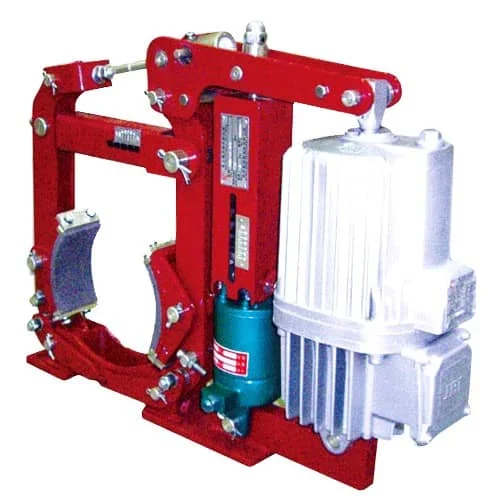

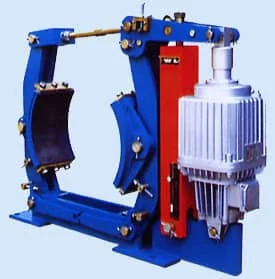

YWZ13 series electric hydraulic drum brake is an important device that provides safe and reliable braking and quick release functions in high-frequency and high-intensity application environments. It is widely used in heavy-duty mechanical equipment such as ports, metallurgy, and mining.

Model Naming Rules

YWZ13 Series Electro-Hydraulic Drum Brake – Model Designation Guide

The model code for the YWZ13 series is structured as follows:

YWZ13 – Brake Wheel Diameter / Actuator Type Thrust Code Additional Devices Optional Functions

Each section of the model code indicates:

- YWZ13: Series code indicating an electro-hydraulic drum brake (13th generation)

- Brake Wheel Diameter: In millimeters (e.g., 300 = 300 mm)

- Actuator Type:

- “E” = Standard Ed series actuator

- “B” = Explosion-proof type actuator

- Thrust Code: Indicates actuator thrust (e.g., 30, 50, 90)

- Additional Devices (optional): Such as manual release mechanisms

- Optional Function Codes (optional): Indicate extended features and configurations; can be combined as needed

Optional Function Codes:

Code Function Description M Automatic lining wear compensation device K1 Brake open (rising) limit switch K2 Brake close (lowering) limit switch K3 Lining wear limit indication switch S1 Left-side manual release device S2 Right-side manual release device Example:

YWZ13-300/E50MK1S1

This model indicates a YWZ13 series brake with a 300 mm brake wheel, standard Ed50 actuator, equipped with:Left-side manual release (S1)

Lining wear compensation (M)

Brake open limit switch (K1)

Technical parameters and dimensions

| Model | Braking torque(Nm) | Setback distance(mm) | A | B | C | D | d | E | F | Gi | G2 | H/Hmcx | hi | i | k | M | n | L | G3 | Weight(kg) | |

| Brakes | Drive | ||||||||||||||||||||

| YWZ13-200/E23 | Ed23/5 | 100-200 | 0.7 | 470 | 90 | 160 | 200 | 17 | 175 | 100 | 210 | 265 | 510 | 170 | 60 | 175(190) | 140 | 8 | 150 | 75 | 32 |

| YWZ13-200/E30 | Ed30/5 | 140-315 | 43 | ||||||||||||||||||

| YWZ13-300/E30 | Ed30/5 | 250-400 | 8 | 590 | 140 | 160 | 300 | 22 | 255 | 130 | 295 | 330 | 605 | 240 | 80 | 250(270) | 180 | 12 | 170 | 135 | 65 |

| YWZ13-300/E50 | Ed50/6 | 400-630 | 630 | 190 | 80 | ||||||||||||||||

| YWZ13-300/E80 | Ed80/6 | 630-1000 | 92 | ||||||||||||||||||

| YWZ13-400/E50 | Ed50/6 | 400-800 | 1.2 | 710 | 180 | 190 | 400 | 22 | 310 | 180 | 350 | 420 | 755 | 320 | 130 | 325 | 220 | 14 | 170 | 150 | 120 |

| YWZ13-400/E80 | Ed80/6 | 630-1250 | 130 | ||||||||||||||||||

| YWZ13-400/E121 | Ed121/6 | 1000-2000 | 700 | 240 | 813/830 | 150 | |||||||||||||||

| YWZ13-500/E80 | Ed80/6 | 800-1600 | 1.2 | 810 | 200 | 240 | 500 | 22 | 380 | 200 | 405 | 535 | 900 | 400 | 150 | 380 | 280 | 16 | 180 | 205 | 220 |

| YWZ13-500/E121 | Ed121/6 | 1250-2500 | 800 | 900/920 | |||||||||||||||||

| YWZ13-500/E201 | Ed201/6 | 2000-4000 | |||||||||||||||||||

| YWZ13-600/E121 | Ed121/6 | 1800-2800 | 1.3 | 925 | 240 | 240 | 600 | 26 | 470 | 220 | 500 | 600 | 1080 | 475 | 170 | 475 | 340 | 20 | 185 | 240 | 305 |

| YWZ13-600/E201 | Ed201/6 | 2500-4500 | |||||||||||||||||||

| YWZ13-600/E301 | Ed301/6 | 4000-6500 | |||||||||||||||||||

| YWZ13-700/E201 | Ed201/6 | 2500-5600 | 1.3 | 980 | 280 | 240 | 700 | 34 | 530 | 270 | 570 | 650 | 1290 | 550 | 200 | 540 | 380 | 25 | 220 | 300 | 425 |

| YWZ13-700/E301 | Ed301/6 | 4000-8000 | |||||||||||||||||||

| YWZ13-800/E301 | Ed301/12 | 12500 | 2.0 | 1230 | 320 | 240 | 800 | 34 | 600 | 310 | 670 | 830 | 1430 | 600 | 240 | 620 | 420 | 34 | 240 | 310 | 545 |

Note: ① If the installation dimensions are in brackets, please specify when ordering. ② The specific model and structural dimensions are subject to change.

YWZ13 Series Electro-Hydraulic Drum Brakes

The YWZ13 series drum brakes are available in multiple models to suit various braking torque requirements and installation conditions. Each model is configured with a matching Ed series electro-hydraulic thruster and offers different mechanical dimensions. Below is a summary of key parameters:

- Braking Torque Range

Each model provides a defined range of braking torque, for example:- YWZ13-200/E23: 100–200 Nm

- YWZ13-300/E80: 630–1000 Nm

- YWZ13-400/E121: 1000–2000 Nm

- YWZ13-500/E80: 800–1600 Nm

- This allows for flexible adaptation to different load conditions.

- Matching Electro-Hydraulic Thruster

The drive unit used is an Ed series thruster such as Ed23/5, Ed30/5, Ed80/6, or Ed121/6, selected based on the required thrust and stroke. - Setback Distance

Some models specify a setback distance (e.g., 0.7 mm for YWZ13-200/E23, 8.0 mm for YWZ13-300/E30), which is the distance the brake arms move when disengaged. - Key Installation Dimensions

A, B, C, D, E: Basic mounting widths and hole spacing (in mm) - d: Shaft or bolt hole diameter

- H / Hmax: Overall height or installation height range

- L, G1, G2, G3: Mounting flange distances

- hi, i, k, M, n: Lever arms, mounting holes, and structural limits

For instance:

YWZ13-300/E30:

A = 590 mm, B = 140 mm, C = 160 mm

D = 300 mm, d = 22 mm, E = 255 mm

H = 605 mm, Weight = 65 kg

YWZ13-500/E80:

A = 810 mm, B = 200 mm, C = 240 mm

D = 500 mm, d = 22 mm, E = 380 mm

H = 900 mm, Weight = 220 kg

Weight

The net weight varies by model and configuration:

From 32 kg for smaller models (YWZ13-200/E23)

Up to 220 kg for larger models (YWZ13-500/E80)

General Notes

Not all dimensional values are filled in for every model — actual configuration may depend on optional features or customer-specific requirements.

Dimensional consistency is based on JB/ZQ4388-1997 standard. For more precise dimensioning (e.g., hole positions or interface clearance), refer to CAD drawings or manufacturer’s detail sheet.