Application Range

The YWZ8 series electric-hydraulic drum brakes are widely used in various mechanical systems that require high braking torque and precise control. These brakes are ideal for heavy-duty applications across several industries. Below are some key examples of their application:

- Cranes and Hoists: For instance, the YWZ8-200/E23 model, with a braking torque of 135-200 Nm, is commonly used in industrial cranes and hoisting equipment to ensure smooth stopping and prevent overloads.

- Power Systems: In power plants, the YWZ8-300E30 model, which provides a braking torque of 200-320 Nm, is employed to brake generators and pumps.

- Mining Machinery: Models like the YWZ8-200/E23, which is designed with a 0.7 mm clearance, offer reliable stopping power in mining equipment, especially in high-load environments.

- Port Machinery: The YWZ8-300/E30, with a weight of 65 kg, is frequently found in port machinery, including container cranes, providing efficient braking control.

- Metallurgical Equipment: Used in steel production equipment like rolling mills and conveyors, these brakes, with braking torques ranging from 135 Nm to 320 Nm, play a vital role in ensuring operational safety.

- Railway Transport: The YWZ8-200/E23, with its braking torque of 135-200 Nm, is also seen in braking systems for locomotives and railcars.

Other Considerations

Humidity and Altitude: Ensure that the relative humidity does not exceed 90%, and that the operating altitude meets the GB755-2000 standard to avoid compromising brake performance.

Environmental Requirements: The YWZ8 series brakes can operate within an ambient temperature range of -20°C to 50°C. For example, the YWZ8-200/E23 model, with its compact design and 35 kg weight, is ideal for environments with such temperature variations.

Each model in the YWZ8 series electric hydraulic drum brakes is designed to be compatible with specific types of drive units, ensuring optimal performance based on the braking torque and system requirements. Here’s a description based on the drive compatibility for different models:

YWZ8-200/E23: This model is compatible with the Ed23/5 drive unit. It provides a braking torque range of 135-200 Nm, suitable for medium-duty applications requiring standard braking performance.

YWZ8-200/E30: Paired with the Ed30/5 drive unit, this model offers a higher braking torque range of 135-310 Nm, making it ideal for applications with slightly higher load requirements.

YWZ8-300/E30: This model, compatible with the Ed30/5 drive unit, provides a braking torque range of 200-320 Nm. It is well-suited for more heavy-duty applications that require a robust and reliable braking system.

YWZ8-300/E50: Designed to work with the Ed50/6 drive unit, this model provides a braking torque range of 200-550 Nm. It is intended for heavy-duty applications where a high braking force is needed.

The drive unit compatibility ensures that each brake model functions optimally, aligning the braking system’s capacity with the mechanical requirements of the specific application.

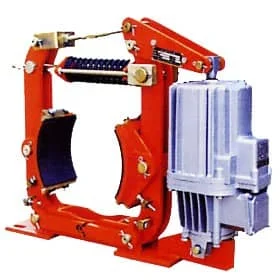

Working Principle

The YWZ8 series electric hydraulic drum brake operates using hydraulic power to generate braking force and a drum-based mechanism to stop motion. Here’s how it works:

- Hydraulic Drive: Hydraulic oil is pumped through a control valve into the hydraulic cylinder of the brake. For example, in the YWZ8-200/E23, the hydraulic system generates enough force to apply the friction pads to the drum, creating the necessary braking torque of 135-200 Nm.

- Drum Braking: In this braking system, the friction pads, activated by hydraulic pressure, press against the rotating drum. The YWZ8-300/E30, with a braking torque of 200-320 Nm, ensures smooth and reliable stopping power even under high loads.

- Clearance Adjustment: The brake’s clearance, such as the 0.7 mm clearance in the YWZ8-200/E23, ensures optimal contact between the friction pads and the drum. Adjusting the clearance is crucial for maintaining braking performance and preventing excessive wear.

The diagram above illustrates the naming convention for the YWZ8 series electric hydraulic drum brakes. The model number is broken down into several components, each representing a specific characteristic of the brake. Here’s the breakdown:

- Series Code (YWZ8): Represents the series and type of the brake.

- Brake Drum Diameter (mm): Indicates the diameter of the brake drum in millimeters.

- Brake Function Code: Refers to the additional functions of the brake, such as whether it has a specific feature or capability.

- Brake Installation Code: Identifies the type of installation required for the brake.

- Brake Force Code: Specifies the force classification of the brake.

- Drive Code:

- “E” represents the standard type.

- “B” represents the explosion-proof type.

This systematic code helps to identify and select the correct brake based on the specific requirements for a given application.

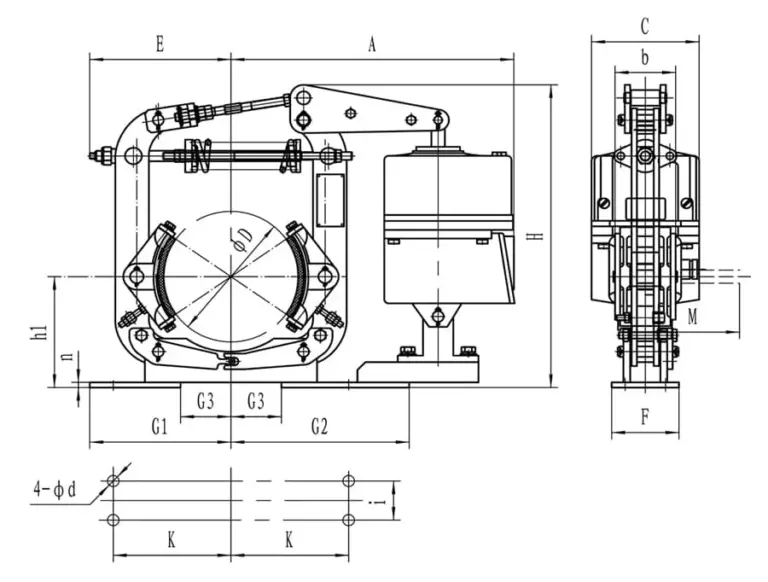

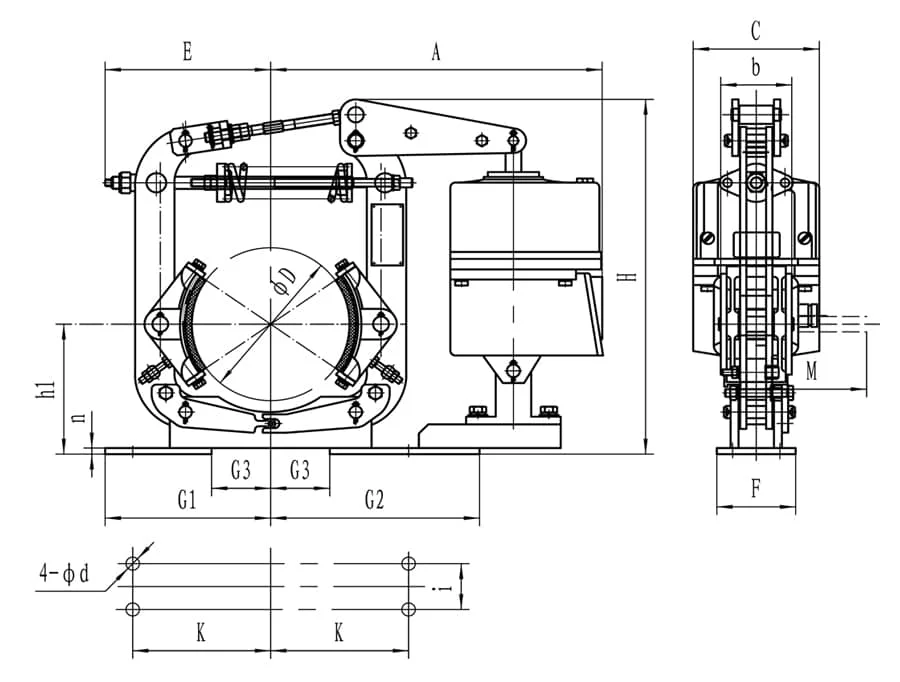

| Model | Braking torque(Nm) | Setback distance(mm) | A | b | C | D | d | E | F | G1 | G2 | H | h1 | i | k | M | n | G3 | Weight(kg) | |

| Brakes | Drive | |||||||||||||||||||

| YWZ8-200/E23 | Ed23/5 | 135-200 | 0.7 | 430 | 90 | 160 | 17 | 200 | 210 | 100 | 210 | 265 | 470 | 170 | 60 | 175(190) | 140 | 8 | 75 | 35 |

| YWZ8-200/E30 | Ed30/5 | 135-310 | 43 | |||||||||||||||||

| YWZ8-300/E30 | Ed30/5 | 200-320 | 1 | 500 | 140 | 160 | 22 | 300 | 310 | 130 | 300 | 300 | 610 | 240 | 80 | 250(270) | 180 | 12 | 120 | 65 |

| YWZs-300/E50 | Ed50/6 | 200-550 | 540 | 190 | 80 | |||||||||||||||

| YWZ8-300/E80 | Ed80/6 | 350-850 | 92 | |||||||||||||||||

| YWZ8-400/E50 | Ed50/6 | 600-750 | 1 | 660 | 180 | 190 | 22 | 400 | 355 | 180 | 350 | 400 | 760 | 320 | 130 | 325 | 220 | 14 | 150 | 120 |

| YWZ8-400/E80 | Ed80/6 | 600-1300 | 130 | |||||||||||||||||

| YWZ8-400/E121 | Ed121/6 | 850-2000 | 650 | 240 | 150 | |||||||||||||||

| YWZ8-500/E121 | Ed121/6 | 1000-2600 | 1.2 | 735 | 200 | 240 | 22 | 500 | 455 | 200 | 405 | 455 | 930 | 400 | 150 | 380 | 280 | 16 | 205 | 220 |

| YWZ8-500/E201 | Ed201/6 | 1500-3700 | ||||||||||||||||||

| YWZe-600/E121 | Ed121/6 | 1700-2800 | 1.3 | 845 | 240 | 240 | 26 | 600 | 543 | 220 | 500 | 550 | 1110 | 475 | 170 | 475 | 340 | 20 | 240 | 360 |

| YWZs-600/E201 | Ed201/6 | 1700-4300 | ||||||||||||||||||

| YWZ8-600/E301 | Ed301/6 | 3000-6500 | ||||||||||||||||||

| YWZ8-700/E201 | Ed201/6 | 3000-5000 | 1.3 | 948 | 280 | 240 | 34 | 700 | 615 | 280 | 580 | 650 | 1278 | 550 | 200 | 540 | 380 | 25 | 300 | 450 |

| YWZ8-700/E301 | Ed301/6 | 3700-8000 | ||||||||||||||||||

| YWZ8-800/E301/12 | Ed301/12 | 6000-10000 | 1.6 | 980 | 320 | 240 | 34 | 800 | 640 | 310 | 670 | 830 | 1430 | 600 | 240 | 620 | 440 | 38 | 310 | 560 |

Usage Instructions:

- Installation:

- For correct installation, ensure that the brake, such as the YWZ8-200/E23, matches the required dimensions for your equipment. The YWZ8-200/E23, for instance, has an external dimension of 430 mm (A), 90 mm (b), and 160 mm (C), making it compatible with a range of machines.

- Connect the hydraulic system properly to maintain the necessary oil flow. The hydraulic connections for the YWZ8-300/E30, with its larger dimensions (e.g., 500 mm for A and 140 mm for b), may require additional attention for optimal performance.

- Commissioning:

- Before operation, check the hydraulic system to ensure the oil pressure and flow rates are within the proper range. For example, the YWZ8-300/E30, with a braking torque of 200-320 Nm, requires sufficient hydraulic pressure for effective operation.

- Adjust the clearance between the friction pads and drum to the recommended specifications (e.g., 0.7 mm for the YWZ8-200/E23).

- Test the brake under load conditions to ensure it achieves the expected braking torque (e.g., 135-200 Nm for YWZ8-200/E23).

- Operation:

- During operation, the hydraulic system adjusts the oil flow to provide the necessary braking force. The YWZ8-300/E30, with its 200-320 Nm braking torque, ensures reliable braking performance even under heavy load conditions.

- Monitor the hydraulic oil’s cleanliness and level. For models like YWZ8-200/E23 and YWZ8-300/E30, maintaining oil quality is critical for consistent braking performance.

- Maintenance and Care:

- Inspect the wear condition of friction pads regularly. In the case of the YWZ8-200/E23, if the pads are worn out, they should be replaced to ensure braking efficiency.

- Periodically check the hydraulic system for leaks and ensure the oil remains clean. This is especially important for larger models like the YWZ8-300/E30, where hydraulic pressure plays a key role in maintaining braking torque.

- Clean the brake and surrounding components to prevent dirt or debris from impacting performance.