GET QUOTATION

Please leave us a message, and we will reply within 12 hours.

In heavy industry, a Safety Brake System is an engineered set of components designed to prevent catastrophic failure by bringing machinery to a controlled stop or holding it securely in a static position, especially during a power loss or emergency event. Unlike a primary service brake used for normal operational stopping, a safety brake functions as a redundant, ultimate line of defense.

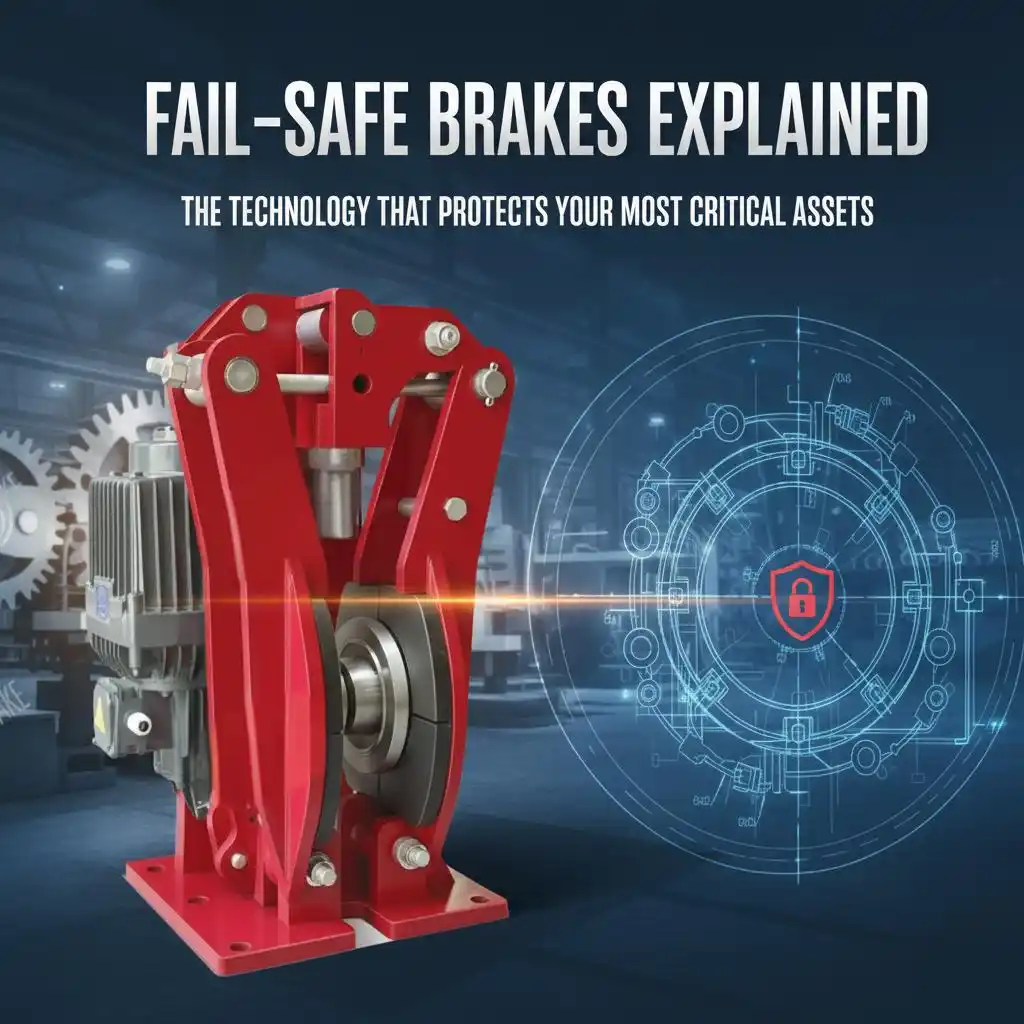

The core engineering principle that defines a true industrial safety brake system is its fail-safe design.

The Fail-Safe Principle: The Heart of Industrial Safety

A fail-safe brake is mechanically engaged by a reliable, non-energized source, such as a set of powerful compression springs or gravity. Energy (typically hydraulic, pneumatic, or electrical) is required to disengage or release the brake, allowing the machine to operate.

This design philosophy is critical:

This is the direct opposite of an active braking system that requires power and a control signal to apply the brake. An industrial safety brake’s reliability comes from its inherent tendency to engage in the absence of energy.

Components and Applications

A Safety Brake System is not a single part but an integrated solution that can include:

Distinction from Service Brakes

It is crucial to differentiate between the two:

A Safety Brake System is the ultimate safeguard for high-value industrial assets and, most importantly, for human life. Its fail-safe design ensures that it performs its critical function when it is needed most—during an unexpected loss of power or system control, providing a guaranteed and reliable final layer of protection.

Please leave us a message, and we will reply within 12 hours.