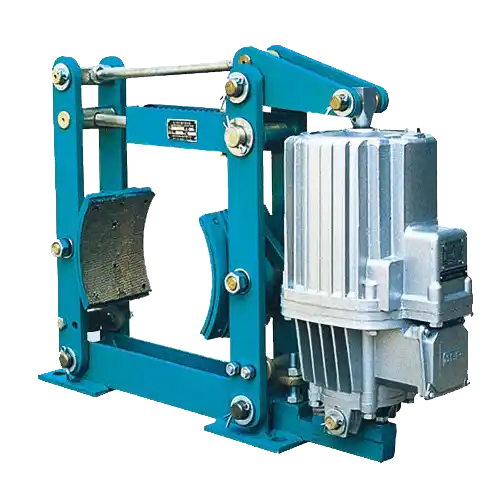

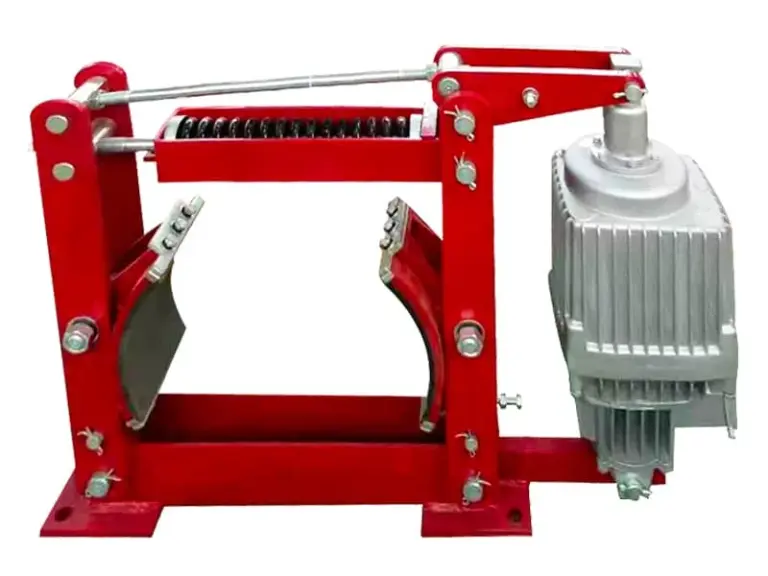

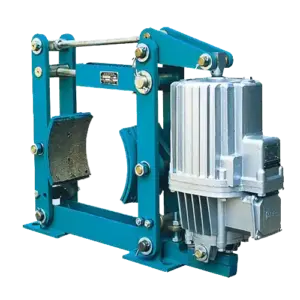

The YWZ4 series electric hydraulic drum brakes are advanced braking systems designed for industrial applications. These brakes are characterized by their compatibility with Ed and YT1 series pushers, providing flexibility and adaptability for various operational needs. Here, we will explore the advantages, application range, working principles, usage methods, and key specifications of these brakes, as detailed in the provided files.

Advantages

- High Efficiency and Reliability:

- The YWZ4 series brakes are equipped with self-lubricating bearings at the main swing hinge points, which enhance transmission efficiency and eliminate the need for lubrication during use. This reduces maintenance requirements and prolongs the lifespan of the brake system.

- Versatile Brake Pad Installation:

- Users can choose between riveted or inserted brake pad installation types, offering flexibility in maintenance and replacement procedures.

- Robust Design Standards:

- The brakes adhere to JB/ZQ4388-1997 installation size standards and JB/T6406-2006 technical requirements, ensuring reliability and compatibility with various industrial systems.

Application Range

These brakes are best suited for environments where reliable stopping power is crucial, such as in cranes, conveyors, and other heavy machinery used in industrial settings. Their specifications allow for use in environments with temperatures ranging from -20℃ to 50℃ and relative humidity up to 90%, making them ideal for a broad range of climates and operational conditions.

Key Specifications and Models

- YWZ4-100/E23 & YWZ4-100/E30:

- These models feature smaller dimensions, suitable for applications requiring moderate braking force. The Ed23/5 and Ed30/5 pushers provide torque values of 21Nm and 24Nm, respectively.

- Weight: 40kg (YWZ4-100/E23), 100kg (YWZ4-100/E30).

- YWZ4-400/E50:

- Designed for a wheel diameter of 400mm and paired with the YT1-90Z/8 pusher, this model offers a braking torque of 1000Nm, making it suitable for larger, more demanding applications.

- YWZ4-800/E301 & YWZ4-800/320:

- These high-capacity models are equipped with Ed301/12 and YT1-320Z/12 pushers, providing a torque of up to 12500Nm, ideal for heavy-duty operations.

- Weight: 885kg (YWZ4-800/320).

Working Principle

The YWZ4 series brakes operate through hydraulic pressure generated by the Ed or YT1 pushers, which actuate the braking mechanism. The hydraulic system ensures smooth and precise braking, essential for industrial applications where safety and performance are paramount.

Usage Method

To use the YWZ4 series brakes effectively, it is important to adhere to the provided specifications regarding environmental conditions and installation guidelines. Users should ensure:

- The installation aligns with the specified dimensions and technical standards.

- The surroundings are free from flammable, explosive, or corrosive gases unless using a corrosion-resistant model.

- Regular inspections are conducted to verify the integrity of the self-lubricating bearings and the condition of the brake pads.

Considerations

When selecting a brake model, it is crucial to consider the specific requirements of the application, such as the required braking torque and environmental conditions. Additionally, users should be aware that the structural dimensions and specifications may be subject to change, thus confirming details during the order process is recommended.

In summary, the YWZ4 series electric hydraulic drum brakes offer a robust, versatile solution for industrial braking needs, with a range of models and specifications to suit various applications. Their high efficiency, compliance with industry standards, and adaptability make them a preferred choice in many industrial sectors.