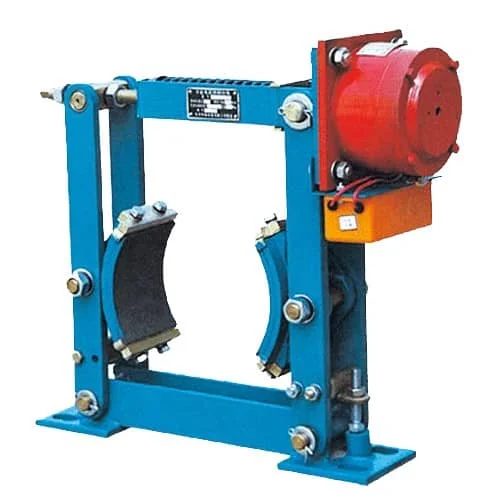

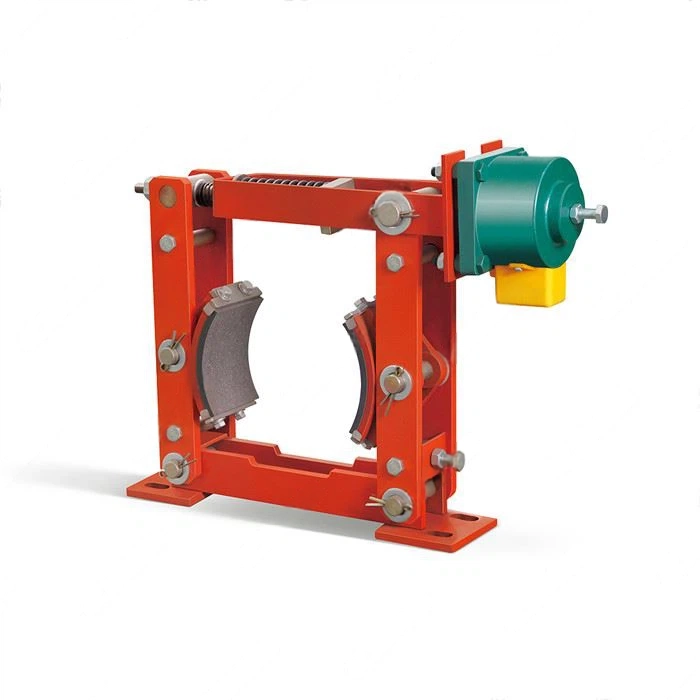

The JZ series electromagnetic drum brakes are engineered to deliver reliable, efficient, and environmentally friendly braking solutions for various industrial applications. Designed in compliance with JB/ZQ4388-1997 and JB/T7685-2006 standards, these brakes feature high-frequency operation, low energy consumption, and a robust construction that ensures long service life.

Ideal for equipment requiring frequent stopping and holding functions, the JZ series utilizes a high-quality electromagnetic coil that provides quick response and stable braking performance. Their green design eliminates asbestos materials, making them safer for operators and environmentally sustainable.

Suitable for operating environments with temperatures from -25°C to 40°C, up to 2000 meters above sea level, and relative humidity below 90%, these brakes are resistant to corrosion and suitable for outdoor or harsh conditions with optional anti-corrosion features. They operate on 380V/50Hz AC power, offering versatility across different industrial sectors such as mining, lifting, and conveyor systems.

In-Depth Specification Analysis with Practical Applications for JZ Series Electromagnetic Drum Brakes

The JZ series electromagnetic drum brakes are meticulously engineered to meet a broad spectrum of industrial requirements. Each model—ranging from JZ-100 to JZ-600—features distinct dimensions and torque capacities that influence installation, operational performance, and maintenance. Understanding these specifications in detail enables engineers and maintenance professionals to select the optimal brake for their specific machinery.

JZ-100

- Dimensions & Installation:

- A = 230mm, D = 100mm, b = 70mm, d = 13mm

- These compact dimensions facilitate easy integration into small-to-medium equipment, with bolt hole spacing and mounting dimensions ensuring compatibility with standard mounting plates.

- Performance & Usage:

- Designed for applications such as small conveyor systems, precision positioning devices, or auxiliary lifting mechanisms where space constraints are critical but reliable braking is required.

- Application Example:

- Suitable for small automated warehouse conveyors, where space-efficient, energy-saving braking ensures smooth operation without occupying excessive room.

JZ-200

- Dimensions & Installation:

- A = 290mm, D = 200mm, b = 80mm, d = 17mm

- Slightly larger size provides increased torque and robustness, supporting more demanding applications.

- Performance & Usage:

- Ideal for medium-duty machinery like hoists, small cranes, or industrial mixers that require frequent stopping and holding.

- Application Example:

- Used in small-to-medium hoisting equipment, where reliable, energy-efficient braking reduces operational costs and extends equipment lifespan.

JZ-300

- Dimensions & Installation:

- A = 385mm, D = 300mm, b = 140mm, d = 22mm

- Larger structural dimensions support higher torque output, suitable for sizable industrial machinery.

- Performance & Usage:

- Suitable for large conveyor belts, heavy-duty lifting devices, or mining equipment that operate under continuous or high-frequency braking cycles.

- Application Example:

- Employed in conveyor systems used in mineral processing plants, where robust braking is essential for safety and process control.

JZ-400

- Dimensions & Installation:

- A = 505mm, D = 400mm, b = 180mm, d = 22mm

- Designed for high-capacity applications, with substantial electromagnetic coil sizes supporting powerful magnetic attraction.

- Performance & Usage:

- Perfect for heavy-duty industrial machinery such as large cranes, steel mills, or continuous operation conveyors.

- Application Example:

- Used in steel production line conveyors, where consistent, high torque braking ensures process stability and safety under demanding conditions.

JZ-500

- Dimensions & Installation:

- A = 577mm, D = 500mm, b = 200mm, d = 22mm

- One of the largest models, capable of handling significant loads with high durability.

- Performance & Usage:

- Suitable for large-scale lifting equipment, heavy-duty mining machinery, or shipyard cranes.

- Application Example:

- Applied in container terminal cranes, where high torque and rapid response are critical for safe and efficient cargo handling.

JZ-600

- Dimensions & Installation:

- A = 675mm, D = 600mm, b = 240mm, d = 26mm

- Maximum dimension and torque capacity in the series, optimized for the most demanding industrial applications.

- Performance & Usage:

- Designed for continuous, high-torque applications such as steel mills, port cranes, or large excavators.

- Application Example:

- Ideal for heavy-duty equipment in metallurgical operations, where safety, reliability, and high performance are paramount.

| Model | A | b | D | d | E | F | G | H | h1 | i | K | M | P | n | G1 |

| JZ-100 | 230 | 70 | 100 | 13 | 165 | 75 | 125 | 300 | 100 | 40 | 110 | 145 | 132 | 6 | 45 |

| JZ-200 | 290 | 80 | 200 | 17 | 215 | 100 | 208 | 435 | 170 | 60 | 175190 | 126 | 132 | 8 | 108 |

| JZ-300 | 385 | 140 | 300 | 22 | 295 | 130 | 290 | 600 | 240 | 80 | 250270 | 160 | 167 | 10 | 140 |

| JZ-400 | 505 | 180 | 400 | 22 | 350 | 180 | 350 | 782 | 320 | 130 | 325 | 210 | 243 | 12 | 190 |

| JZ-500 | 577 | 200 | 500 | 22 | 490 | 200 | 405 | 950 | 400 | 150 | 380 | 250 | 243 | 16 | 225 |

| JZ-600 | 675 | 240 | 600 | 26 | 560 | 220 | 500 | 1160 | 475 | 170 | 475 | 305 | 271 | 18 | 250 |

Each model’s parameters—size, bolt spacing, coil dimensions, and torque capacity—are carefully aligned with specific operational demands. Selecting the appropriate JZ model involves considering the load requirements, installation environment, maintenance accessibility, and safety standards. These detailed specifications serve as a practical reference, guiding precise matching of equipment and ensuring optimal performance, safety, and longevity.