is the value you are looking for.

- 9550 = A constant used to convert power in kW and speed in RPM into torque in Nm.

- P = Motor power in kilowatts (kW).

- n = Motor speed in revolutions per minute (RPM).

- sf = Safety Factor (dimensionless).

Step 3: The Critical Choice – Selecting Your Safety Factor (sf)

The Safety Factor is the most important variable in this equation. It is a multiplier that ensures the brake has enough reserve capacity to handle peak loads, emergencies, and wear over its lifespan. Never use a safety factor of 1.0. The appropriate factor depends entirely on the application’s demands and safety criticality.

Recommended Safety Factors by Application

| Application Type | Recommended Safety Factor (sf) | Rationale |

|---|---|---|

| Crane Main Hoist | 1.75 – 2.0 | High risk; must hold the load securely against gravity. |

| Crane Luffing/Boom Hoist | 1.75 – 2.0 | High risk; similar to the main hoist. |

| Conveyor Belts (Level) | 1.50 – 1.75 | Needs to overcome inertia and hold the belt. |

| Conveyor Belts (Inclined) | 1.75 – 2.25 | Must hold the load against gravity, higher risk. |

| Gantry/Trolley Travel | 1.25 – 1.50 | Lower risk; primarily for deceleration and parking. |

| Winches & Lifts | 1.75+ | High risk, especially when lifting personnel or valuable loads. |

Note: Always consult relevant industry standards (e.g., CMAA, DIN) or a brake specialist if you are unsure.

Step 4: Putting It All Together – A Worked Example

Let’s size a brake for the main hoist of an overhead crane.

- Gather Data:

- Motor Power (P) = 30 kW

- Motor Speed (n) = 1450 RPM

- Application = Crane Main Hoist

- Select Safety Factor:

- From our table, a crane hoist requires a high safety factor. Let’s choose sf = 1.75.

- Calculate:

- Mb = (9550 * 30 / 1450) * 1.75

- Mb = (197.59) * 1.75

- Mb = 345.8 Nm

- Select the Brake:

- Now, you would consult our product documentation. You need to choose a brake with a rated static torque that is equal to or greater than 345.8 Nm.

- For example, you might look at our

YWZ4 Series Electro-Hydraulic Drum Brakesand find that the YWZ4-300/50 model has a rated torque of 400 Nm. This would be a suitable choice as it safely exceeds the requirement.

Step 5: Beyond the Numbers – Final Selection Criteria

The calculated torque is your starting point, not your final answer. A professional engineer must also consider these qualitative factors:

Duty Cycle & Heat Dissipation

How often will the brake be applied? For high-cycle applications like a busy production crane, a Fail-Safe Disc Brake is often superior due to its excellent heat dissipation. A drum brake might overheat in such a scenario.

Operating Environment

Will the brake be in a dusty mine, a corrosive marine port, or a clean indoor facility? The enclosed design of a Heavy-Duty Drum Brake is ideal for protecting against contaminants, while special coatings may be needed for corrosive environments.

Fail-Safe Requirement

Is this a safety-critical application where the brake must engage upon power loss? If so, you must select a spring-applied, power-release (fail-safe) brake. All of our hoist and crane brakes, like the SH Series Hydraulic Fail-Safe Brakes, are designed with this principle.

Your Partner in Safe and Reliable Braking

Correct brake calculation is the foundation of safe machinery design. By following this guide, you can confidently determine the torque requirements for your application.

However, every project has unique variables. If you need assistance verifying your calculations or selecting the perfect model that balances performance, longevity, and cost, our technical experts are ready to assist.