Обзор

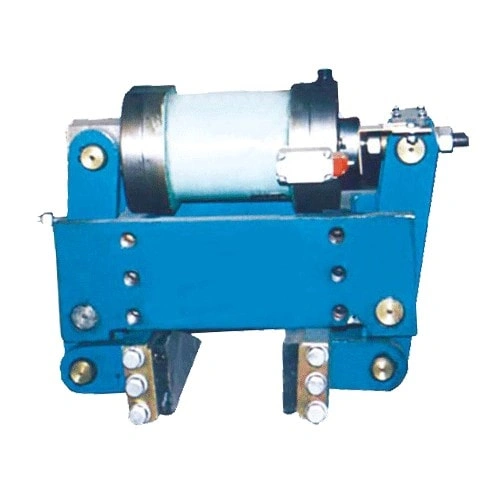

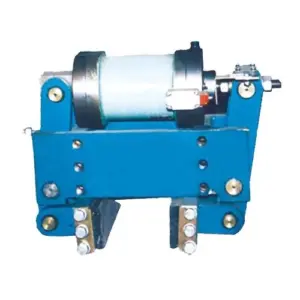

The YLBZ series hydraulic wheel side brake is a high-performance hydraulic braking device designed to meet stringent braking requirements in various industrial applications. This brake is renowned for its exceptional clamping and braking force, making it suitable for use in diverse environmental conditions, ensuring stability and safety during operation.

Преимущества

- Надежное тормозное усилие: Серия YLBZ предлагает множество спецификаций для удовлетворения различных потребностей. Например, модель YLBZ25-160 имеет номинальное усилие зажима 50 KN и тормозное усилие 42 KN, в то время как модель YLBZ100-200 обеспечивает усилие зажима до 180 KN и тормозное усилие 150 KN. Эти показатели обеспечивают надежность и эффективность в процессе эксплуатации.

- Долговечность и адаптивность: Разработанный с учетом факторов окружающей среды, прибор может нормально работать в диапазоне температур от -5℃ до 40℃. Для работы на открытом воздухе или в агрессивных средах предлагаются специально разработанные антикоррозийные модели, значительно продлевающие срок службы оборудования.

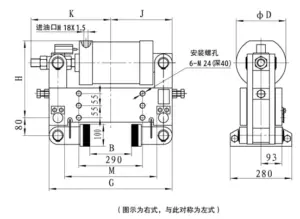

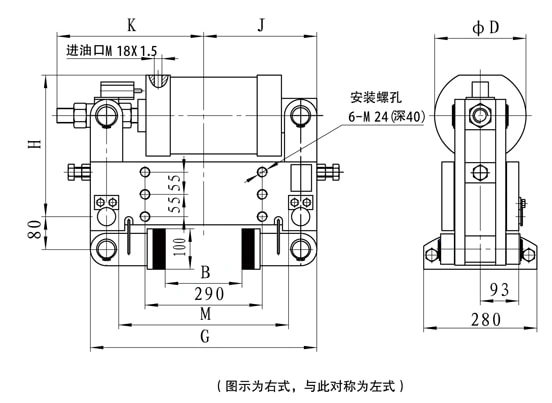

- Настраиваемые размеры: Серия YLBZ предлагает различные варианты размеров, например, YLBZ40-160 с размером 160 мм и YLBZ63-210 с размером 210 мм. Такие разнообразные характеристики позволяют гибко адаптировать продукт к различным конфигурациям оборудования.

Диапазон применения

Гидравлический боковой тормоз для колес YLBZ широко используется в тяжелой технике, горнодобывающем оборудовании, портовых кранах и других сценариях, требующих эффективного торможения. Его мощная тормозная способность превосходно работает в сложных условиях эксплуатации, что делает его критически важным компонентом для обеспечения безопасной работы оборудования.

Принцип работы

Гидравлические тормоза достигают тормозного эффекта за счет давления, создаваемого гидравлическим маслом. Рабочее давление остается на уровне 8 МПа, позволяя гидроцилиндру давить на тормозной диск, зажимающий сторону колеса для достижения торможения. Различные модели тормозов, в зависимости от их силы зажима и торможения, могут адаптироваться к различным весам оборудования и эксплуатационным потребностям.

Метод использования

- Установка: Выберите подходящую модель тормоза, исходя из конкретных размеров и технических характеристик оборудования. Во время установки убедитесь, что все соединения надежны, а гидравлические линии не имеют утечек.

- Осмотр и обслуживание: Регулярно проверяйте силу зажатия и торможения тормоза, убедитесь в отсутствии утечек в гидравлической системе. Для оборудования, используемого вне помещений, уделяйте особое внимание антикоррозийным мерам, чтобы продлить срок службы.

- Условия эксплуатации: Убедитесь, что температура рабочей среды поддерживается в диапазоне от -5℃ до 40℃, чтобы избежать влияния экстремальных условий на работу тормоза.

Общие проблемы клиентов

1. Как тормоз обеспечивает долговечность в агрессивных средах?

Гидравлический боковой тормоз для колес серии YLBZ специально разработан с использованием антикоррозийных материалов и подходит для работы в условиях дождя, снежной эрозии или агрессивных газов и сред. При регулярном обслуживании и использовании соответствующих антикоррозийных материалов оборудование может сохранять работоспособность в таких суровых условиях.

2. Может ли продукт работать при экстремальных температурах?

Тормоз YLBZ обеспечивает стабильную работу в диапазоне температур от -5℃ до 40℃. При экстремальных температурах для обеспечения нормальной работы следует применять дополнительные меры защиты, такие как системы обогрева или охлаждения.

3. Как выбрать правильную модель?

При выборе подходящей модели необходимо учитывать размер, вес и специфические потребности оборудования в торможении. Серия YLBZ предлагает различные спецификации, такие как YLBZ25-160, YLBZ63-180 и т.д., позволяя пользователям выбирать на основе номинальных параметров зажима и тормозного усилия для обеспечения оптимальной совместимости.

Заключение

Гидравлический боковой тормоз для колес серии YLBZ, обладающий мощной производительностью и широкими возможностями применения, является идеальным выбором в промышленном секторе. Выбрав подходящую модель и применив правильные методы обслуживания и использования, клиенты смогут обеспечить безопасную и эффективную работу в различных условиях. Будь то горнодобывающая промышленность, порты или другие промышленные объекты, тормоз YLBZ обеспечивает надежное торможение.

Таблица параметров

| Технические характеристики | Зажимное усилие | Тормозное усилие | Размер | Вес кг | ||||||

| KN | KN | B | K | J | H | D | G | M | ||

| YLBZ25-160 | 50 | 42 | 160 | 300 | 250 | 310 | 190 | 500 | 370 | 145 |

| YLBZ40-150 | 73 | 63 | 150 | 325 | 150 | |||||

| YLBZ40-160 | 160 | |||||||||

| YLBZ40-180 | 180 | |||||||||

| YLBZ40-200 | 200 | |||||||||

| YLBZ63-180 | 114 | 96 | 180 | 200 | 510 | 370 | 155 | |||

| YLBZ63-200 | 200 | |||||||||

| YLBZ63-210 | 210 | |||||||||

| YLBZ100-200 | 180 | 150 | 200 | 360 | 280 | 350 | 225 | 560 | 420 | 160 |

Examples:

YLBZ25-160: Series Code (YLBZ): Indicates the YLBZ series.

Wheel Load (25): Supports a wheel load of 250 KN.

Wheel Width (160): Designed for a wheel width of 160 mm.

Special Requirements: None specified.

YLBZ40-150: Series Code (YLBZ): Indicates the YLBZ series.

Wheel Load (40): Supports a wheel load of 400 KN.

Wheel Width (150): Designed for a wheel width of 150 mm.

Special Requirements: None specified.

YLBZ63-180: Series Code (YLBZ): Indicates the YLBZ series.

Wheel Load (63): Supports a wheel load of 630 KN.

Wheel Width (180): Designed for a wheel width of 180 mm.

Special Requirements: None specified.

YLBZ100-200: Series Code (YLBZ): Indicates the YLBZ series.

Wheel Load (100): Supports a wheel load of 1000 KN.

Wheel Width (200): Designed for a wheel width of 200 mm.

Special Requirements: None specified.