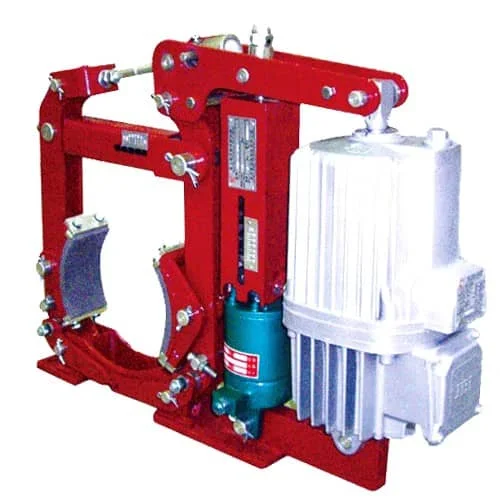

Technical Overview of YW-E Two-Stage Electric Hydraulic Drum Brake for Heavy-Duty Industrial Applications

In industrial environments where precise and reliable braking is essential, the YW-E series two-stage electric hydraulic drum brake offers a solution engineered for demanding applications such as crane travel mechanisms and conveyor systems. This article presents a detailed technical examination of the YW-E brake, emphasizing its design features, performance parameters, and application relevance, supported by specific data to aid engineers and procurement specialists in informed decision-making.

Dual-Stage Braking Principle and Its Industrial Relevance

The YW-E brake employs a dual-stage braking system, a critical feature for heavy machinery requiring controlled stopping power. The first stage provides immediate braking force, securing the load quickly, while the second stage delivers adjustable braking time through a unidirectional flow control valve. This design allows for smooth deceleration, preventing mechanical shocks that can damage equipment or compromise safety.

Technical Specifications and Performance Data

The YW-E series covers a range of models with varying braking torques from 35 Nm to 1260 Nm, enabling compatibility across machinery with different load requirements. Below is a summary of key models and their parameters:

- YW-E200 series (e.g., YW-E200/E23, YW-E200/E30, YW-E200/E50) delivers braking torques from 35 to 250 Nm. These models suit lighter cranes and conveyor belts, featuring drum diameters around 200 mm and weights ranging between 42 and 56 kg.

- YW-E250/E50 increases torque capacity up to 315 Nm, offering a mid-range solution with a drum diameter of 250 mm and weight of approximately 90 kg.

- YW-E315 series (e.g., YW-E315/E50, YW-E315/E80) supports braking torques from 200 to 630 Nm, with drum diameters around 315 mm and weights between 123 and 126 kg. These are appropriate for medium to heavy-duty industrial cranes.

- YW-E400/E80 provides up to 630 Nm braking torque with a 400 mm drum diameter and 150 kg weight, suited for large-scale equipment requiring substantial stopping force.

The brake’s modular design ensures each model can be matched with corresponding electric hydraulic thrusters (Ed23/5, Ed30/5, Ed50/6, Ed80/6), ensuring optimal actuation force and control precision. This compatibility is integral to system integration and maintenance efficiency.

Compliance and Installation

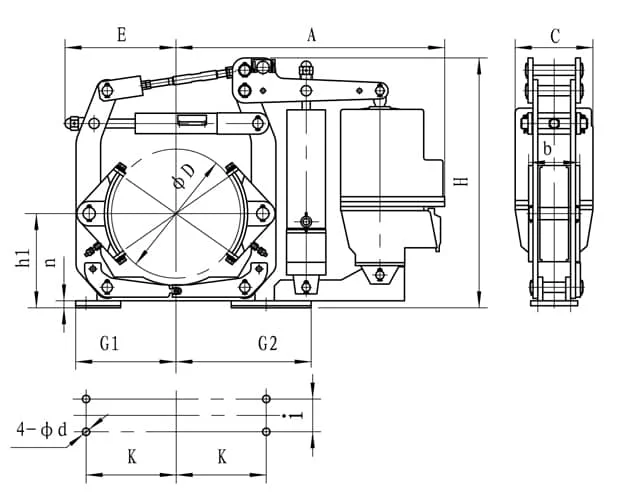

The YW-E brake conforms to DIN 15435 and JB/T 7021-2006 standards, ensuring dimensional compatibility and reliability in international applications. Installation dimensions such as drum diameter, shoe width, and mounting hole spacing are standardized, facilitating replacement and retrofit scenarios without extensive modifications.

Application Suitability and Customer Considerations

Customers searching for two-stage electric hydraulic drum brakes typically prioritize:

- Safety and Reliability: The dual-stage braking mechanism with adjustable second-stage timing addresses the need for controlled deceleration, reducing wear and preventing abrupt stops.

- Torque Range and Scalability: The availability of models spanning 35 Nm to 1260 Nm torque supports diverse industrial needs, from light conveyors to heavy crane travel drives.

- Standard Compliance: Conformance to DIN and JB/T standards provides assurance of quality and interoperability.

- Ease of Integration: Matching thrusters and standardized mounting allow for straightforward installation and reduced downtime.

- Application Specificity: The YW-E series is tailored for crane long-travel mechanisms and belt conveyor systems, reflecting the typical search intent of customers engaged in port operations, mining, steel manufacturing, and bulk material handling.

Conclusion

The YW-E two-stage electric hydraulic drum brake is a technically sound choice for industrial braking systems requiring precise control, robust performance, and compliance with international standards. Its range of models and matched thrusters offer scalable solutions adaptable to various load profiles and operational environments. By focusing on reliable dual-stage braking and adjustable performance parameters, the YW-E series aligns closely with the critical needs identified by international customers searching for advanced drum brake solutions.

| Model | braking torque (Nm) | D | A | E | H | h1 | G1 | G2 | i | k | n | d | b | C | Weight (kg) | |||

| Brakes | Matching Thruster | Step 1 | Step 2 | Total braking torque | ||||||||||||||

| YW-E200/E23 | Ed23/5 | 35-80 | 80-150 | 230 | 200 | 490 | 190 | 520 | 160 | 165 | 265 | 55 | 145 | 10 | 14 | 70 | 160 | 42 |

| YW-E200/E30 | Ed30/5 | 80-160 | 80-155 | 315 | 200 | 500 | 190 | 520 | 160 | 165 | 265 | 55 | 145 | 10 | 14 | 70 | 160 | 46 |

| YW-E200/E50 | Ed50/6 | 120-250 | 120-250 | 500 | 200 | 535 | 190 | 560 | 160 | 165 | 265 | 55 | 145 | 10 | 14 | 70 | 190 | 56 |

| YW-E250/E50 | Ed50/6 | 160-315 | 160-315 | 630 | 250 | 580 | 225 | 590 | 190 | 200 | 300 | 65 | 180 | 12 | 18 | 90 | 190 | 90 |

| YW-E315/E50 | Ed50/6 | 200-400 | 200-400 | 800 | 315 | 655 | 270 | 620 | 230 | 245 | 330 | 80 | 220 | 12 | 18 | 110 | 190 | 123 |

| YW-E315/E80 | Ed80/6 | 315-630 | 315-630 | 1260 | 315 | 655 | 270 | 620 | 230 | 245 | 330 | 80 | 220 | 12 | 18 | 110 | 190 | 126 |

| YW-E400/E80 | Ed80/6 | 315-630 | 315-630 | 1260 | 400 | 740 | 318 | 720 | 280 | 310 | 420 | 100 | 270 | 14 | 22 | 140 | 190 | 150 |