High-Performance Industrial Disc Brakes

Precision control and reliable stopping power with our hydraulic, pneumatic, and fail-safe disc brake solutions.

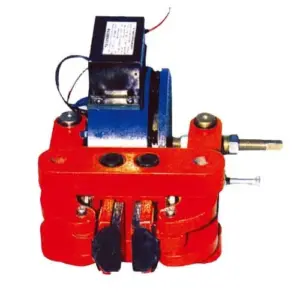

Disc brakes use brake pads to clamp onto a disc that rotates with the wheel or axle, generating friction torque for precise and smooth braking. We offer a full range of disc brakes, from hydraulic direct-acting to electromagnetic fail-safe models. These are widely used in industries such as lifting, metallurgy, ports, and wind power, meeting high-speed or emergency braking needs under diverse operating conditions.