Technical Overview and Application Guide

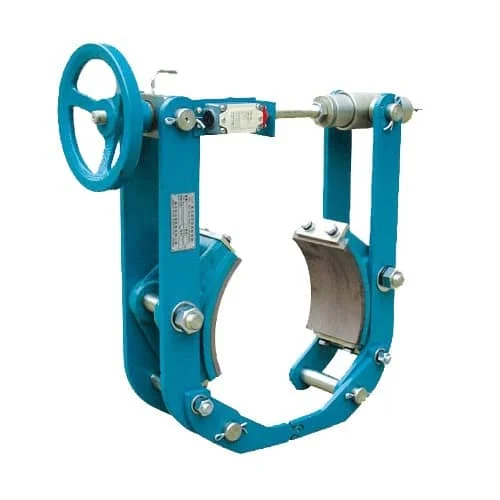

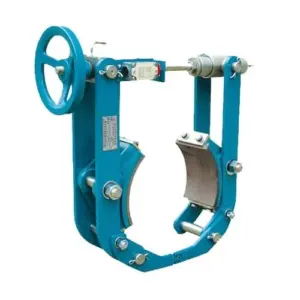

The TYW series is a hydraulically actuated, normally open, horizontally mounted drum brake. Controlled via a foot-operated hydraulic pump, it is primarily used in the slewing mechanisms of small to medium-sized portal and tower cranes. A manual locking device allows braking when the system is not pressurized.

In industrial motion control systems, braking components must meet strict performance, safety, and durability requirements. The TYW Series Hydraulic Drum Brakes are designed for medium to heavy-duty applications where consistent torque, compact integration, and low maintenance are essential. This article provides a technical breakdown of the TYW series, based on verified specifications, and addresses key considerations for engineers and procurement professionals evaluating hydraulic drum brake systems.

1. Application Context: Why Hydraulic Drum Brakes?

Hydraulic drum brakes are widely used in lifting, hoisting, and conveying systems due to their ability to deliver high braking torque with precise control. Unlike mechanical or pneumatic systems, hydraulic actuation offers smoother response and better modulation under variable loads. This makes them particularly suitable for:

- Overhead cranes and gantry cranes

- Port handling equipment

- Mining conveyors and winches

- Steel mill rolling lines

- Industrial elevators and hoists

The TYW Series is engineered to meet these demands with a range of models that support different torque and dimensional requirements.

2. Technical Specifications Overview

The TYW Series includes four primary models: TYW-300, TYW-315, TYW-400, and TYW-500. Each model is defined by its rated braking torque, hydraulic pressure range, and drum diameter. The table below summarizes the key parameters:

| Model | Rated Braking Torque (Nm) | Operating Pressure (MPa) | Drum Diameter (mm) | Weight (kg) |

|---|---|---|---|---|

| TYW-300 | 200–400 | 4.5–6.0 | 300 | 40 |

| TYW-315 | 200–400 | 4.5–6.0 | 315 | 42 |

| TYW-400 | 600–800 | 4.5–6.0 | 400 | 50 |

| TYW-500 | 1400 | 2.0 | 500 | 80 |

Key Observations:

- The TYW-500 model delivers the highest torque (1400 Nm) at a lower hydraulic pressure (2.0 MPa), making it suitable for high-load applications with limited hydraulic capacity.

- TYW-300 and TYW-315 share the same torque range but differ in drum diameter and mounting dimensions, offering flexibility in system design.

- The weight of each unit increases proportionally with torque capacity, which is a critical factor in structural load calculations.

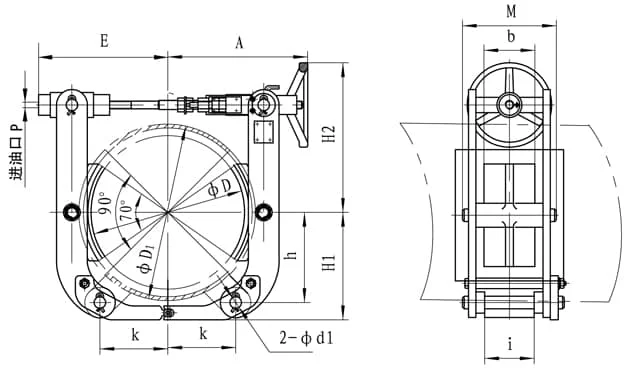

3. Dimensional Considerations for System Integration

Proper integration of a hydraulic drum brake requires attention to mounting dimensions, arm length, and clearance. Below are selected dimensional parameters for the TYW-300 model:

- Mounting Thread: M10x1

- Drum Diameter: 300 mm

- Overall Height (H): 330 mm

- Base Width (B): 125 mm

- Arm Length (A): 330 mm

- Weight: 40 kg

These dimensions are consistent with standard industrial brake configurations, allowing for retrofitting or replacement in existing systems. Engineers should verify compatibility with shaft diameters, drum widths, and hydraulic line connections during the design phase.

4. Selection Criteria Based on Use Case

When selecting a hydraulic drum brake, the following factors should be evaluated:

- Braking Torque Requirements: Match the rated torque to the maximum load and deceleration needs of the system. For example, TYW-400 (600–800 Nm) is suitable for mid-range crane systems, while TYW-500 (1400 Nm) is better suited for large winches or hoists.

- Hydraulic System Compatibility: Ensure the available hydraulic pressure matches the brake’s operating range. TYW-500’s 2.0 MPa requirement may be advantageous in systems with lower pressure capacity.

- Installation Space: Consider the brake’s height, width, and mounting hole specifications. TYW-315 offers a compact footprint with a 315 mm drum diameter and 42 kg weight.

- Maintenance Access: The TYW series is designed with accessible components, but installation orientation and surrounding equipment should allow for routine inspection and pad replacement.

5. Common Search Intent and Buyer Considerations

Based on keyword analysis, users searching for “hydraulic drum brake for crane,” “industrial brake system specifications,” or “TYW series brake dimensions” are typically:

- Engineers seeking technical data for system design or upgrade

- Procurement managers comparing models for cost-performance optimization

- Maintenance teams looking for compatible replacements with minimal downtime

To meet these needs, product pages and documentation should include:

- Detailed dimensional drawings (2D/3D CAD)

- Hydraulic connection diagrams

- Torque-pressure performance curves

- Installation and maintenance manuals

- Cross-reference tables for legacy brake models

6. Conclusion

The TYW Series Hydraulic Drum Brakes offer a range of torque capacities and installation options suitable for a wide spectrum of industrial applications. By focusing on verified technical data and real-world integration factors, this series supports informed decision-making for engineers and buyers alike.

For full technical documentation, CAD files, or application-specific consultation, contact us or authorized distributor.