Точное торможение для промышленного управления движением

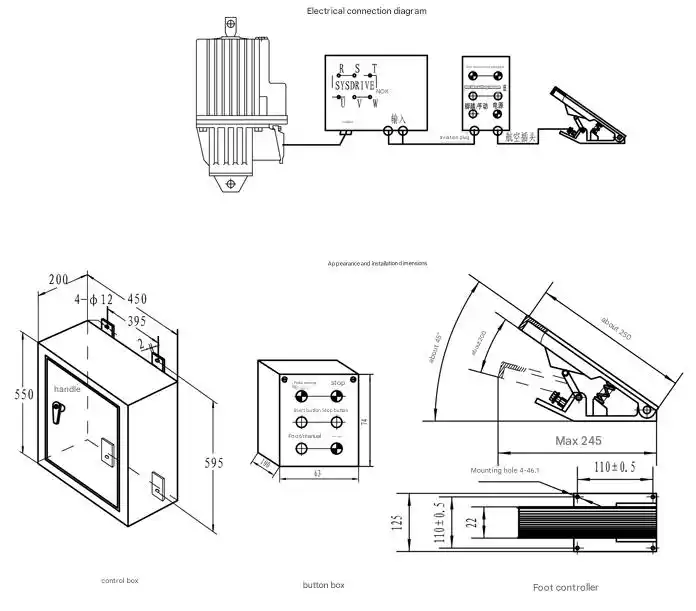

Переменный частотный контроллер TPK с педалью управления разработан для высоконагруженных промышленных приложений, включая механизмы поворота кранов и системы привода тележек. Интегрируя передовые технологии преобразования частоты с управлением с помощью педали, контроллер TPK обеспечивает точную, в реальном времени модуляцию тормозной силы, обеспечивая более плавное замедление и более безопасные остановки для тяжелой техники.

Как это работает

В отличие от традиционных тормозных систем, которые полагаются на фиксированное или ступенчатое управление, контроллер TPK преобразует амплитуду сигнала педали в переменную выходную частоту. Эта частота затем используется для точной регулировки скорости и тяги двигателя привода, обеспечивая пропорциональное и непрерывное управление тормозным моментом. Линейная зависимость между положением педали и тормозной силой позволяет операторам интуитивно управлять замедлением, тем самым минимизируя ударные нагрузки и снижая износ механических компонентов.

Синхронизированное управление несколькими приводами

Контроллер TPK поддерживает синхронизацию нескольких приводов, обеспечивая одновременную работу нескольких актуаторов. Эта функция необходима для крупногабаритных кранов и портальных систем, так как неравномерное торможение может привести к несоответствию или структурному напряжению. Система TPK интеллектуально распределяет управляющие сигналы, чтобы поддерживать стабильную производительность торможения на всех подключенных приводах.

Технические характеристики:

- Рабочая температура: от -10°C до 40°C в некоррозионных, безпыльных условиях.

- Электропитание: 380 В, 50 Гц (промышленный стандарт)

- Рабочий цикл: S3-60% (прерывистая работа)

- Максимальная длина кабеля: 30 метров между контроллером и мотором.

- Совместимость применения: разработан для интеграции с широким спектром промышленных электромагнитных и гидравлических тормозов.

Сценарии применения

- Подъемные и мостовые краны: Торможение поворота, тележки и моста.

- Портовое оборудование:

- Контейнерные краны

- Разгрузчики судов

- Тяжелая подъемная техника

- Металлургия и горное дело: Среды торможения с высокой частотой и тяжелыми нагрузками

- Автоматизированные производственные линии: Системы, требующие синхронизированного многоточечного управления торможением

Преимущества, основанные на данных

- Повышенная безопасность: Исследования показывают, что системы торможения с переменной частотой могут сократить расстояние остановки до 25% по сравнению с традиционными тормозами с фиксированным управлением, что значительно снижает риск аварий в приложениях с высокой массой.

- Сниженное обслуживание: Контроллер TPK разработан для обеспечения плавных, безударных остановок, что способствует снижению механического износа и увеличению срока службы как актуаторов, так и тормозных колодок. Данные отрасли указывают на потенциальное снижение затрат на обслуживание на 20–30% для систем, модернизированных до управления с переменной частотой.

- Энергоэффективность: Частотная модуляция оптимизирует работу мотора, тем самым снижая ненужное потребление энергии во время тормозных циклов.

Почему стоит выбрать переменный частотный контроллер TPK с педалью?

- Истинное линейное управление: Прямое, пропорциональное соотношение между входом педали и тормозной силой для точного управления.

- Мульти-драйв синхронизация: Обеспечивает сбалансированное торможение в сложных системах с несколькими актуаторами.

- Доказанная надежность: Разработан для жестких промышленных условий, с надежной электрической и механической защитой.

- Гибкая интеграция: Совместим как с новыми установками, так и с проектами по модернизации.