Ed Series Electro-Hydraulic Thrusters: The Intelligent Heart of Industrial Motion Control

The Ed series electro-hydraulic thruster is a compact, self-contained drive unit engineered to deliver precise, powerful, and reliable linear motion for a vast range of industrial applications. By seamlessly integrating a motor, centrifugal pump, and cylinder, it serves as the core actuator for:

- Industrial Brake Systems: Providing fail-safe release for block and disc brakes.

- Flow Control: Driving industrial valves and gates with precision.

- Mechanical Movement: Powering directional swings, rotations (up to 90°), and clamping devices.

Adhering to rigorous DIN 15430 and JB/T 10603-2006 standards, and built upon technology from the former German EMG company, every Ed thruster is a testament to quality and performance.

Advantages: Engineered for Your Demanding Applications

Why choose the Ed series for your next project? Because every feature is designed to solve a real-world industrial challenge.

1. Unmatched Reliability & Performance

- Robust Construction: The lightweight, fully sealed aluminum alloy shell (IP65 protection) ensures durability even in environments with high humidity or corrosive media.

- High-Endurance Motor: A non-oil-immersed motor with F-class insulation guarantees excellent heat resistance and a long operational lifespan, capable of up to 2000 cycles per hour (S3-60% duty cycle on standard models).

2. Precision Control Tailored to Your Needs

- Smooth, Shock-Free Operation: The hydraulic transmission ensures gentle actuation, reducing mechanical stress on your equipment.

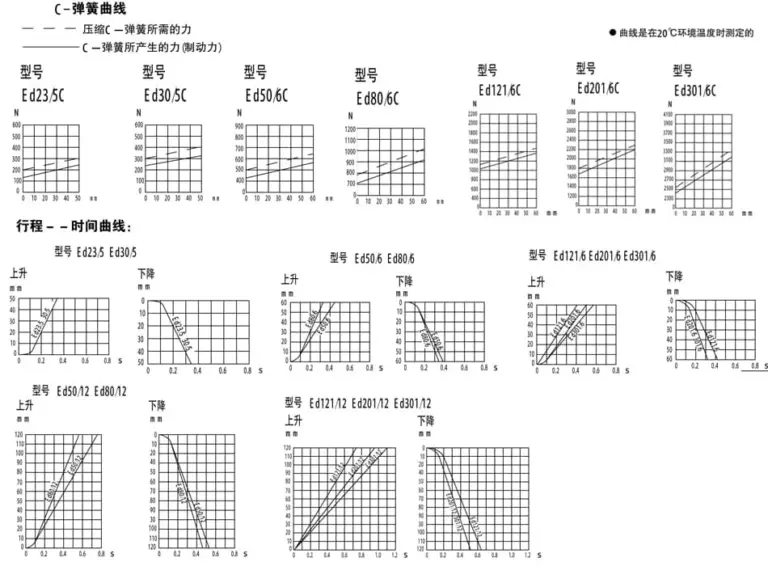

- Customizable Speed: Enhance your control by adding ascent (H) and descent (S) delay valves, allowing you to fine-tune the operational speed to prevent load swing or system shock.

- Position Feedback: Integrate limit switches (E1, E2, EB) to send brake open/closed status signals back to your PLC, enabling smarter, automated control.

3. Versatility Across a Comprehensive Range

- Wide Performance Spectrum: Our range covers everything from the compact Ed 23/5 (220N thrust, 50mm stroke) to the powerhouse Ed 630/12 (6300N thrust, 120mm stroke), ensuring a perfect match for any load.

- Flexible Installation: Thrusters can be installed vertically or horizontally. The mounting base on models Ed 50 through Ed 301 can be rotated 90°, offering unparalleled installation flexibility.

4. Built for Extreme Environments

- Wide Temperature Range: Standard units operate flawlessly from -20°C to +50°C. For colder climates, an optional heater (R) can be integrated.

- Anti-Corrosion Options: Specialized anti-corrosion treatments are available for marine or chemically aggressive environments.

Working Principle: The Power of Controlled Hydraulic Force

The Ed thruster’s operation is elegantly simple and inherently fail-safe.

- Activation: When power is on, the internal motor drives a centrifugal impeller.

- Pressure Build-Up: The impeller generates hydraulic pressure, forcing oil to act upon a piston.

- Linear Motion: The piston and its attached push rod rise smoothly, compressing the brake’s main spring and releasing the brake.

- Fail-Safe Deactivation: Upon power loss, hydraulic pressure dissipates instantly. The brake’s spring force pushes the piston back, ensuring the brake engages immediately and safely holds the load.

Technical Specifications & Model Selection

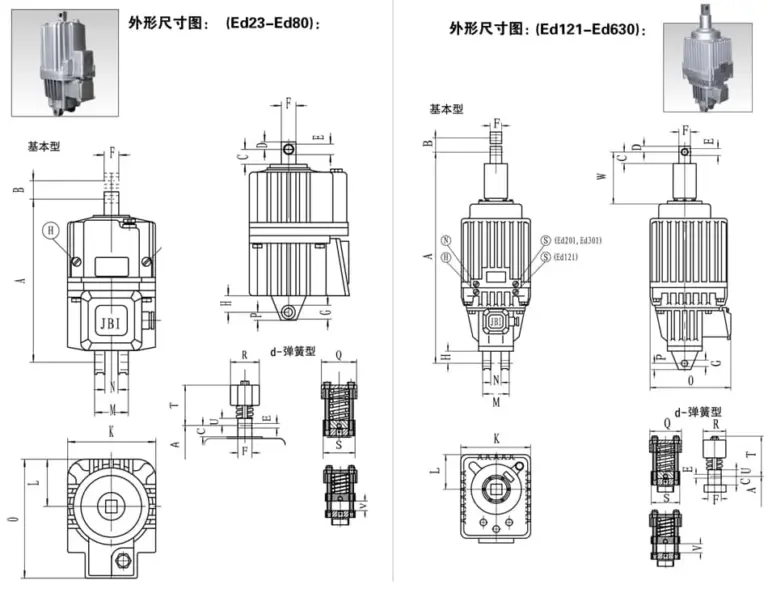

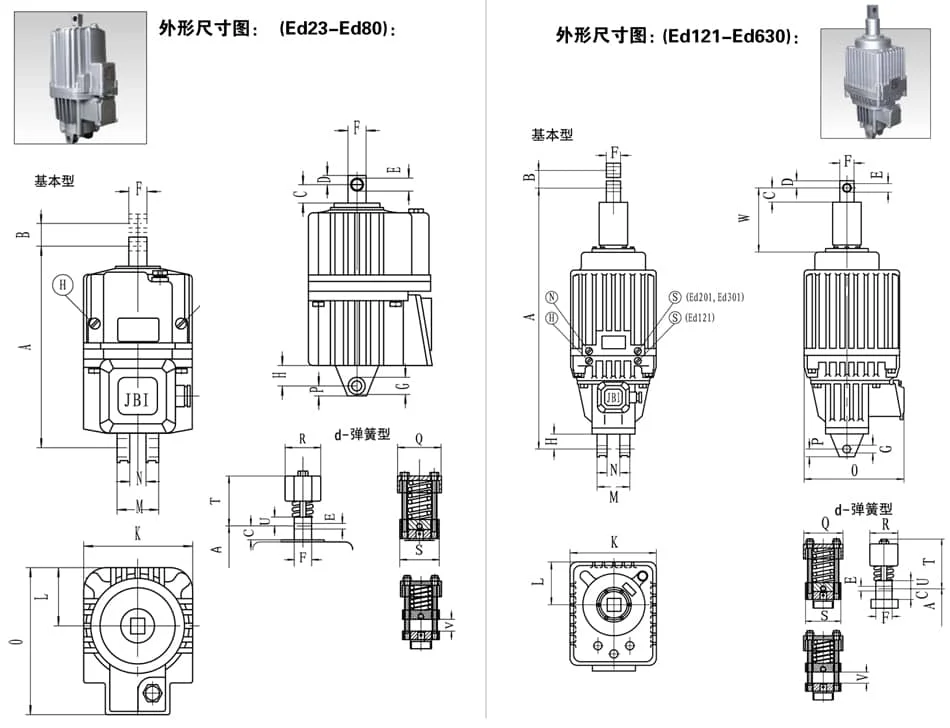

Selecting the right thruster is critical for system safety and performance. Use the table below to find the model that precisely meets your force, stroke, and dimensional requirements.

| Model | Rated Thrust (N) | Rated Stroke (mm) | Input Power (W) | Weight (Kg) | Key Dimensions (A x K x L) in mm |

|---|---|---|---|---|---|

| Ed 23/5 | 220 | 50 | 165 | 10 | 286 x 160 x 80 |

| Ed 30/5 | 300 | 50 | 200 | 14 | 370 x 160 x 80 |

| Ed 50/6 | 500 | 60 | 210 | 21 | 435 x 190 x 95 |

| Ed 80/6 | 800 | 60 | 330 | 24 | 450 x 190 x 95 |

| Ed 121/6 | 1250 | 60 | 330 | 39 | 645 x 240 x 112 |

| Ed 201/6 | 2000 | 60 | 450 | 39 | 645 x 240 x 112 |

| Ed 301/6 | 3000 | 60 | 550 | 40 | 645 x 240 x 112 |

| Ed 80/12 | 800 | 120 | 330 | 27 | 530 x 190 x 95 |

| Ed 121/12 | 1250 | 120 | 330 | 39 | 705 x 240 x 112 |

| Ed 201/12 | 2000 | 120 | 450 | 39 | 705 x 240 x 112 |

| Ed 301/12 | 3000 | 120 | 550 | 40 | 705 x 240 x 112 |

| Ed 630/12 | 6300 | 120 | 1100 | – | 865 x 270 x 127 |

For complete dimensional data, please refer to the technical drawing or contact our support team. Voltage and frequency can be customized (e.g., 400V, 415V, 60Hz).

Customization & Accessories: Build Your Perfect Thruster

Enhance the functionality of your Ed thruster with a range of bolt-on accessories.

| Code | Accessory | Function |

|---|---|---|

| H / S | Delay Valves | Adjusts ascent (H) or descent (S) time for soft actuation. |

| E1 / E2 | Limit Switches | Provides mechanical position feedback (e.g., brake released/closed). |

| EB | Inductive Switch | Offers contactless position sensing for high-frequency applications. |

| R | Heater | Ensures reliable operation in ambient temperatures below -20°C. |

| C / M / D | Internal Springs | Adds brake spring force (C), reset force (M), or buffering (D). |

Example: An Ed 121/6-S-E2 is a thruster with 1250N thrust, 60mm stroke, equipped with a descent delay valve and a “brake closed” limit switch.

Installation & Usage Best Practices

- Mounting: Ensure the piston rod is aligned with the load to avoid radial forces, which can impact performance and lifespan.

- Environment: For highly corrosive or dusty areas, please specify the need for special seals or anti-corrosion treatment when ordering.

- Electrical: Confirm your supply voltage and frequency. All units are tested before shipment to meet your specified electrical requirements.

Choose the Ed Series Electro-Hydraulic Thruster for a powerful, precise, and reliable braking experience. Contact our technical team today to confirm the ideal model and configuration for your application or to request a quote.