Pengereman Presisi untuk Kontrol Gerakan Industri

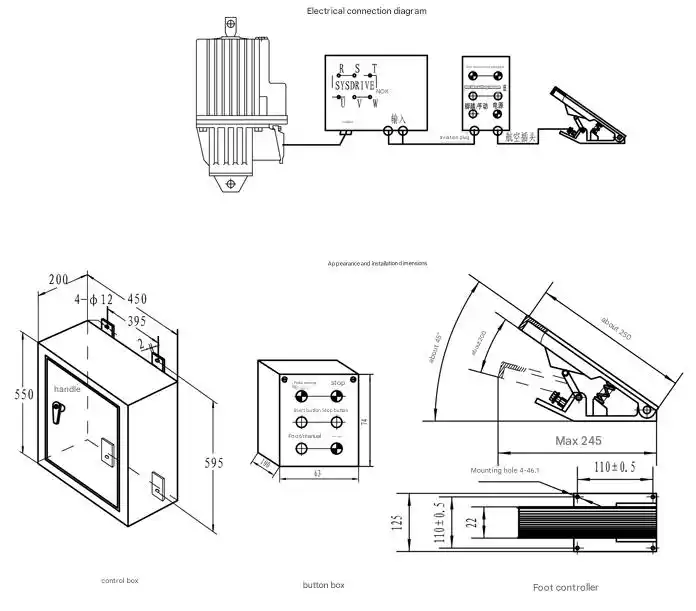

Pengendali Frekuensi Variabel Pedal Kaki TPK dirancang untuk aplikasi industri yang membutuhkan tinggi, termasuk mekanisme putar crane dan sistem penggerak troli. Dengan mengintegrasikan teknologi konversi frekuensi canggih dengan input pedal kaki, pengendali TPK memungkinkan modifikasi gaya pengereman yang tepat dan real-time—memberikan perlambatan yang lebih halus dan penghentian yang lebih aman untuk mesin berat.

Cara kerjanya

Tidak seperti sistem pengereman konvensional, yang bergantung pada kontrol tetap atau bertahap, pengontrol TPK mengubah amplitudo sinyal pedal kaki secara langsung menjadi frekuensi output yang bervariasi. Frekuensi ini kemudian digunakan untuk menyesuaikan kecepatan dan dorongan motor aktuator dengan presisi, memberikan kontrol torsi pengereman yang proporsional dan terus menerus. Hubungan linier antara posisi pedal dan gaya pengereman memungkinkan operator untuk mengelola perlambatan secara intuitif, sehingga meminimalkan beban kejutan dan mengurangi keausan pada komponen mekanis.

Kontrol multi-drive yang disinkronkan

Pengendali TPK mendukung sinkronisasi multi-drive, memastikan bahwa beberapa aktuator beroperasi secara bersamaan. Fitur ini sangat penting untuk crane dan sistem gantry berskala besar, karena pengereman yang tidak merata dapat menyebabkan ketidakselarasan atau stres struktural. Sistem TPK mendistribusikan sinyal kontrol secara cerdas untuk mempertahankan kinerja pengereman yang konsisten di semua drive yang terhubung.

Spesifikasi teknis:

- Suhu operasi: -10°C hingga 40°C di lingkungan yang tidak korosif dan bebas debu.

- Sumber daya: 380 V, 50 Hz (standar industri)

- Siklus tugas: S3-60% (operasi intermiten)

- Panjang kabel maksimum: 30 meter antara pengontrol dan motor.

- Kompatibilitas aplikasi: Dirancang untuk integrasi dengan berbagai rem elektromagnetik dan hidrolik industri.

Skenario Aplikasi

- Derek overhead dan gantry: Rem penggerak putar, troli, dan jembatan.

- Peralatan pelabuhan:

- Derek kontainer

- Pengangkut kapal

- Mesin pengangkat berat

- Metalurgi dan pertambangan: Lingkungan pengereman beban berat frekuensi tinggi

- Jalur produksi otomatis: Sistem yang memerlukan kontrol pengereman multi-titik yang disinkronkan.

Manfaat Berbasis Data

- Keamanan yang Ditingkatkan: Penelitian menunjukkan bahwa sistem pengereman frekuensi variabel dapat mengurangi jarak berhenti hingga 25% dibandingkan dengan rem kontrol tetap tradisional, sehingga secara signifikan mengurangi risiko kecelakaan dalam aplikasi dengan massa tinggi.

- Pemeliharaan yang Dikurangi: Pengendali TPK dirancang untuk memfasilitasi penghentian yang halus dan bebas guncangan, yang berkontribusi pada pengurangan keausan mekanis dan memperpanjang umur layanan baik aktuator maupun bantalan rem. Data industri menunjukkan potensi pengurangan biaya pemeliharaan sebesar 20–30% untuk sistem yang ditingkatkan ke kontrol frekuensi variabel.

- Efisiensi Energi: Modulasi frekuensi mengoptimalkan operasi motor, sehingga mengurangi konsumsi daya yang tidak perlu selama siklus pengereman.

Mengapa Memilih Pengendali Frekuensi Variabel Pedal Kaki TPK?

- Kontrol Linier yang Sebenarnya: Hubungan langsung dan proporsional antara input pedal dan gaya pengereman untuk penanganan yang tepat.

- Sinkronisasi Multi-Drive: Memastikan pengereman yang seimbang di seluruh sistem multi-aktuator yang kompleks.

- Keandalan Terbukti: Dirancang untuk lingkungan industri yang keras, dengan perlindungan listrik dan mekanik yang kuat.

- Integrasi Fleksibel: Kompatibel dengan instalasi baru dan proyek retrofit.