GET QUOTATION

Please leave us a message, and we will reply within 12 hours.

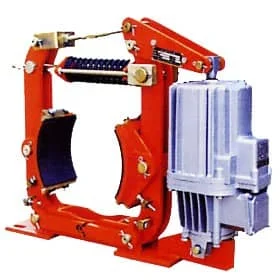

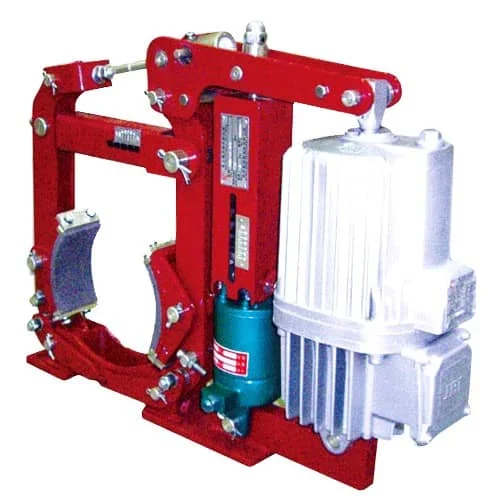

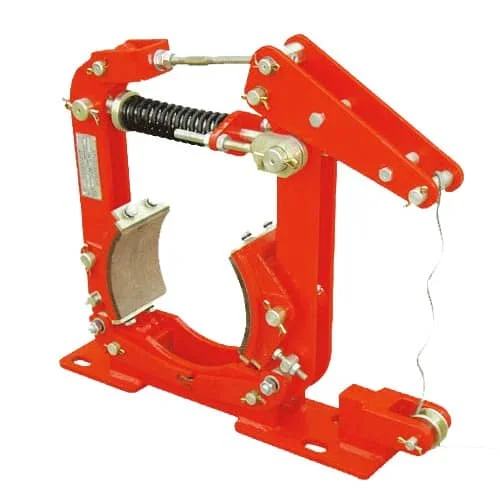

In the context of cranes, industrial brakes are non-negotiable, mission-critical safety devices that govern load control and motion. They are most critically applied to the hoist mechanism as primary holding brakes, typically of a spring-applied, power-released (fail-safe) design. Their function is to automatically and securely hold the load suspended in a static position the instant motor power is cut or lost, thereby preventing catastrophic load drops. Beyond hoisting, brakes are also integral to the crane’s other axes of motion: the trolley (traverse), bridge/gantry (travel), and boom (slewing). In these applications, they provide controlled dynamic deceleration for accurate load positioning and also act as parking brakes to hold the structure stationary against inertia, drive system backlash, or external forces like wind. The selection and condition of a crane’s brakes directly determine its operational safety and its compliance with stringent industry safety standards.

Please leave us a message, and we will reply within 12 hours.