YDGZ-40 Grampo Hidráulico para Carril de Serviço Pesado: O Travão de Tempestade Definitivo para Gruas

Em ambientes onde ventos fortes e condições meteorológicas imprevisíveis representam uma ameaça constante, proteger ativos de milhões de dólares, como gruas pórtico e maquinaria portuária, não é apenas uma prioridade—é uma necessidade. O Grampo Hidráulico para Carril YDGZ-40 é um travão de tempestade robusto e de segurança intrínseca, concebido para fornecer uma aderência inabalável, garantindo que o seu equipamento crítico se mantenha estacionado de forma segura e protegido contra as forças mais poderosas.

Concebido para as condições exigentes de portos, estaleiros navais e locais industriais pesados, este travão de carril para grua oferece segurança e fiabilidade operacional sem compromissos. É a solução definitiva para estacionamento e travagem de emergência em todos os tipos de maquinaria de grande porte montada sobre carris.

Design inerentemente à prova de falhas: Mola aplicada, libertação hidráulica

No cerne do perfil de segurança superior do YDGZ-40 está o seu design fail-safe, normalmente fechado.

- Força de travagem: Aplicado por um poderoso conjunto de molas de disco pré-carregadas e resistentes.

- Mecanismo de libertação: Ativado por um sistema hidráulico industrial normalizado (8 MPa).

Isto significa que o travão está sempre na posição “ligado” por defeito. No caso de perda de energia ou de pressão hidráulica, as molas aplicam automática e instantaneamente a força total de travagem. Este mecanismo de travão com ação por mola e libertação hidráulica oferece tranquilidade, sabendo que os seus ativos estão seguros mesmo durante uma falha total de energia.

Poder de fixação inigualável: 400 KN de força de aperto

O YDGZ-40 fornece uma formidável 400 KN (aproximadamente 40,8 toneladas métricas) de força vertical de aperto diretamente no carril. Esta imensa potência, gerada através de um eficiente mecanismo de alavanca, cria um bloqueio por fricção poderoso que é essencial para:

- Impedir a deslocação de grandes estruturas em condições de vento forte.

- Estacionamento seguro gruas de pórtico pesadas e gruas navio-terra (STS).

- Proporcionar uma travagem de emergência fiável quando integrado no sistema de controlo da grua.

Construído para toda a vida: Construção industrial para serviços pesados

Pesando 1110 kg, o YDGZ-40 é um testemunho da engenharia de serviço pesado. A sua carcaça robusta é concebida para resistir a vibrações extremas, cargas de impacto e atmosferas corrosivas comuns em ambientes marinhos e portuários. Os blocos de fricção são usinados com precisão a partir de aço avançado resistente ao desgaste, garantindo desempenho consistente e uma longa vida útil com manutenção mínima.

Concebido para estar sempre ativo: Instalação rápida e controlo manual

Compreendendo a necessidade de eficiência operacional, o YDGZ-40 foi concebido com caraterísticas que simplificam a integração e a manutenção:

- Interruptores de limite integrados: Fornecer sinais claros de "preso" e "libertado" ao PLC principal, evitando a ativação acidental do acionamento enquanto o travão está engatado e confirmando um estado seguro.

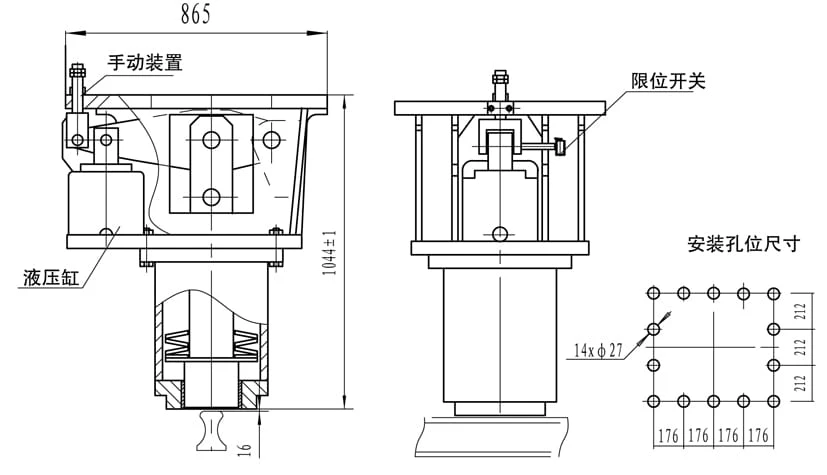

- Libertação manual cómoda: Equipado com um pega de desbloqueio manualCom o sistema de fixação de carris, este grampo de carril pode ser desengatado sem energia hidráulica. Esta caraterística é inestimável durante a instalação, colocação em funcionamento e manutenção de emergência, poupando tempo e recursos críticos.

Aplicações primárias

O YDGZ-40 é a escolha ideal para proporcionar proteção contra tempestades e segurança de estacionamento para uma vasta gama de equipamentos:

- Guindastes para portos e terminais (Ship-to-Shore, pórtico com pneus de borracha, pórtico montado em carris)

- Guindastes para estaleiros & Golias

- Pórticos industriais & Pontes rolantes

- Empilhadores-recuperadores & Equipamento de manuseamento de granéis

Especificações técnicas

| Parâmetro | Valor |

|---|---|

| Modelo | YDGZ-40 |

| Força de aperto nominal | 400 KN |

| Pressão hidráulica de funcionamento | 8 MPa |

| Curso do êmbolo | 16 mm |

| Peso | 1110 kg |

| Temperatura de funcionamento | 0°C a 40°C |

| Humidade relativa | ≤ 90% |

Proteja os seus activos hoje mesmo

Quando se trata de proteger o seu equipamento mais valioso, não há espaço para compromissos. O YDGZ-40 Grampo Hidráulico para Carril oferece a potência comprovada, a fiabilidade fail-safe e a construção durável que as suas operações exigem.

Quer esteja a especificar uma nova grua ou à procura de uma substituição fiável para um travão de carril existente, a nossa equipa está pronta para ajudar. Contacte-nos hoje para um orçamento detalhado, consulta técnica ou para discutir como selecionar o grampo de carril certo para a sua aplicação em locais de vento forte.