The oil and gas industry, particularly in offshore operations, presents some of the most challenging engineering environments on Earth. From corrosive salt spray to potentially explosive atmospheres, every component must be designed for maximum safety and unwavering reliability. In this context, the braking system on critical machinery like drawworks, winches, and cranes is not just a part—it’s a lifeline.

This technical guide explores the unique challenges faced by braking systems in the oil and gas sector and presents engineered solutions designed to operate flawlessly under the most extreme conditions.

The Unforgiving Environment: Why Standard Brakes Fail

Standard industrial brakes are simply not equipped to handle the triple threat of offshore and oilfield operations:

- Corrosive Atmospheres: Constant exposure to saltwater spray and high humidity rapidly degrades standard materials and coatings, leading to seized components, reduced braking force, and premature failure. Protection conforming to ISO 12944 C5-M (Marine) standards is essential.

- Hazardous Locations (HAZLOC): The presence of flammable gases and dust requires all equipment to be explosion-proof. A single spark from a standard electrical component could be catastrophic. Equipment must be certified to standards like ATEX and IECEx for use in classified zones (e.g., Zone 1, Zone 2).

- Extreme Loads & Non-Stop Operation: Machinery like anchor handling winches and drawworks manage immense dynamic and static loads. Brakes must provide exceptionally high torque and be designed for a long, low-maintenance service life.

Core Principles for Oil & Gas Braking Solutions

To counter these challenges, any braking system deployed in this sector must be built upon three core principles:

- Inherently Fail-Safe Design: The brake must engage automatically in the event of a power or control system failure. The standard is a spring-applied, power-released (hydraulic, pneumatic, or electric) mechanism that guarantees a safe state.

- Certified Explosion-Proof Components: All electrical components, including thrusters and solenoids, must be housed in certified explosion-proof enclosures (e.g.,

Ex d) to prevent ignition of the surrounding atmosphere. - Superior Corrosion Resistance: This is achieved through a multi-layered approach, including marine-grade paint systems, stainless steel for critical components like pins and pistons, and robust sealing.

Our Engineered Braking Solutions for the Oil & Gas Industry

At HMIC, we provide braking systems specifically configured for the demands of offshore and hazardous environments.

For Winches, Cranes, and Tensioners: SH & SP Series Fail-Safe Brakes

Anchor handling winches, mooring winches, and offshore cranes require precise load control and absolute holding power. Our fail-safe caliper brakes are the ideal solution.

- SH Series (Hydraulic) & SP Series (Pneumatic) Fail-Safe Brakes: These brakes offer powerful, spring-applied braking force. For marine applications, they are specially treated with a C5-M compliant coating system and can be fitted with stainless steel hardware to prevent corrosion and ensure reliable release and engagement. Their torque can be precisely modulated for tensioning and rendering applications.

View technical data for our marine-grade SH Series Hydraulic Brakes and SP Series Pneumatic Brakes.

For Drawworks & Hoists in Hazardous Areas: BYT Series Explosion-Proof Thrusters

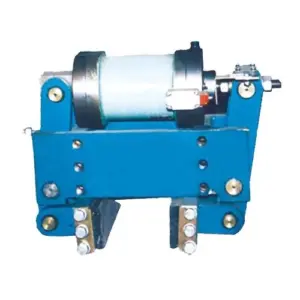

The drawworks on a drilling rig is a safety-critical application often located in a classified hazardous area. Our solution combines a robust drum brake with a certified explosion-proof actuator.

- BYT Series Explosion-Proof Electro-Hydraulic Thrusters: These thrusters are the “engine” that releases the brake. The BYT series is certified to standards such as ATEX Ex d IIC T4 Gb, ensuring it can operate safely in environments containing explosive gases. When paired with our heavy-duty YWZ-series drum brakes, they form a complete, certified braking system that delivers reliable, fail-safe performance with thrust ratings from 500N to 3000N.

Learn more about our certified BYT Series Explosion-Proof Thrusters for hazardous locations.

Quick Selection Reference Table: Oil & Gas Brakes

| Application | Key Challenges | Recommended Solution | Core Features |

|---|---|---|---|

| Mooring & Anchor Winches | High static loads, extreme corrosion, precise tension control. | SH / SP Series Fail-Safe Brakes | C5-M marine coating, stainless steel parts, fail-safe design, high holding torque. |

| Offshore Cranes (Hoisting) | Fail-safe holding, corrosion, dynamic stopping. | SH Series Hydraulic Brakes or BYT-Actuated Drum Brakes | Fail-safe operation, high thermal capacity, marine-grade finishing. |

| Drilling Rig Drawworks | High dynamic energy, explosive atmosphere (ATEX), fail-safe requirement. | YWZ Drum Brake + BYT Series Thruster | ATEX Ex d certified thruster, robust mechanical brake, high reliability. |

| Pipe Handling Systems | Precise positioning, potential hazardous area, high cycling. | CQP / QP Series Pneumatic Brakes + Explosion-Proof Solenoid | Fast response time, compact design, configurable for ATEX environments. |

Safety and Reliability Are Non-Negotiable

In the high-stakes world of oil and gas, there is no room for compromise on safety or reliability. Selecting a braking system is a critical decision that directly impacts operational integrity and personnel safety. By choosing brakes specifically engineered and certified for corrosive and hazardous environments, you ensure your equipment is prepared for the challenge.