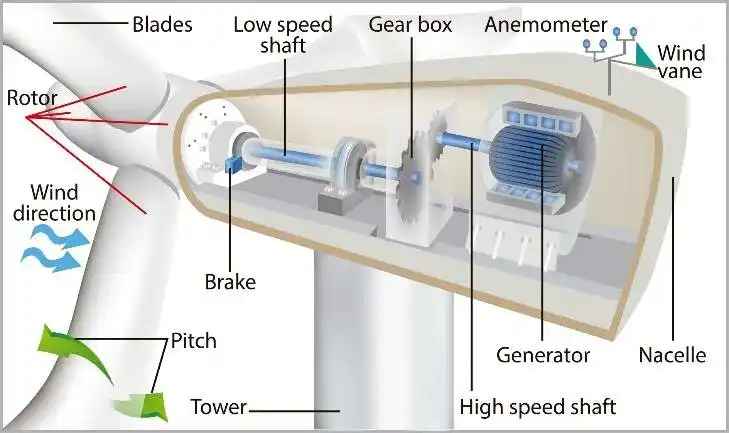

A modern wind turbine is a marvel of engineering, designed to harness the wind’s power with precision and efficiency. But just as important as capturing energy is the ability to control it and, when necessary, bring the massive structure to a safe, complete stop. This control is achieved through a sophisticated interplay of three distinct systems: Yaw, Pitch, and Rotor braking.

While they all involve “braking” in some sense, they serve very different functions—much like the steering, service brakes, and emergency handbrake on a car. Understanding the role of each is key to appreciating the safety and operational strategy of a wind turbine.

1. The Yaw System: Steering the Turbine

Purpose: The yaw system’s job is not to stop the blades, but to orient the entire nacelle (the main housing) so that the rotor is always facing directly into the wind. This maximizes energy capture and minimizes harmful, off-axis loads on the structure.

How it Works: The nacelle sits on a large ring bearing at the top of the tower. A series of electric or hydraulic motors, the “yaw drives,” turn the nacelle. The Yaw Brakes are a set of powerful, spring-applied, hydraulically released caliper brakes that clamp onto a large yaw disc or ring.

- During Operation: The yaw brakes are used to hold the nacelle firmly in position once it’s aligned with the wind. They are frequently applied and released in a “slip-brake” mode to allow for small, controlled adjustments and to dampen structural vibrations.

- Function: Think of it as the “parking brake” for the turbine’s direction.

The Technology: Yaw brakes must provide extremely high holding torque and be incredibly reliable. This is why spring-applied, hydraulic caliper brakes like our SH Series Fail-Safe Brakes

2. Pitch Control: The Primary Method of Speed Control & Braking

Purpose: The pitch control system is the turbine’s primary and most elegant method for controlling rotor speed and power output. It is also the first line of defense in an emergency stop.

How it Works: Each blade is attached to the hub via a bearing that allows it to rotate along its long axis. This rotation is called “pitching.” A hydraulic or electric pitch control system can instantly change the angle of attack of all three blades simultaneously.

- During Operation: The system makes micro-adjustments to the blade pitch to maintain a constant rotor speed and power output once the wind speed exceeds the turbine’s rated limit.

- During Shutdown: To stop the turbine, the blades are “feathered”—pitched 90 degrees out of the wind. This immediately eliminates the aerodynamic lift, causing the rotor to slow down dramatically and safely. This is the primary braking method for both normal and emergency shutdowns.

Function: This is the equivalent of the main service brakes on a car, using aerodynamics instead of friction.

3. The Rotor Brake: The Ultimate Failsafe

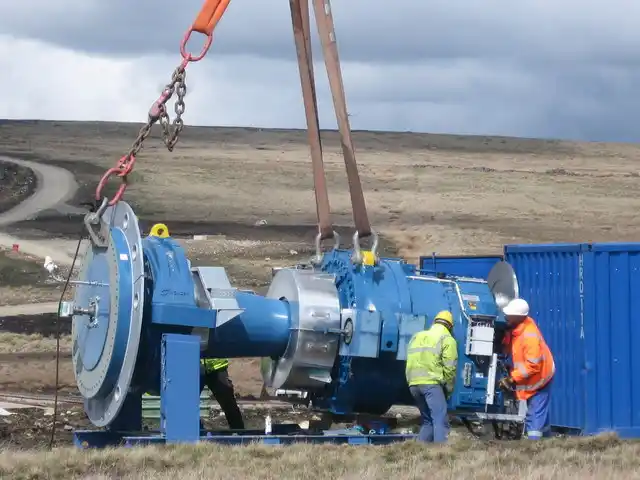

Purpose: If pitch control is the service brake, the Rotor Brake is the ultimate emergency handbrake and parking lock. Its primary roles are to bring the rotor to a complete stop after it has been slowed by the pitching system and to lock it securely for maintenance.

How it Works: The rotor brake is a massive disc brake, very similar in principle to a yaw brake. It is typically located on the high-speed shaft of the gearbox (between the gearbox and the generator).

- During Emergency Stop: After the blades are feathered, the rotor brake engages to bring the slowly turning rotor to a complete standstill (0 RPM). It is NOT designed to stop the rotor from full speed on its own, as the energy involved would be immense and could damage the drivetrain.

- During Maintenance: The rotor brake is engaged as a mechanical lock to prevent the rotor from moving while technicians are working inside the hub or on the blades. This is a critical safety function.

The Technology: Like the yaw brake, the rotor brake must be absolutely reliable. It is always a spring-applied, fail-safe design. High-torque hydraulic caliper brakes, such as our SDBH_I Series Hydraulic Brakes

A Symphony of Safety

The yaw, pitch, and rotor systems work in concert to ensure a wind turbine operates efficiently and, above all, safely.

- The Yaw System steers and holds direction.

- The Pitch System controls speed and performs the primary aerodynamic braking.

- The Rotor Brake provides the final, secure mechanical lock for parking and emergencies.

Understanding this relationship makes it clear why robust, reliable, and fail-safe braking technology is not just an accessory but a cornerstone of modern wind energy.