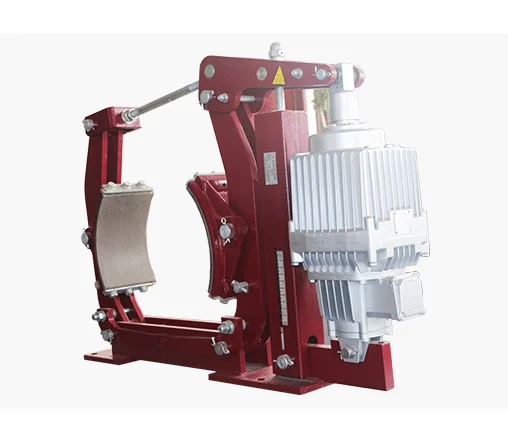

Explore the YWZ10 Series Electric Hydraulic Drum Brakes: Performance and Dependability for Contemporary Industry

Performance Redefined

In the realm of industrial machinery, reliability and efficiency are crucial. The YWZ10 series electric hydraulic drum brakes establish a new benchmark in performance, delivering unparalleled quality and innovation for a variety of industrial applications. Crafted with precision and designed to fulfill the rigorous demands of modern industry, these brakes represent the perfect solution for ensuring smooth and safe operations.

Benefits of YWZ10 Series Electric Hydraulic Drum Brakes

The YWZ10 series distinguishes itself in the marketplace due to its exceptional design and functionality. A significant advantage is its adherence to the GB6333-86 and JB/T6406-2006 standards, guaranteeing high safety and performance standards. These brakes are suitable for environments with ambient temperatures ranging from -20℃ to 50℃ and can function effectively in relative humidity levels up to 90%. With options for anti-corrosion models, they are ideal for settings where flammable, explosive, or corrosive gases may be present.

Key Features That Make a Difference

The YWZ10 series comes equipped with a variety of features that enhance its functionality and user experience:

Enhanced Safety Features: With optional manual devices and protective covers, these brakes provide additional safety measures, ensuring peace of mind during operations.

Versatile Functionality: Designed to accommodate various installation types, the YWZ10 series integrates seamlessly into different machinery configurations, offering flexibility and adaptability.

Robust Construction: Engineered to endure harsh conditions, these brakes deliver reliable performance without the need for frequent maintenance, thereby reducing downtime and costs.

Addressing Challenges in the Industry

Industrial machinery frequently encounters problems like wear and tear, variable performance, and elevated maintenance expenses. The YWZ10 series tackles these challenges directly. Its robust construction lessens wear, while its efficient design decreases the necessity for regular maintenance, thus conserving both time and financial resources. Additionally, the series provides a variety of models, guaranteeing an appropriate match for particular needs and operational demands.

Why Opt for YWZ10 Series Brakes?

Selecting the YWZ10 series signifies a commitment to quality and dependability. These brakes not only improve operational efficiency but also enhance safety in the workplace. Whether you require brakes for cranes, conveyors, or other heavy-duty machinery, the YWZ10 series offers outstanding performance and durability.

In summary, the YWZ10 series electric hydraulic drum brakes exemplify innovation and excellence in industrial braking solutions. With their cutting-edge features and sturdy design, they are set to become essential for the efficient and safe functioning of industrial equipment. Embrace the future of braking technology with the YWZ10 series and witness the enhancement in quality and reliability.

| Model | Torque (Nm) | Setback | A | b | C | D | d | E | F | G1 | G2 | H | Hmax | h1 | i | K | n | weightkg | |

| Brakes | Drive | ||||||||||||||||||

| YWZ10-200/E23 | Ed23/5 | 80-130 | 1 | 445 | 80 | 160 | 200 | 14 | 210 | 100 | 230 | 230 | 415 | 450 | 160 | 55 | 145 | 12 | 55 |

| YWZ10-200/E30 | Ed30/5 | 80-200 | 445 | 480 | 59 | ||||||||||||||

| YWZ10-250/E23 | Ed23/5 | 100-170 | 1 | 550 | 100 | 160 | 250 | 18 | 260 | 120 | 260 | 260 | 495 | 530 | 190 | 65 | 180 | 14 | 69 |

| YWZ10-250/E30 | Ed30/5 | 100-240 | 72 | ||||||||||||||||

| YWZ10-250/E50 | Ed50/6 | 220-500 | 190 | 515 | 555 | 73 | |||||||||||||

| YWZ10-315/E30 | Ed30/5 | 230-280 | 1.2 | 600 | 125 | 160 | 315 | 18 | 350 | 130 | 320 | 320 | 555 | 595 | 225 | 80 | 220 | 16 | 105 |

| YWZ10-315/E50 | Ed50/6 | 430-550 | 190 | 600 | 108 | ||||||||||||||

| YWZ10-315/E80 | Ed80/6 | 430-1050 | 110 | ||||||||||||||||

| YWZ10-400/E50 | Ed50/6 | 510-650 | 1.3 | 710 | 160 | 190 | 400 | 22 | 375 | 160 | 375 | 375 | 675 | 675 | 280 | 100 | 270 | 18 | 175 |

| YWZ10-400/E80 | Ed80/6 | 510-1100 | 180 | ||||||||||||||||

| YWZ10-400/E121 | Ed121/6 | 820-1800 | 240 | 758 | 800 | 197 | |||||||||||||

| YWZ10-500/E80 | Ed80/6 | 970-1200 | 1.5 | 760 | 200 | 190 | 500 | 22 | 440 | 190 | 440 | 440 | 790 | 790 | 335 | 130 | 325 | 20 | 200 |

| YWZ10-500/E121 | Ed121/6 | 970-2000 | 770 | 815 | 213 | ||||||||||||||

| YWZ10-500/E201 | Ed201/6 | 1500-3200 | 240 | 213 | |||||||||||||||

| YWZ10-630/E121 | Ed121/6 | 1200-2100 | 1.7 | 830 | 250 | 240 | 630 | 27 | 560 | 240 | 540 | 540 | 970 | 1015 | 425 | 170 | 400 | 28 | 434 |

| YWZ10-630/E201 | Ed201/6 | 2000-3600 | 434 | ||||||||||||||||

| YWZ10-630/E301 | Ed301/6 | 2800-5300 | 435 | ||||||||||||||||

| YWZ10-630/E301/12 | Ed301/12 | 3500-7000 | 2 | 950 | 1045 | 444 | |||||||||||||

| YWZ10-710/E201 | Ed201/6 | 2300-4000 | 18 | 915 | 280 | 240 | 710 | 27 | 650 | 260 | 610 | 610 | 1060 | 1105 | 475 | 190 | 450 | 28 | 624 |

| YWZ10-710/E301 | Ed301/6 | 3100-6000 | 624 | ||||||||||||||||

| YWZ10-710/E301/12 | Ed301/12 | 4000-8000 | 2 | 1070 | 1135 | 684 | |||||||||||||

| YWZ10-800/E301/12 | Ed301/12 | 5300-9000 | 2 | 1130 | 320 | 240 | 800 | 27 | 700 | 300 | 680 | 680 | 1300 | 1300 | 530 | 210 | 520 | 28 | 700 |

| Model | Drive | Torque (Nm) | Setback | A | B | BO | B1 | B2 | C1 | C2 | C3 | D | d | d1 | E | F | f | f1 | G | G1 | H | H0 | h1 | h2 | i | K | L | L1 | L2 | m | n | n1 | Q | Weight kg |

| YWZ10-F2 00/23-S | Ed23/5 | 80-130 | 1 | 720 | 230 | 238 | 180 | 230 | 160 | 220 | 200 | 14 | 106 | 260 | 250 | 80 | 564 | 460 | 665 | 650 | 160 | 145 | 55 | 145 | 840 | 828 | 820 | 450 | 10 | 5 | 55 | 60 | ||

| YWZ10-F2 00/30-S | Ed30/5 | 80-200 | 65 | |||||||||||||||||||||||||||||||

| YWZ10-F250/23-S | Ed23/5 | 100-170 | 1.2 | 750 | 260 | 268 | 220 | 260 | 200 | 250 | 250 | 18 | 126 | 305 | 280 | 100 | 653 | 560 | 744 | 730 | 190 | 176 | 65 | 180 | 970 | 956 | 948 | 550 | 10 | 4 | 55 | 85 | ||

| YWZ10-F250/30-S | Ed30/5 | 100-240 | 90 | |||||||||||||||||||||||||||||||

| YWZ10-F250/50-S | Ed50/6 | 220-500 | 102 | |||||||||||||||||||||||||||||||

| YWZ10-F315/30-S | Ed30/5 | 230-280 | 1.2 | 830 | 260 | 268 | 200 | 280 | 315 | 18 | 166 | 380 | 280 | 150 | 730 | 775 | 760 | 225 | 209 | 80 | 220 | 1120 | 1108 | 1100 | 12 | 4 | 55 | 110 | ||||||

| YWZ10-F315/50-S | Ed50/6 | 430-550 | 120 | |||||||||||||||||||||||||||||||

| YWZ10-F315/80-S | Ed80/6 | 430-1050 | 127 | |||||||||||||||||||||||||||||||

| YWZ10-F400/50-S | Ed50/6 | 510-630 | 1.5 | 930 | 280 | 288 | 180 | 300 | 400 | 22 | 186 | 440 | 300 | 180 | 821 | 818 | 800 | 280 | 262 | 100 | 270 | 1270 | 1260 | 1251 | 14 | 4 | 70 | 170 | ||||||

| YWZ10-F400/80-S | Ed80/6 | 510-1000 | 170 | |||||||||||||||||||||||||||||||

| YWZ10-F400/121-S | Ed121/6 | 820-1800 | 968 | 950 | 60 | 205 | ||||||||||||||||||||||||||||

| YWZ10-F500/80-S | Ed80/6 | 970-1200 | 2 | 990 | 300 | 308 | 200 | 330 | 500 | 22 | 216 | 510 | 330 | 330 | 881 | 985 | 965 | 335 | 315 | 130 | 325 | 1400 | 1390 | 1381 | 16 | 4 | 60 | 250 | ||||||

| YWZ10-F500/121-S | Ed121/6 | 970-2000 | 275 | |||||||||||||||||||||||||||||||

| YWZ10-F500/201-S | Ed201/6 | 1500-3200 | 275 | |||||||||||||||||||||||||||||||

| YWZ10-F630/121-S | Ed121/6 | 1200-2100 | 2 | 1120 | 360 | 368 | 260 | 260 | 260 | 630 | 27 | 226 | 615 | 400 | 240 | 230 | 987 | 1128 | 1100 | 425 | 397 | 170 | 400 | 1615 | 1595 | 1587 | 20 | 74 | 390 | |||||

| YWZ10-F630/201-S | Ed201/6 | 2000-3600 | 390 | |||||||||||||||||||||||||||||||

| YWZ10-F630/301-S | Ed301/6 | 2800-5300 | 390 | |||||||||||||||||||||||||||||||

| YWZ10-F630/301/12-S | Ed301/12 | 3500-7000 | 1250 | 440 | 1196 | 1735 | 480 | |||||||||||||||||||||||||||

| YWZ10-F710/201-S | Ed201/6 | 2300-4000 | 2 | 1220 | 370 | 378 | 270 | 270 | 270 | 710 | 27 | 260 | 675 | 410 | 280 | 280 | 1092 | 1280 | 1180 | 475 | 447 | 190 | 450 | 1785 | 1760 | 1752 | 20 | 8 | 74 | 520 | ||||

| YWZ10-F710/301-S | Ed301/6 | 3100-6000 | 520 | |||||||||||||||||||||||||||||||

| YWZ10-F710/301/12-S | Ed301/12 | 4000-8000 | 1350 | 400 | 408 | 280 | 280 | 280 | 440 | 1227 | 1328 | 1300 | 1920 | 1895 | 1887 | 580 |