In the world of heavy industrial machinery, a simple power outage can be catastrophic. When a crane is holding a multi-ton load, a wind turbine is facing gale-force winds, or a mine hoist is carrying personnel, the critical question isn’t if the brake will work, but what happens when the power to control it is suddenly lost. This is where the fail-safe brake system becomes the single most important safety feature on your equipment.

This comprehensive guide will explain the technology behind the fail-safe brake, how it works, its critical applications, and why it is the non-negotiable standard for any application where failure is not an option.

The Definition: What is a Spring-Applied Fail-Safe Brake?

A fail-safe brake, also known as a power-off brake or spring-applied brake, is an industrial safety device designed to be fully engaged in its natural, unpowered state. Think of it as a light switch that is “ON” by default. You must apply energy to turn it “OFF.”

Similarly, a fail-safe brake is always “ON” (braking) until power is actively supplied to release it and allow motion. If that power is cut—whether intentionally, due to a component failure, or a site-wide blackout—the brake instantly and automatically reverts to its engaged state, securing the load without needing any external command.

How Fail-Safe Brakes Work: The Spring-Applied, Power-Released Principle

The genius of the fail-safe brake lies in its use of reliable mechanical force for braking and external power for release. This simple, robust design is the foundation of its safety.

1. The Applied State (Default = Braking)

Inside every fail-safe brake is a set of powerful, pre-loaded mechanical springs. These springs constantly exert force to clamp the brake pads onto the disc or the shoes against the drum. This mechanical force is reliable, consistent, and requires zero external power to maintain the braking torque. This is the brake’s default, safe state.

2. The Released State (Powered = Motion)

To allow the machine to operate, an external power source is used to work against these springs, compressing them and pulling the braking surfaces apart. This “releases” the brake, allowing the shaft to rotate freely. The moment this external power is removed, the stored energy in the springs is instantly unleashed, engaging the fail-safe brake with full force.

Types of Fail-Safe Brake Release Mechanisms

The “power” used to release the brake can come from several sources, each suited to different industrial applications and environments.

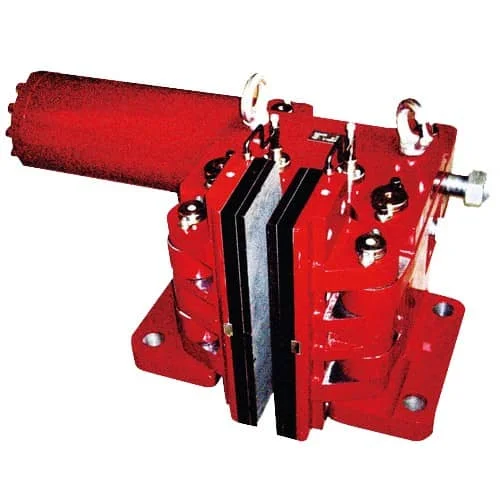

Hydraulic Fail-Safe Brakes

A hydraulic cylinder generates immense force to compress the springs, making this method ideal for very high-torque applications requiring massive braking power, such as large winches and mine hoists.

- Typical Products: Our SH Series Hydraulic Fail-Safe Disc Brakes are a prime example used in wind turbines and marine applications.

Pneumatic Fail-Safe Brakes

Similar to hydraulic, this method uses compressed air to release the brake. It’s a clean, fast-acting, and often readily available power source in many industrial facilities.

- Typical Products: The SP Series Pneumatic Fail-Safe Brakes offer reliable performance for conveyors and tensioning systems.

Electromagnetic Fail-Safe Brakes

An electric coil creates a powerful magnetic field to pull back an armature plate, compressing the springs and releasing the brake disc. This all-electric solution offers very fast response times for dynamic applications.

- Typical Products: SE Series Electromagnetic Fail-Safe Brakes are commonly found on smaller hoists, robotics, and motor brake applications.

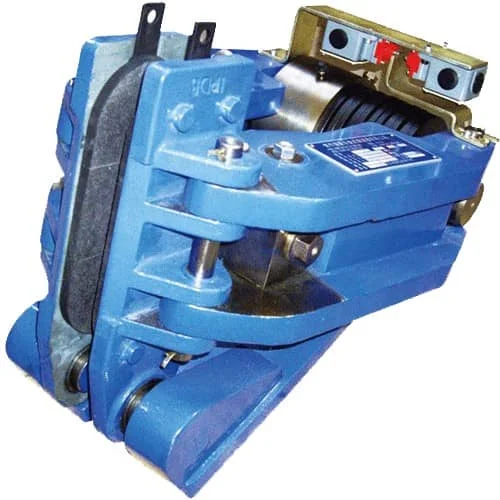

Electro-Hydraulic Fail-Safe Brakes

This is a self-contained unit that combines an electric motor, a centrifugal pump, and a hydraulic cylinder (known as a thruster). The motor drives the pump, which generates hydraulic pressure to release the brake. It expertly combines the high force of hydraulics with the convenience of an electrical connection.

- Typical Products: Our workhorse YWZ Series Electro-Hydraulic Drum Brakes use this proven and highly reliable fail-safe brake method on cranes worldwide.

Real-World Fail-Safe Brake Applications (Where They Are Essential)

The need for this technology becomes crystal clear when you consider the high stakes of these common industrial scenarios.

- Crane & Hoist Operations: A power loss during a lift could cause a suspended load to free-fall. The instant power is lost, the fail-safe hoist brake engages, locking the load securely in place.

- Wind Turbine Safety: During an overspeed event or for maintenance, the massive rotor must be stopped and held securely. Hydraulic fail-safe rotor and yaw brakes engage to stop the turbine and hold it against powerful wind loads.

- Mining & Downhill Conveyors: A loaded downhill conveyor can run away in reverse if power is lost. The fail-safe brake acts as a “holdback,” automatically preventing the belt from moving.

- Elevators & Escalators: Passenger safety is paramount. The emergency brake on an elevator is a classic example of a fail-safe system that engages during a power failure to prevent the cabin from falling.

Service Brakes vs. Fail-Safe Brakes: Understanding the Difference

It’s important to distinguish between two primary brake functions. A Service Brake is used for dynamic stopping during normal operation (power-on braking). A Fail-Safe Brake is primarily a static holding or emergency brake (power-off braking). Many systems use both: a service brake for routine stops and a fail-safe brake for parking, holding, and emergency E-stops.

Frequently Asked Questions about Fail-Safe Brakes

What is the difference between fail-safe and fail-secure?

These terms are opposites. Fail-safe means the device reverts to a safe state when power is lost (e.g., a brake engages). Fail-secure means the device remains in its last state or becomes secured when power is lost (e.g., an electric door lock remains locked).

How do you test a fail-safe brake?

Testing involves safely cutting power to the brake’s release mechanism while the machine is in a controlled state (e.g., holding a test load just off the ground) to verify that it engages correctly and holds the load without slipping. Always follow the manufacturer’s specific testing procedures.

Can a fail-safe brake be used for dynamic stopping?

Yes, but they must be designed for it. While primarily used for static holding, many fail-safe brakes are also rated for a certain number of emergency dynamic stops. Using a holding brake for frequent dynamic stops can cause premature wear and overheating if it’s not designed for that duty cycle.

Conclusion: A Fail-Safe Brake is a Safety Philosophy

A fail-safe brake is more than a component; it’s a foundational element of responsible machine design. By defaulting to a safe, braked state, it eliminates the immense risk of power-related failures turning into disasters.

When selecting a brake for any critical industrial application, the first question should always be: “Is the braking system truly fail-safe?” For operations involving heavy loads, high speeds, or protecting personnel, the answer must be yes.