Klem Rel Hidrolik Berat YDGZ-40: Rem Badai Terbaik untuk Crane

Di lingkungan di mana angin kencang dan cuaca yang tak terduga menjadi ancaman konstan, melindungi aset bernilai jutaan seperti crane gantry dan mesin pelabuhan bukan hanya prioritas—itu sebuah keharusan. Klem Rel Hidrolik YDGZ-40 adalah rem badai yang kuat dan aman yang dirancang untuk memberikan cengkeraman tak tergoyahkan, memastikan peralatan penting Anda tetap terparkir dengan aman dan terlindungi dari gaya paling kuat.

Dirancang untuk kondisi menantang di pelabuhan, galangan kapal, dan situs industri berat, rem rel crane ini memberikan keselamatan dan keandalan operasional yang tak tergoyahkan. Ini adalah solusi definitif untuk parkir dan pengereman darurat pada semua jenis mesin besar yang dipasang di rel.

Desain yang Secara Inheren Aman dari Kegagalan: Terapan Pegas, Pelepasan Hidraulik

Di inti profil keselamatan unggul YDGZ-40 adalah desainnya yang fail-safe, biasa tertutup.

- Kekuatan Pengereman: Diaplikasikan oleh satu set pegas cakram tugas berat yang telah dimuat sebelumnya.

- Mekanisme Pelepasan: Diaktifkan oleh sistem hidraulik industri standar (8 MPa).

Ini berarti rem selalu berada dalam posisi “aktif” secara default. Jika terjadi pemadaman listrik atau hilangnya tekanan hidrolik, pegas secara otomatis dan instan menerapkan gaya pengereman penuh. Mekanisme rem diterapkan oleh pegas, dilepas secara hidrolik ini memberikan ketenangan pikiran, mengetahui aset Anda aman bahkan selama pemadaman total.

Daya Pegang Tak Tertandingi: Kekuatan Penjepit 400 KN

YDGZ-40 memberikan 400 KN (sekitar 40,8 ton metrik) gaya penjepit vertikal yang kuat langsung ke rel. Kekuatan besar ini, dihasilkan melalui mekanisme tuas yang efisien, menciptakan kunci gesekan yang kuat yang penting untuk:

- Mencegah gerakan struktur besar dalam kondisi angin kencang.

- Parkir yang aman derek gantry berat dan derek ship-to-shore (STS).

- Menyediakan pengereman darurat yang andal ketika diintegrasikan ke dalam sistem kontrol crane.

Dibangun untuk Seumur Hidup: Konstruksi Industri Tugas Berat

Dengan berat 1110 kg, YDGZ-40 adalah bukti rekayasa berkekuatan berat. Bodinya yang kokoh dibangun untuk menahan getaran ekstrem, beban kejut, dan atmosfer korosif yang umum di lingkungan laut dan pelabuhan. Blok gesek dibuat dengan pemesinan presisi dari baja tahan aus tingkat lanjut, menjamin kinerja konsisten dan masa pakai lama dengan perawatan minimal.

Direkayasa untuk Uptime: Instalasi Cepat & Penggantian Manual

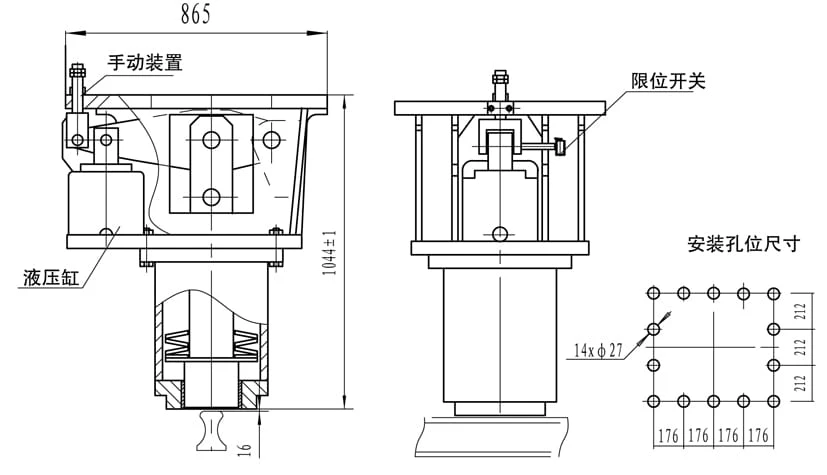

Memahami kebutuhan akan efisiensi operasional, YDGZ-40 dirancang dengan fitur-fitur yang menyederhanakan integrasi dan pemeliharaan:

- Sakelar Batas Onboard: Memberikan sinyal "dijepit" dan "dilepaskan" yang jelas ke PLC utama, mencegah aktivasi drive yang tidak disengaja saat rem diaktifkan dan mengonfirmasi kondisi aman.

- Pelepasan Manual yang Nyaman: Dilengkapi dengan pegangan pelepas manualpenjepit rel ini dapat dilepaskan tanpa tenaga hidrolik. Fitur ini sangat berharga selama pemasangan, commissioning, dan pemeliharaan darurat, sehingga menghemat waktu dan sumber daya yang sangat penting.

Aplikasi Utama

YDGZ-40 adalah pilihan ideal untuk memberikan perlindungan badai dan keamanan parkir untuk berbagai macam peralatan:

- Derek Pelabuhan & Terminal (Kapal-ke-Pantai, Gantry Berikat Karet, Gantry yang Dipasang di Rel)

- Derek Galangan Kapal & Goliath

- Derek Gantry Industri & Overhead Crane

- Penimbun-Penimbun Ulang (Stacker-Reclaimers) & Peralatan Penanganan Massal

Spesifikasi Teknis

| Parameter | Nilai |

|---|---|

| Model | YDGZ-40 |

| Nilai Kekuatan Penjepit | 400 KN |

| Tekanan Hidraulik yang Bekerja | 8 MPa |

| Stroke Plunger | 16 mm |

| Berat | 1110 Kg |

| Suhu Pengoperasian | 0°C hingga 40°C |

| Kelembaban Relatif | ≤ 90% |

Amankan Aset Anda Hari Ini

Ketika menyangkut melindungi peralatan Anda yang paling berharga, tidak ada ruang untuk kompromi. YDGZ-40 Klem Rel Hidrolik menawarkan daya terbukti, keandalan fail-safe, dan konstruksi tahan lama yang dibutuhkan operasi Anda.

Apakah Anda sedang menentukan spesifikasi untuk crane baru atau mencari pengganti yang andal untuk rem rel yang ada, tim kami siap membantu. Hubungi kami hari ini untuk penawaran detail, konsultasi teknis, atau untuk membahas bagaimana memilih klem rel yang tepat untuk aplikasi berangin kencang Anda.