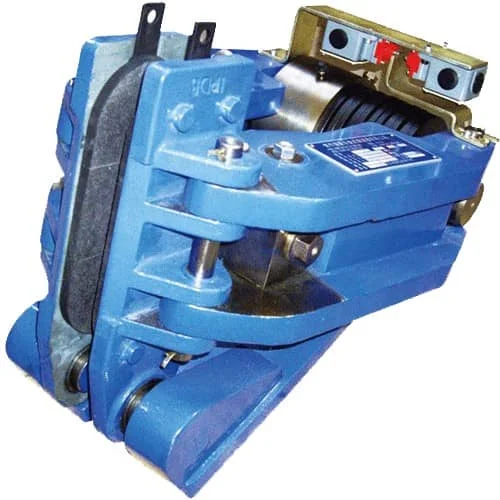

In the industrial sector, safety and reliability are critical to maintaining operational efficiency and personnel protection. The SH series hydraulic fail-safe disc brakes deliver precise performance backed by detailed technical specifications, making them essential for high-demand applications.

These brakes feature a compact design with rotor diameters ranging from 190mm in models like the 5SH to 600mm in larger variants such as the ST40SH. Corresponding torque capacities vary from 165 Nm to 2880 Nm. For example, the ST25SH-C model can generate a maximum braking force of 180,000N (180kN). The braking torque is calculated based on the formula:

N.m = (Braking Force (N) / 1000) × (ΦB/2 - 60 or 75)

where ΦB is the brake disc diameter. This precise calculation ensures the brake’s torque output aligns with specific equipment requirements.

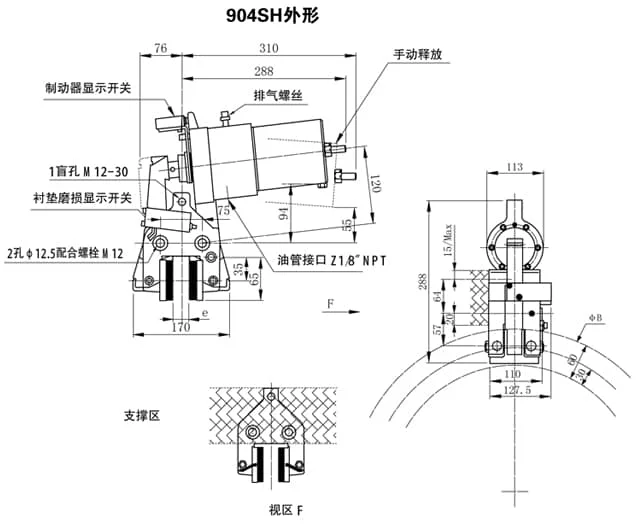

Response time for all models is zero seconds, which ensures immediate activation during emergency stop scenarios. For instance, the 904SH model has an instantaneous response with a fully released displacement volume of 33cm³ and a cylinder capacity of 98cm³, allowing rapid fluid pressure transmission and minimizing brake delay—crucial for safety in cranes, mining machinery, and port handling equipment.

Maximum braking forces differ across models: the ST16SH offers up to 150kN, while the ST10SH provides around 81kN, enabling tailored solutions for various load demands. Cylinder volumes range from 275ml (ST10SH) to 810ml (ST40SH), ensuring consistent pressure application and brake stability.

Installation accuracy is maintained with a maximum disc face runout of ±0.2mm and a perpendicularity deviation of no more than ±4‰. High-strength fasteners, such as M36 bolts graded 12.9 with tightening torque up to 4,280 Nm, guarantee secure mounting under heavy loads.

Environmental resistance is also a key feature. For outdoor or corrosive environments, certain models are available with corrosion-resistant coatings, suitable for use in harsh conditions like high humidity, salt spray, or exposure to aggressive gases. For example, the ST25SH-A model withstands release pressures up to 190 bar, with a fully released displacement volume of 95ml, ensuring consistent performance even under extreme weather.

Automatic wear compensation mechanisms, such as wear line detection on friction pads, maintain stable braking torque over the component’s lifespan, reducing maintenance frequency. The 450SH model’s wear indicator enables real-time monitoring to prevent brake failure due to excessive pad wear.

In summary, the SH series hydraulic fail-safe disc brakes combine precise torque control, rapid response, durable construction, and environmental resilience. These features address core customer needs for safety, reliability, and ease of maintenance in demanding industrial applications, providing a dependable braking solution for critical machinery across a range of high-risk sectors.