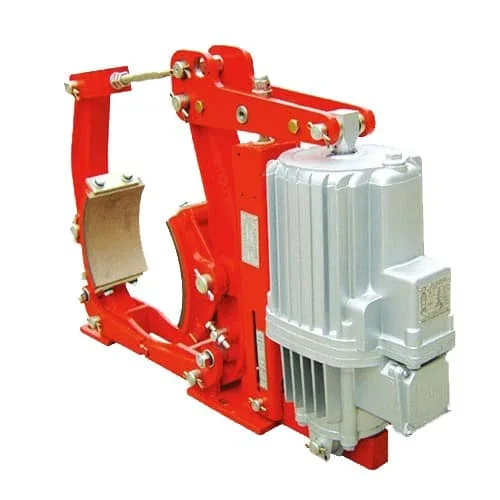

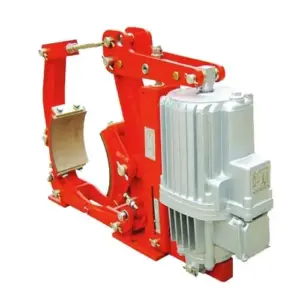

Product Overview

The YW Series Electro-Hydraulic Drum Brakes are expertly designed for efficient deceleration and reliable parking brake mechanisms. These brakes are widely used across various sectors, including heavy machinery, port handling, metallurgy, mining, and construction equipment. Their robust design and compliance with international standards make them a top choice for new machine designs and replacements for older brake models.

Key Features

- Standard Compliant:

- The YW and YWB series meet JB/T6406-2006 standards for dimensions and technical requirements, and their braking torque parameters comply with DIN15435 standards.

- Additional series like YWZ5, YWZE, YWZ6, YWZF, YWZ2, YWZB, YWZ4, and YWZD conform to standards such as GB6333-86, DIN15430, and JB/ZQ4388-86.

- Advanced Technology:

- Patented interlocking shoe clearance balancing device and automatic shoe aligning device ensure equal clearance on both sides, eliminating the need for adjustments and preventing uneven wear.

- Self-lubricating bearings at pivotal points increase efficiency and longevity without the need for lubrication.

- Ease of Use:

- The brakes feature a card whole piece shaping structure for easy and quick replacement of brake linings, available in various materials like half-metal (non-asbestos) and soft substances.

- An integrated surveyor’s rod simplifies reading of braking torque values, removing the need for complex measurements.

Applications and Compatibility

- Versatile Applications: These brakes are ideal for new designs and as replacements for older systems, including the YWZ, JCZ, JWZ, and TJ2 series.

- Operating Conditions: Suitable for ambient temperatures ranging from -25°C to +50°C and relative humidity up to 90%. They support voltages of 380-400V at 50Hz and 440-460V at 60Hz, with both intermittent and continuous operating duties.

Additional Features

- Optional hand release levers and open/close limit-switches provide operational flexibility and safety.

- Self-compensating devices for brake pad wear ensure consistent performance and longevity.

- Compatible with thrusters featuring descending delay valves for controlled braking in specific applications.

Installation and Ordering

The YW Series offers a variety of installation configurations to suit different mechanical requirements. When ordering, specify additional options like corrosion protection and special requirements to tailor the brakes to your specific needs.

Conclusion

The YW Series Electro-Hydraulic Drum Brakes offer a reliable, efficient, and flexible solution for braking needs across various industries. With their adherence to international standards and innovative features, they ensure high performance and safety in demanding applications.

This product overview provides a comprehensive understanding of the YW Series, making it easier for engineers and procurement professionals to choose the right solution for their machinery needs.