Precision Engineering for Industrial Applications

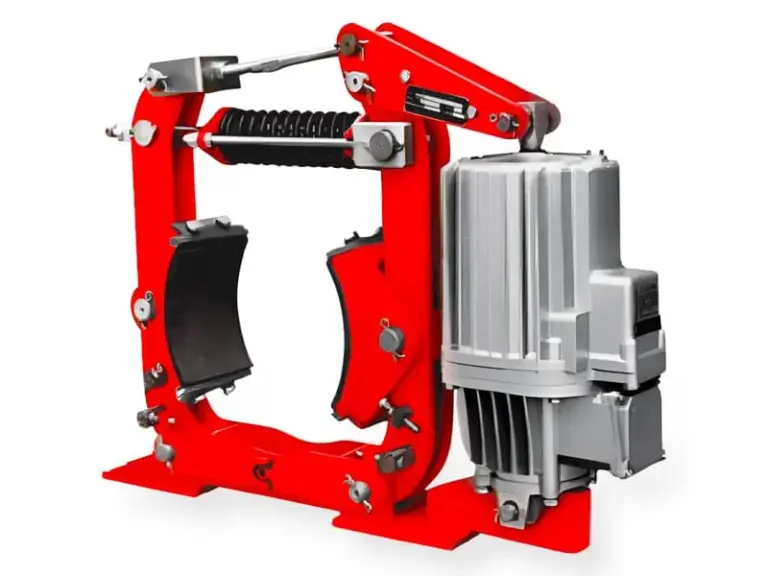

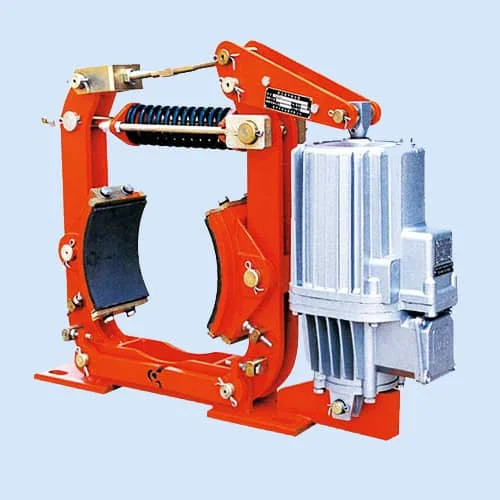

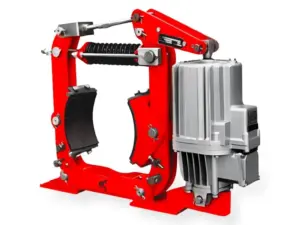

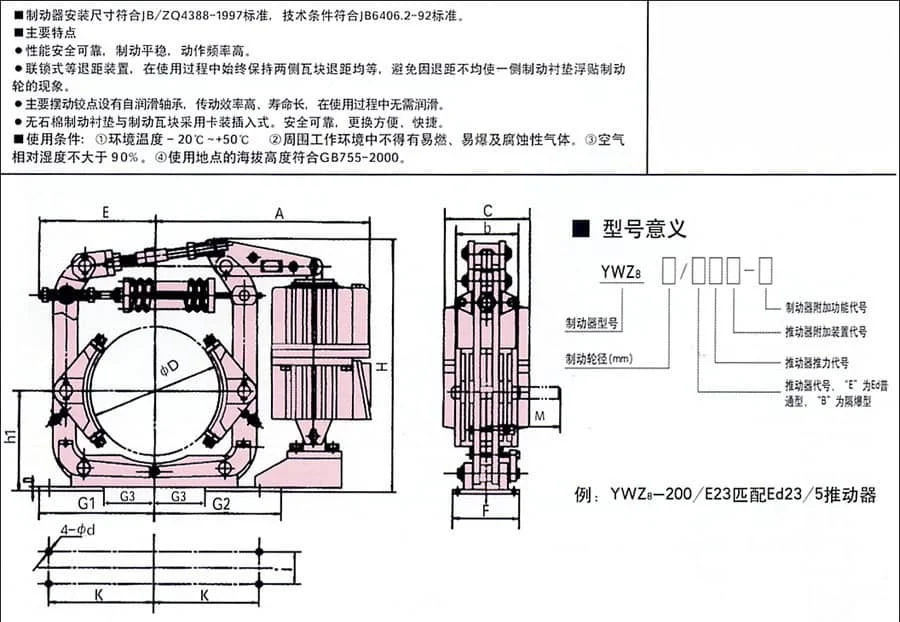

The YW-P Series Electric Hydraulic Drum Brakes are engineered for demanding industrial environments, delivering robust, reliable performance tailored to a variety of applications. Available in multiple models—YW-P160, YW-P200, YW-P250, YW-P300, YW-P315, YW-P400, YW-P500, and YW-P630—each brake is designed to meet specific torque requirements, ensuring optimal functionality across diverse machinery.

Key Features and Technical Specifications

- Brake Torque Ratings: Ranging from 160 Nm (YW-P160) to 630 Nm (YW-P630), each model accommodates varying load capacities, making it suitable for heavy-duty applications.

- Operating Pressure: Configured for an operational range of 10-20 MPa, providing effective and responsive braking performance under high-stress conditions.

- Weight and Dimensions: Each model is designed with a compact and lightweight structure, facilitating easy integration into existing systems while maintaining structural integrity.

Model Breakdown

- YW-P160: Ideal for lighter machinery and applications where space is limited, providing dependable performance with a torque rating of 160 Nm.

- YW-P200: Suitable for moderate loads and versatile applications, delivering a reliable 200 Nm of braking power.

- YW-P250: This model offers enhanced torque capacity, making it perfect for applications requiring robust braking in dynamic environments.

- YW-P300: A balanced option for medium to heavy-duty operations, providing 300 Nm of torque while ensuring smooth performance.

- YW-P315: Designed for slightly heavier machinery, this model combines power with efficiency, making it suitable for demanding tasks.

- YW-P400: With a torque rating of 400 Nm, this model is ideal for industrial applications where safety and reliability are paramount.

- YW-P500: Engineered for high-load scenarios, delivering exceptional braking performance while maintaining ease of operation.

- YW-P630: The most powerful in the series, providing up to 630 Nm of torque, perfect for heavy machinery and critical applications.

Performance and Durability

Constructed using high-strength, corrosion-resistant materials, the YW-P Series is built to withstand the rigors of industrial environments. The self-lubricating design minimizes friction wear, ensuring a longer lifespan and reduced maintenance frequency. This durability translates into a lower total cost of ownership for your operations, making it a smart investment.

Safety Mechanisms

Safety is integral to the design of the YW-P Series. Each model incorporates critical safety features, such as:

- Automatic Fault Detection: Monitors system performance in real-time, alerting operators to potential issues before they escalate.

- Overload Protection: Engages automatically to prevent damage during excessive loads, ensuring the safety of both the brake and the equipment it serves.

These features help maintain safe and efficient operations, adhering to industry standards for safety and reliability.

Versatile Applications

The YW-P Series is suitable for a wide range of applications, including:

- Hoisting Equipment: Models like the YW-P400 and YW-P500 are ideal for cranes and lifts, providing reliable stopping power under heavy loads.

- Mining Machinery: The robust design of the YW-P315 and YW-P630 makes them suitable for the harsh conditions of mining operations.

- Conveyor Systems: Models such as the YW-P200 and YW-P250 offer smooth and controlled braking for material handling processes, enhancing operational efficiency.

Actuator Compatibility

To ensure precise control and operation, the YW-P Series is compatible with various actuators, including:

- Ed23/5: A compact actuator that pairs well with lighter models like YW-P160 and YW-P200.

- Ed30/5: Offers reliable performance for medium-duty applications, compatible with YW-P250 and YW-P300.

- Ed50/6: Designed for heavier applications, ideal for YW-P400 and YW-P500.

- Ed121/6, Ed201/6, and Ed301/6: Provide enhanced functionality and are suitable for the higher torque models like YW-P500 and YW-P630.

These actuator options allow for flexibility in system design and tailored solutions for specific operational requirements.

Installation and Customization

The YW-P Series is designed for straightforward installation, featuring user-friendly guides and adjustable components that simplify the setup process. This design reduces installation time and operational downtime, enabling your business to maintain its competitive edge. Additionally, customization options are available to ensure the brake system meets your specific operational needs.

Environmental Considerations

With a focus on sustainability, the YW-P Series is constructed using recyclable materials and designed for energy efficiency. This commitment aligns with modern industry standards for environmental responsibility, allowing your business to achieve operational goals while minimizing its ecological footprint.

Comprehensive Support

Choosing the YW-P Series means you gain access to extensive technical support and after-sales service. Our dedicated team is available to assist with installation, troubleshooting, and ongoing maintenance, ensuring that your braking system operates at peak efficiency throughout its lifespan.

Conclusion

The YW-P Series Electric Hydraulic Drum Brake is engineered to meet the rigorous demands of industrial applications. With its wide range of models, robust performance, and commitment to safety, it is a critical component for enhancing the efficiency and reliability of your machinery.

For more information on how the YW-P Series can be integrated into your operations, please contact us to discuss your specific needs and receive tailored solutions.