Les actionneurs hydrauliques électriques à explosion de la série BYT sont un type d'actionneur de puissance spécifiquement conçu pour une utilisation dans des environnements à haut risque, y compris les mines de charbon, les usines chimiques, la métallurgie et la production d'énergie. Ces composants sont largement utilisés dans les systèmes de freinage industriels, les entraînements de portes, l'automatisation mécanique et d'autres domaines. Les forces fondamentales de l'entreprise reposent sur sa sécurité à l'épreuve des explosions, ses performances puissantes et sa réponse rapide, lui permettant de fonctionner de manière stable et fiable dans des environnements difficiles, garantissant ainsi la sécurité de la production et la fiabilité des équipements.

Caractéristiques techniques principales

Conception de sécurité anti-explosion

Structure anti-explosion : La série BYT dispose d'un boîtier en métal haute résistance, avec tous les composants électriques scellés dans une chambre anti-explosion. Cela respecte les normes nationales anti-explosion telles que GB3836. Elle est adaptée à une utilisation dans des lieux dangereux contenant des gaz ou des poussières explosifs.

Compatibilité avec plusieurs tensions : Ce produit est conçu pour prendre en charge le courant alternatif triphasé 127V/220V, 220V/380V, 660V/1140V et 50Hz/60Hz, garantissant qu'il répond aux exigences énergétiques d'une gamme de sites industriels.

Ce produit démontre une excellente adaptabilité environnementale.

Ce produit est capable de fonctionner dans une large plage de températures. Ce produit peut fonctionner de manière stable dans des températures environnementales allant de -20°C à 40°C.

Ce produit démontre un haut niveau de tolérance à l'humidité élevée. L'humidité relative maximale moyenne au cours du mois le plus humide est ≤90%, et le système peut fonctionner normalement même en cas de condensation de surface.

La capacité de s'adapter à des altitudes élevées. Ce produit est adapté à la plupart des zones industrielles nationales et internationales, avec une altitude allant jusqu'à 1000 mètres.

Protection contre la pollution : Ce produit est adapté à des conditions de fonctionnement complexes, car il est de classe environnementale 3, résistant à la poussière et à l'huile.

Le tableau suivant présente les paramètres de performance de l'Actionneur Électrique Hydraulique Antidéflagrant de la série BYT.

| Modèle | Force de traction/force de freinage par ressort (kg) | Course (mm) | Capacité du moteur (kW) | Tension nominale (V) | – | Temps d'actionnement vers le haut/bas (s) | Fréquence d'activation (fois/heure) | Poids (kg) |

|---|---|---|---|---|---|---|---|---|

| BYT1-18ZB/2 | 18 | 25 | 0 | 380 | – | 12 / 12 | 720 | 10 |

| BYT1-25ZB/4 | 25 | 40 | 0 | 380 | – | 12 / 16 | 720 | 13 |

| BYT1-25ZC/4 | 25 | 40 | 0 | 380 | – | 12 / 16 | 720 | 13 |

| BYT1-45Z/4 | 45 | 40 | 0 | 380 | – | 16 / 20 | 720 | 20 |

| BYT1-45Z/5 | 45 | 50 | 0 | 380 | – | 16 / 20 | 720 | 20 |

| BYT1-45Z/6 | 45 | 60 | 0 | 380 | – | 16 / 20 | 720 | 20 |

| BYT1-90Z/6 | 90 | 60 | 0 | 380 | – | 20 / 25 | 720 | 30 |

| BYT1-90Z/8 | 90 | 80 | 0 | 380 | – | 20 / 25 | 720 | 30 |

| BYT1-125Z/10 | 125 | 100 | 0 | 380 | – | 25 / 25 | 720 | 55 |

| BYT1-180Z/8 | 180 | 80 | 0 | 380 | – | 25 / 30 | 720 | 58 |

| BYT1-180Z/10 | 180 | 100 | 0 | 380 | – | 25 / 30 | 720 | 58 |

| BYT1-180Z/12 | 180 | 120 | 0 | 380 | – | 25 / 30 | 720 | 58 |

| BYT1-320Z/12 | 320 | 120 | 1 | 380 | – | 35 / 35 | 720 | 130 |

| BYT1-320Z/20 | 320 | 200 | 1 | 380 | – | 35 / 35 | 470 | 140 |

| BYT1-25/4 | 20 (Force de freinage à ressort) | 40 | 0 | 380 | – | 12 / 16 | 720 | 15 |

| BYT1-45/6 | 40 (Force de freinage à ressort) | 60 | 0 | 380 | – | 16 / 20 | 720 | 23 |

| BYT1-90/8 | 70 (Force de frein à ressort) | 80 | 0 | 380 | – | 20 / 25 | 720 | 33 |

| BYT1-125/10 | 90 (Force de frein à ressort) | 100 | 0 | 380 | – | 25 / 25 | 720 | 59 |

| BYT1-180/12 | 105 (Force de frein à ressort) | 120 | 0 | 380 | – | 25 / 30 | 720 | 63 |

Réponse d'action et durée de service

Fréquence d'action élevée : Avec une capacité allant jusqu'à 720 instances par heure, ce produit est idéal pour des applications de démarrage-arrêt à haute fréquence.

Le produit a un temps d'action court. Le temps d'action de montée/descente est compris entre 12 et 44 secondes, le temps de réponse est rapide, et l'efficacité globale du système est en cours d'amélioration.

Le produit a été conçu pour durer. Les composants clés sont fabriqués à partir de matériaux résistants à l'usure, ce qui réduit considérablement les coûts d'exploitation et de maintenance en prolongeant le cycle de maintenance.

La valeur d'application spécifique à l'industrie est la suivante.

Le produit actuel a été conçu pour prioriser la sécurité et la conformité, le rendant adapté à une utilisation dans des environnements à haut risque.

Les actionneurs antidéflagrants de la série BYT ont réussi à passer une série rigoureuse de certifications de sécurité antidéflagrante et électrique, s'établissant ainsi comme l'option préférée pour une utilisation dans les systèmes de freinage au sein de domaines industriels à haut risque, y compris l'exploitation minière de charbon, la pétrochimie et la métallurgie. Les performances de l'équipement en question ont été démontrées comme étant antidéflagrantes, garantissant ainsi que l'apparition d'étincelles électriques est efficacement empêchée de provoquer des explosions, assurant ainsi la sécurité du personnel et de l'équipement.

Le produit a démontré des niveaux de performance élevés et a été prouvé compatible avec une variété de systèmes de freinage.

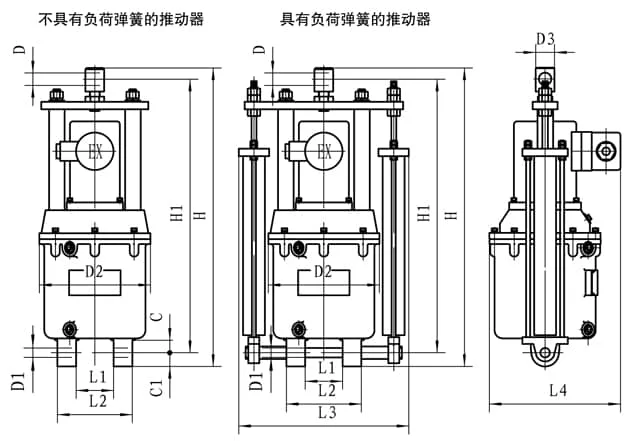

La plage de poussée, mesurée en kilogrammes, s'étend de 18 à 320, tandis que la plage de course, mesurée en millimètres, s'étend de 25 à 200. Ces composants sont compatibles avec une variété de freins industriels, de portes, de vannes et d'autres actionneurs, répondant ainsi à des exigences de charge et de course diverses.

L'objectif de cette étude est d'examiner la relation entre une haute fiabilité et la réduction des risques de temps d'arrêt.

L'appareil en question se caractérise par sa capacité de fonctionnement à haute fréquence, ce qui le rend adapté à une utilisation continue dans des lignes de production automatisées.

Il est évident que la capacité d'adaptation environnementale extensive est essentielle pour garantir la stabilité des opérations dans des environnements difficiles, caractérisés par des températures élevées, des niveaux d'humidité et une présence substantielle de poussière. Cette caractéristique est primordiale pour réduire l'incidence des pannes d'équipement attribuables à des facteurs environnementaux, améliorant ainsi la fiabilité et l'efficacité opérationnelles.

Le système a été conçu pour faciliter l'intégration et la maintenance sans faille.

L'utilisation d'interfaces et de dimensions standardisées facilite l'intégration sans faille avec les systèmes de freinage existants.

La structure compacte de l'équipement est avantageuse en termes de facilité d'entretien, ce qui réduit le temps de maintenance et améliore l'utilisation de l'équipement.

Une enquête sur les dynamiques concurrentielles du marché.

1. La comparaison suivante est faite avec des actionneurs traditionnels.

Indicateurs clés

Actionneurs antidéflagrants de la série BYT

Actionneurs hydrauliques électriques conventionnels

Performance antidéflagrante

La conception anti-explosion la rend adaptée à une utilisation dans des environnements explosifs.

Absence de protection anti-explosion. L'utilisation dans des lieux dangereux est interdite.

Adaptabilité environnementale

La capacité à résister à des températures élevées, à des niveaux d'humidité, à la condensation et à la poussière est un aspect fondamental du sujet.

Général

La fréquence opérationnelle est élevée (720 fois par heure) et la plage moyenne-basse est utilisée.

Le cycle de maintenance se caractérise par sa longueur et sa facilité d'entretien, ce qui en fait une option adaptée à un usage général.

2. Le discours suivant abordera les problèmes rencontrés par les utilisateurs.

Afin d'assurer la sécurité de l'individu concerné, le respect des réglementations de sécurité pertinentes est obligatoire. Ce texte vise à résoudre les défis associés à la sélection d'équipements dans des environnements à haut risque.

Le système a été conçu pour garantir un haut degré de fiabilité. L'objectif est de minimiser les pertes de production causées par des pannes d'équipement.

Compatibilité Diversifiée : La gamme de besoins en poussée et en course satisfaite par ce produit est vaste, garantissant une compatibilité avec une grande variété de scénarios d'application.

Les recommandations suivantes sont fournies dans le but d'acheter et de sélectionner.

Il est impératif d'élucider l'environnement d'utilisation. Dans les cas où des gaz explosifs ou de la poussière sont présents, la sélection des actionneurs antidéflagrants de la série BYT doit être priorisée.

La sélection du modèle le plus approprié doit être faite sur la base des exigences de charge : La détermination du modèle approprié dépend de l'établissement des exigences réelles de poussée et de course du frein ou de l'actionneur.

Il est impératif d'exercer une prudence quant à la compatibilité de l'alimentation électrique. Il est impératif de vérifier la tension et la fréquence de l'alimentation sur site pour garantir la cohérence avec les paramètres de l'actionneur.

La commodité de l'entretien doit également être prise en compte. Il est recommandé de choisir des modèles avec des structures compactes et un entretien facile afin de réduire les coûts opérationnels à long terme.

La conclusion tirée des arguments précédents est la suivante

Les actionneurs hydrauliques électriques antidéflagrants de la série BYT, avec leur sécurité antidéflagrante exceptionnelle, leur puissance de sortie élevée, leur excellente adaptabilité environnementale et leur capacité d'opération à haute fréquence, sont le choix idéal pour les systèmes de freinage industriels et les actionneurs automatisés. Pour les entreprises à la recherche d'une production sûre, fiable et efficace, la série BYT n'est pas seulement un choix conforme, mais aussi un élément clé pour améliorer la productivité et réduire les risques opérationnels.