In a thermal power plant, the coal handling system is the artery that feeds the heart of the operation. A steady, reliable flow of fuel from the yard to the boiler is non-negotiable. Any interruption in this flow—even for a few hours—can impact power generation and lead to significant financial losses.

While the conveyor belt itself gets a lot of attention, the braking system that controls it is often the unsung hero responsible for ensuring this critical reliability. This guide explains the unique braking challenges of power plant conveyors and details the engineering solution required to ensure maximum uptime and safety.

The Core Challenge: Controlling Massive Inertia

A long, inclined conveyor belt loaded with tons of coal represents a massive amount of kinetic and potential energy. Managing this energy during a stop is the primary challenge. This breaks down into two distinct, high-risk scenarios.

The Danger of Rollback

When an inclined conveyor stops, gravity immediately wants to pull the entire loaded belt backward. An uncontrolled rollback can cause:

- Catastrophic Spillage: Tons of coal spilling at the loading point, requiring a massive and costly cleanup operation.

- Equipment Damage: The motor can be forced to spin backward at high speed, and the entire system can be subjected to immense structural stress.

- Extreme Safety Hazards: Uncontrolled moving machinery poses a direct threat to any personnel in the area.

This is why a simple service brake is not enough. A reliable fail-safe holdback is essential.

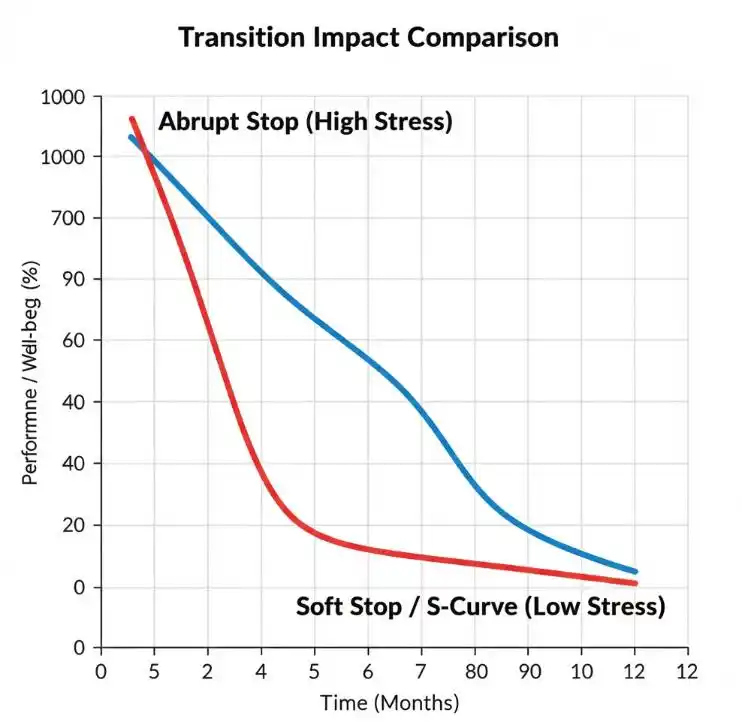

The Violence of an Abrupt Stop

Just as dangerous as rollback is stopping too suddenly. Imagine slamming on the brakes of a fully loaded freight train. The immense inertia creates a shockwave that travels through the system. On a conveyor, this results in:

- Extreme Belt Tension: This shock load can stretch or even snap the conveyor belt—an incredibly expensive and time-consuming component to replace.

- Drive and Component Stress: The gearbox, couplings, and drive motor are subjected to violent forces that can lead to premature failure.

Beyond Simple Stopping: The Art of the “Soft Stop”

The solution is not just a brake that can hold the load, but a brake that can bring the load to a stop in a controlled, gentle manner. This is known as a “soft stop” or an “S-Curve” deceleration profile.

Instead of instantly applying 100% braking force, a soft braking system applies the torque in stages. This allows the belt’s inertia to dissipate smoothly, eliminating the damaging shockwave.

The Solution in Practice: Two-Step Braking Systems

This controlled stop is achieved with an intelligent braking solution like a two-step brake. It operates on a simple, brilliant principle:

- Step One (Initial Soft Brake): Upon the stop signal, the brake applies a pre-set, lower braking torque. This initiates a gentle deceleration, absorbing the bulk of the kinetic energy smoothly.

- Step Two (Full Hold): After a short, pre-defined time delay (e.g., 1-3 seconds), once the belt has slowed significantly, the brake applies its full braking torque to bring the belt to a complete halt and hold it securely.

This entire process is, of course, built on a fail-safe foundation. If power is lost at any point, the brake will automatically engage to prevent rollback.

Your Checklist for a Reliable Conveyor Braking System

When specifying a brake for a critical coal conveyor, ensure it meets these four criteria:

- Inherently Fail-Safe: It must default to the “braked” state on any loss of power.

- Controlled (Soft) Braking Capability: It must have a feature like two-step braking to prevent shock loads. Our

YW-E Series Two-Step Electro-Hydraulic Drum Brakesare engineered specifically for this purpose. - High Static Holding Torque: It must have ample power to securely hold a fully loaded belt on the maximum incline.

- Durability and Low Maintenance: It must be a robust, heavy-duty design (like an enclosed drum brake) that can withstand the dusty power plant environment with minimal intervention.

Conclusion: A Smart Brake is a Reliable Plant

The braking system on your coal conveyor is more than just a stopping device; it’s an insurance policy against catastrophic failure and unplanned downtime. Investing in an intelligent, soft-braking solution protects your most expensive assets—like the conveyor belt itself—and ensures the artery of your plant continues to feed your operations without interruption.