Port and terminal environments are among the most demanding for any industrial equipment. Ship-to-shore (STS) cranes, rail-mounted gantry (RMG) cranes, and rubber-tyred gantry (RTG) cranes operate 24/7, exposed to high winds, corrosive salt spray, and immense dynamic loads. In this high-stakes setting, the braking system is not just a component; it is the core of operational safety and efficiency.

This guide provides a technical overview of the critical braking applications in port machinery and outlines how to select the right systems to ensure maximum safety and uptime.

The First Line of Defense: Storm Brakes for Unattended Safety

The greatest external threat to a port crane is high wind. A crane left unsecured can be pushed along its rails, leading to catastrophic collisions. Storm brakes are non-negotiable safety devices designed to lock the crane in place during storms or when not in operation.

Two primary technologies dominate this application:

- Hydraulic & Electro-Hydraulic Rail Clamps: These devices use powerful jaws to clamp directly onto the rail head. Our YJGQ Type Hydraulic Rail Clamps are designed for this purpose, providing a consistent and powerful clamping force to prevent any movement. They are typically spring-applied and hydraulically released, ensuring they are fail-safe by default.

- Storm Wedge Brakes: For even greater braking force, storm wedge brakes are deployed. The YFX Series Electro-Hydraulic Storm Wedge Brakes operate by pressing a high-friction wedge against the side of the rail. This design can generate immense braking force, with models in the YFX series providing a windproof clamping force of up to 320 KN per device, making them suitable for the largest cranes in typhoon-prone regions.

[Find Your Solution: Explore our Storm Brakes – YFX Series and YJGQ Rail Clamps]

Hoisting Brakes: The Fail-Safe Guarantee for Heavy Loads

The hoist is the heart of the crane, and its braking system is paramount for preventing load drops. Hoist brakes must be “fail-safe,” meaning they are engaged by default (typically by spring force) and require power to release. In the event of a power failure, the brake automatically engages, securing the load.

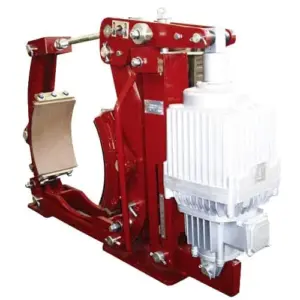

- Electro-Hydraulic Drum Brakes: A robust and proven solution, our YWZ9 and YWZ13 Series Electro-Hydraulic Drum Brakes are widely used on crane hoists. The YWZ9 series, for example, offers a maximum braking torque of 8000 Nm, suitable for a wide range of medium to heavy-duty hoists. Their enclosed design offers good protection against the elements.

- Electro-Hydraulic Disc Brakes: For applications requiring higher performance, faster response, and easier maintenance, disc brakes are the superior choice. The YPZ2 Series Electro-Hydraulic Disc Brakes offer exceptional heat dissipation and precise control. With braking torques ranging from 210 Nm to over 17,000 Nm, this series can be specified for the main hoists of the largest STS cranes, ensuring reliable performance cycle after cycle.

[Secure Your Hoist: View our YWZ9/YWZ13 Drum Brakes and YPZ2 Disc Brakes]

Travel & Trolley Brakes: Precision, Control, and Durability

The gantry travel (long travel) and trolley (cross travel) mechanisms require brakes that provide smooth, controlled deceleration to prevent load sway and ensure accurate positioning.

- Electro-Hydraulic Drum Brakes: The workhorses for travel mechanisms are our YWZ4 and YWZ8 Series Electro-Hydraulic Drum Brakes. These brakes are highly reliable and cost-effective. The YWZ4 series, for instance, is adaptable for brake wheel diameters from 200mm to 800mm, covering the full spectrum of gantry and trolley drive systems. They are equipped with self-lubricating bearings and can be fitted with wear-limit switches for predictive maintenance.

All our brakes intended for port use can be supplied with enhanced corrosion protection, including marine-grade paint, stainless steel pivot pins, and specialized seals to withstand the harsh saline environment.

[Control Your Motion: Discover our YWZ4 and YWZ8 Series for Travel Drives]

Quick Selection Reference Table

| Application | Primary Challenge | Recommended Brake Type | Our Product Series |

|---|---|---|---|

| Crane Storm Proofing | Resisting high winds, preventing derailment | Hydraulic Rail Clamp, Storm Wedge Brake | YJGQ, YFX |

| Main Hoist | Fail-safe load holding, high torque, heat dissipation | Electro-Hydraulic Disc or Drum Brake | YPZ2, YWZ9, YWZ13 |

| Gantry/Long Travel | Controlled stopping, positioning, durability | Electro-Hydraulic Drum Brake | YWZ4, YWZ8 |

| Trolley/Cross Travel | Smooth deceleration, preventing load sway | Electro-Hydraulic Drum Brake | YWZ4 |

Conclusion: A Comprehensive Braking Strategy is Key

Selecting the right brakes for port machinery is a critical engineering decision that directly impacts safety, operational uptime, and maintenance costs. A comprehensive strategy involves deploying robust storm brakes for static safety, reliable fail-safe brakes for hoisting, and durable, controllable brakes for travel motions.

Our team of engineers is ready to help you specify the optimal braking solution for your specific application, ensuring compliance with international safety standards and providing a system built to last in the world’s toughest environments.