The MW(Z) Series represents the industry standard for reliable, high-frequency braking in heavy-duty lifting and material handling applications. Unlike electro-hydraulic brakes that use a thruster, the MW(Z) series utilizes a powerful DC electromagnet to release the brake. This design offers instantaneous response times, making it the preferred choice for lifting mechanisms where safety and precision are paramount.

How It Works:

- Braking (Power Off): The brake is engaged by the force of a powerful main spring. This presses the brake shoes against the drum, holding the load securely in place. This ensures absolute safety in the event of a power failure.

- Releasing (Power On): When the specialized electromagnetic coil is energized (typically via a rectifier), the armature is attracted to the magnet core. This action overcomes the spring force and moves the lever arms, opening the brake shoes and allowing the machinery to operate.

Features & Benefits:

- Rapid Response: The DC electromagnet provides millisecond-level reaction times, significantly reducing “hook slip” in lifting operations compared to hydraulic alternatives.

- High Operating Frequency: Designed to withstand heavy duty cycles and frequent start/stop operations common in crane usage.

- Compact Design: The electromagnet is mounted directly on the brake arm, saving installation space.

- Easy Maintenance: Features a clear, accessible structure for quick brake shoe replacement and torque adjustment.

- System Integration: Designed to work seamlessly with DKZ Series Power Supply Units (Rectifiers).

Precision, Reliability, and Power for Heavy Industries

When it comes to heavy machinery where safety, responsiveness, and durability are non-negotiable, the MW(Z) series electromagnetic drum brakes stand unmatched. Designed for demanding environments such as lifting, mining, port handling, and construction, these brakes deliver industry-leading performance and peace of mind.

Superior Torque Range for Versatile Applications

The MW(Z) series offers an extensive torque spectrum, from 80 Nm in compact models like MWZ160-80, up to 10,000 Nm in larger units such as MW800-10000. This broad range enables precise matching to your specific load and operational requirements, whether for small cranes or large conveyor systems.

Example Specifications:

- MWZ160-80:

- Brake drum diameter: 160 mm

- Max torque: 80 Nm

- Rated pull force: 1,000 N

- Power supply: DC 220V or AC 380V

- Operating temperature: -25°C to +40°C

- Continuous duty cycle: up to 40%

- MW800-10000:

- Brake drum diameter: 1000 mm

- Max torque: 10,000 Nm

- Rated pull force: 15,000 N

- Power supply: DC 220V / AC 380V

- Operating temperature: -25°C to +40°C

- Advanced cooling systems ensure reliable performance under prolonged use

Robust Construction for Extreme Conditions

Constructed with high-grade steel alloys, advanced sealing, and corrosion-resistant coatings, MW(Z) brakes are built to withstand the most severe industrial environments. Their compact design ensures straightforward installation, while the modular construction simplifies maintenance, reducing downtime and operational costs.

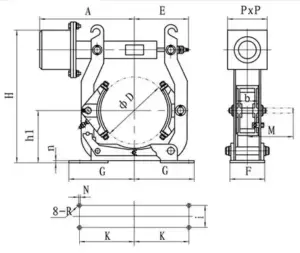

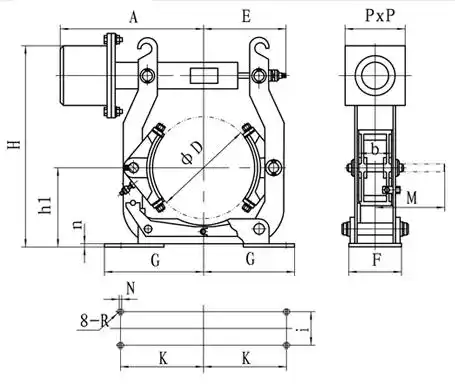

Key Dimensions:

- Mounting hole spacing: Ranges from 100 mm to 1500 mm depending on model

- Overall height: Up to 400 mm for larger units

- Weight: From 15 kg for small models, up to 685 kg for the largest variants

Precise Control & Fast Response

Electromagnetic actuation guarantees rapid engagement and disengagement—critical for automation and safety. The brakes respond within hundreds of milliseconds, ensuring instant holding or release, which minimizes operational delays and boosts productivity.

Electrical Parameters:

- Rated pull force: 1,000 – 15,000 N

- Power consumption: 3A to 14A depending on size

- Voltage options: DC 220V, AC 380V

- Duty cycle: Up to 40% continuous operation

Safety and Monitoring for Critical Operations

Safety is integrated into every MW(Z) brake. Features include:

- Fail-safe spring release for power failure scenarios

- Integrated sensors for real-time monitoring of brake status

- Optional remote control and diagnostic systems, compatible with automation platforms

- Compliance with international standards (ISO, CE, UL)

These features ensure your equipment operates reliably, reducing risk and safeguarding personnel and assets.

Applications That Demand Excellence

This series excels in environments requiring:

- Heavy lifting and crane operation

- Conveyor and hoist systems

- Mining and port handling equipment

- Construction machinery and winches

- Automated industrial machinery

The MW(Z) series delivers seamless, safe braking with minimal maintenance, helping you maximize uptime and safety.

- Unmatched Reliability: Designed for continuous operation under heavy loads.

- Ease of Integration: Compact, modular, and compatible with standard control systems.

- Energy Efficiency: Low power consumption with high actuation force.

- Customizable Options: Different sizes, voltages, and protective features tailored to your needs.

- Proven Industry Leader: Backed by extensive testing, certifications, and global industry experience.

Partner with us for tailored solutions that meet your operational demands. Contact our technical sales team today to discuss your specifications and get a customized proposal. Discover how the MW(Z) electromagnetic drum brake can transform your industrial operations with unmatched safety, precision, and efficiency.