GET QUOTATION

Please leave us a message, and we will reply within 12 hours.

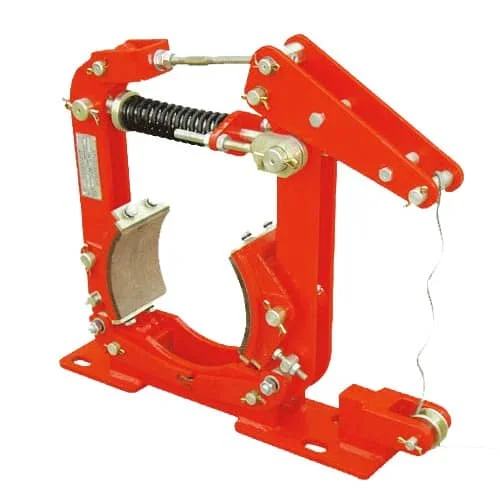

In heavy industry, the Service Brake is the primary, power-applied braking system designed for all routine and operational stopping tasks. It is the active “workhorse” brake used to dynamically decelerate a machine, control its speed, and bring it to a precise stop under normal working conditions. Its design is fundamentally centered on energy management and durability over thousands of operational cycles.

The Core Function: Dynamic Energy Dissipation

Unlike a static holding or emergency brake, the primary function of a Service Brake is to manage kinetic energy. During a stop, it converts the immense motional energy of a machine—be it a loaded crane, a moving conveyor, or a rotating mill—into heat, and then effectively dissipates that heat into the environment. This thermal capacity is the most critical aspect of its design, ensuring consistent, fade-free performance, stop after stop.

Key Design and Operational Characteristics

The Critical Distinction: Service Brake vs. Safety Brake

Understanding the difference between these two systems is fundamental to industrial safety and engineering. They are designed for entirely different purposes and are not interchangeable.

| Characteristic | Service Brake | Safety Brake (Emergency / Parking Brake) |

|---|---|---|

| Primary Function | Dynamic stopping, speed control (doing work) | Static holding, emergency stopping (preventing failure) |

| Actuation Method | Power-Applied (Requires energy to stop) | Spring-Applied / Fail-Safe (Requires energy to release) |

| Design Priority | Heat dissipation, controllability, wear life | Absolute holding power, reliability, fail-safe action |

| Typical Use | Frequent, normal operational stops | Rare emergency stops, static parking/holding |

Typical Applications

In conclusion, the Service Brake is the essential tool for the active control of industrial machinery. It is a system engineered for a life of dynamic work, defined by its power-applied nature and its capacity to manage immense energy, setting it fundamentally apart from the passive, fail-safe systems that provide ultimate protection.