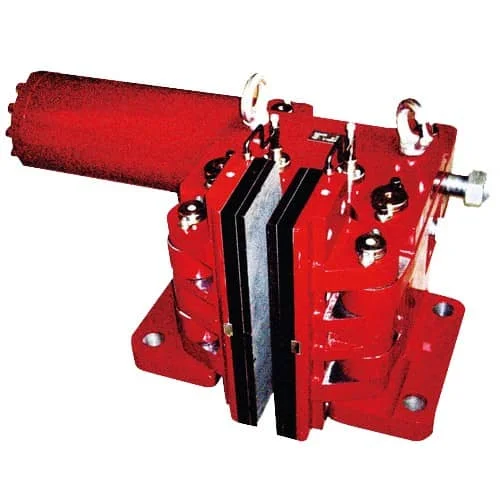

Надёжное решение для тяжёлых промышленных тормозных систем

В тяжелых промышленных приложениях, таких как краны, горное дело и портовое оборудование, надежность тормозной системы является критическим фактором для обеспечения безопасной и эффективной работы оборудования. Гидравлический тормоз с безопасным отключением серии SDBH-I разработан и изготовлен в соответствии со стандартом JB/T10917-2008 "Клапанный дисковый тормоз", с целью обеспечения стабильной и безопасной тормозной защиты для различных критически важных промышленных устройств. Эта серия продуктов эффективно решает строгие задачи по производительности тормозов и надежности в промышленных условиях благодаря своим уникальным принципам дизайна, точному контролю эксплуатационных параметров и интегрированным функциям мониторинга состояния.

Основной механизм: Встроенная способность защиты от отказов

Тормоза серии SDBH-I имеют конструкцию с нормально закрытым типом и принципом гидравлического освобождения. Эта конструкция обеспечивает автоматическое и быстрое зажатие тормозного диска в неожиданных условиях, таких как отключение питания, потеря давления в гидравлической системе или аварийная остановка. Например, при нормальных условиях эксплуатации система поддерживает тормоз в освобожденном состоянии, используя рабочее давление масла 8-9,5 МПа (в зависимости от модели, например, 8 МПа для SDBH250-I и SDBH365-I, и 9 МПа для SDBH425-I); как только давление масла падает ниже установленного порога или исчезает, тормоз немедленно возвращается в зажатое состояние, обеспечивая встроенную защиту от отказов и эффективно снижая риски для безопасности и повреждения оборудования, вызванные отказами тормозов.

Точная работа и высокая адаптивность

- Точное управление зазорами: оптимизация срока службы трения

- Одной из основных конструктивных особенностей этой серии тормозов является полностью автоматический механизм слежения за положением. Этот механизм обеспечивает точное управление односторонним зазором между фрикционной пластиной и тормозным диском в диапазоне от 1 мм до 2 мм, когда тормоз находится в освобожденном состоянии. Это точное управление зазором эффективно предотвращает распространенные проблемы, такие как локализованный износ или "плавающая адгезия" фрикционной пластины в традиционных тормозах, значительно продлевая срок службы фрикционной пластины, уменьшая частоту замены запасных частей и затраты на обслуживание, а также повышая общую операционную эффективность.

- Гибкая возможность регулировки установки: Адаптация к условиям на месте

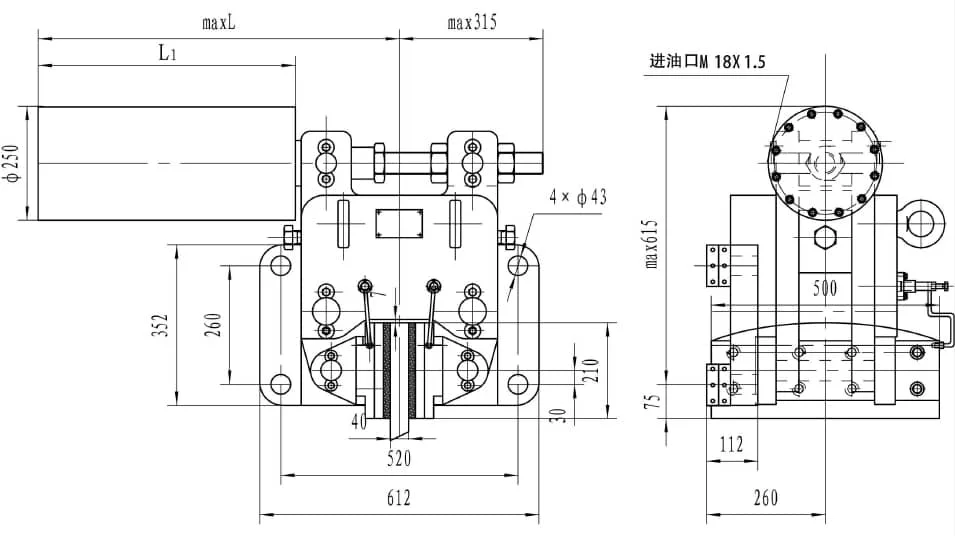

- Учитывая сложные условия установки в промышленных условиях, тормоза серии SDBH-I имеют регулируемую высоту центра. Эта функция позволяет точно настраивать высоту тормоза во время установки, чтобы эффективно компенсировать любые ошибки установки, которые могут возникнуть на месте. Например, даже для различных моделей тормозов разных размеров — таких как модель SDBH250-I с размером L 595 мм и модели SDBH365-I и SDBH425-I с размером L 790 мм — регулируемая функция значительно упрощает процессы выравнивания и пусконаладки на месте, улучшая эффективность установки и адаптивность оборудования.

- Стандартизированные гидравлические интерфейсы и адаптивность к окружающей среде:

- Все модели серии SDBH-I, включая SDBH250-I, SDBH365-I и SDBH425-I, демонстрируют высокую стандартизацию и эффективность в гидравлическом управлении: они единообразно используют объем масла в цилиндре 275 мл, что упрощает проектирование и обслуживание гидравлической системы. Кроме того, все модели могут стабильно работать в диапазоне температур окружающей среды от -5°C до 40°C, что охватывает температурные требования большинства промышленных приложений.

Интеллектуальный мониторинг и поддержка обслуживания

Тормоза серии SDBH-I оснащены функцией широковольтного открытия AC/DC, что обеспечивает надежную работу в различных условиях электропитания. Ключевым элементом является интегрированный датчик износа. Этот датчик может в реальном времени отслеживать состояние износа фрикционных пластин и может быть подключен к системе управления оборудованием для достижения защиты с блокировкой и сигнализации о неисправностях. Например, когда износ фрикционных пластин приближается к предельному значению безопасности, система может проактивно выдать сигнал тревоги, побуждая обслуживающий персонал выполнить плановую замену, чтобы избежать аварийных остановок, вызванных неожиданным износом. Эта функция поддерживает стратегии предиктивного обслуживания на основе состояния, эффективно снижая риск незапланированных простоя и тем самым повышая общую доступность и эксплуатационную безопасность оборудования.

Серии продуктов и совместимость с приложениями

Серия SDBH-I предлагает модели с различными номинальными силами зажима (кН) и тормозными силами (кН) для удовлетворения разнообразных требований промышленных приложений:

- Модель SDBH250-I: Номинальная сила зажима 250 кН, создающая тормозную силу 180 кН. Вес корпуса составляет 660 кг, размер L1 равен 378 мм. Эта модель обычно используется в подъемных механизмах средних и малых кранов, а также в шахтных лебедках с относительно умеренной мощностью, обеспечивая стандартную защиту от торможения для этих устройств.

- Модель SDBH365-I: Сила зажима увеличена до 365 кН, а сила торможения достигает 262 кН. Хотя его длина L такая же, как у SDBH425-I и составляет 790 мм, его более тяжелый корпус весом 720 кг и длина L1 в 570 мм делают его подходящим для подъемных механизмов портового и терминального оборудования или подъемников среднего и большого размера, обеспечивая улучшенные характеристики торможения.

- Модель SDBH425-I: Будучи моделью с самой высокой тормозной силой в серии SDBH-I, SDBH425-I имеет номинальную зажимную силу до 425 кН и тормозную силу 306 кН. Его длина составляет 790 мм, но благодаря внутреннему структурному усилению вес корпуса увеличился до 730 кг. Эта модель специально разработана для высокомощных наклонных ленточных конвейеров, крупных литейных кранов и другого тяжелого оборудования с высокой инерцией, обеспечивая исключительные рабочие тормозные и аварийные тормозные возможности.

Обеспечение надежности и производительности

Гидравлические дисковые тормоза SDBH-I серии с функцией аварийного торможения предлагают стабильное и надежное решение для торможения тяжелого промышленного оборудования, обладая встроенными механизмами аварийного торможения, точным контролем параметров торможения, адаптивностью к установке и интеллектуальными функциями мониторинга. Мы стремимся предоставлять продукцию, соответствующую отраслевым стандартам, с прозрачными данными о производительности, с целью помочь клиентам обеспечить безопасность производства и оптимизировать эффективность работы оборудования.

Для получения более подробных технических характеристик или выбора продукта на основе ваших конкретных условий эксплуатации, пожалуйста, свяжитесь с нашей технической поддержкой.