YDGZ-40 Heavy-Duty Hydraulic Rail Clamp: The Ultimate Storm Brake for Cranes

In environments where high winds and unpredictable weather pose a constant threat, protecting multi-million dollar assets like gantry cranes and port machinery isn’t just a priority—it’s a necessity. The YDGZ-40 Hydraulic Rail Clamp is a robust, fail-safe storm brake engineered to provide an unyielding grip, ensuring your critical equipment remains securely parked and protected against the most powerful forces.

Designed for the demanding conditions of ports, shipyards, and heavy industrial sites, this crane rail brake delivers uncompromising safety and operational reliability. It is the definitive solution for parking and emergency braking on all types of large, rail-mounted machinery.

Inherently Fail-Safe Design: Spring Applied, Hydraulic Release

At the core of the YDGZ-40’s superior safety profile is its fail-safe, normally closed design.

- Braking Force: Applied by a powerful set of pre-loaded, heavy-duty disc springs.

- Release Mechanism: Activated by a standard industrial hydraulic system (8 MPa).

This means the brake is always in the “on” position by default. In the event of a power failure or loss of hydraulic pressure, the springs automatically and instantly apply the full braking force. This spring applied, hydraulic release brake mechanism provides peace of mind, knowing your assets are secure even during a complete power outage.

Unmatched Holding Power: 400 KN of Clamping Force

The YDGZ-40 delivers a formidable 400 KN (approximately 40.8 metric tons) of vertical clamping force directly onto the rail. This immense power, generated through an efficient lever mechanism, creates a powerful friction lock that is essential for:

- Preventing movement of large structures in high-wind conditions.

- Securely parking heavy gantry cranes and ship-to-shore (STS) cranes.

- Providing reliable emergency braking when integrated into the crane’s control system.

Built for a Lifetime: Heavy-Duty Industrial Construction

Weighing in at 1110 kg, the YDGZ-40 is a testament to heavy-duty engineering. Its rugged body is built to withstand extreme vibrations, shock loads, and the corrosive atmospheres common in marine and port environments. The friction blocks are precision-machined from advanced high-wear-resistant steel, guaranteeing consistent performance and a long service life with minimal maintenance.

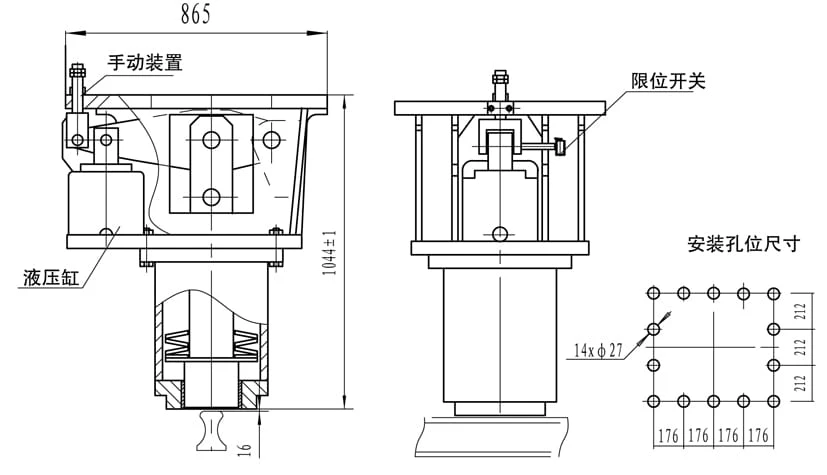

Engineered for Uptime: Fast Installation & Manual Override

Understanding the need for operational efficiency, the YDGZ-40 is designed with features that simplify integration and maintenance:

- Onboard Limit Switches: Provide clear “clamped” and “released” signals to the main PLC, preventing accidental drive activation while the brake is engaged and confirming a safe state.

- Convenient Manual Release: Equipped with a manual release handle, this rail clamp can be disengaged without hydraulic power. This feature is invaluable during installation, commissioning, and emergency maintenance, saving critical time and resources.

Primary Applications

The YDGZ-40 is the ideal choice for providing storm protection and parking safety for a wide range of equipment:

- Port & Terminal Cranes (Ship-to-Shore, Rubber-Tyred Gantry, Rail-Mounted Gantry)

- Shipyard Cranes & Goliaths

- Industrial Gantry Cranes & Overhead Cranes

- Stacker-Reclaimers & Bulk Handling Equipment

Technical Specifications

| Parameter | Value |

|---|---|

| Model | YDGZ-40 |

| Rated Clamping Force | 400 KN |

| Working Hydraulic Pressure | 8 MPa |

| Plunger Stroke | 16 mm |

| Weight | 1110 Kg |

| Operating Temperature | 0°C to 40°C |

| Relative Humidity | ≤ 90% |

Secure Your Assets Today

When it comes to protecting your most valuable equipment, there is no room for compromise. The YDGZ-40 Hydraulic Rail Clamp offers the proven power, fail-safe reliability, and durable construction your operations demand.

Whether you are specifying a new crane or seeking a reliable replacement for an existing rail brake, our team is ready to assist. Contact us today for a detailed quote, technical consultation, or to discuss how to select the right rail clamp for your high-wind application.