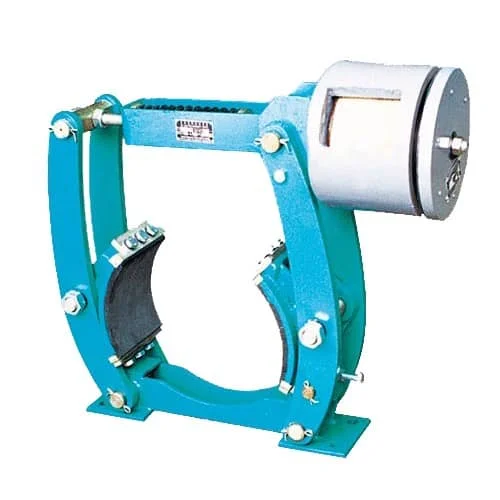

The ZWZ3 series DC electromagnetic drum brakes are engineered for high-performance industrial applications including mining, metallurgy, port handling, construction machinery, and transportation systems. Designed to meet strict industry standards (GB6334-86, JB/T7685-2006), these brakes deliver reliable stopping power, long service life, and operational safety in demanding environments.

Key Features & Advantages

- High Torque Range: From 35 Nm to 7100 Nm, suitable for various load requirements.

- Standard Compliance: Conforms to GB6334-86 and JB/T7685-2006, ensuring quality and safety.

- Versatile Models: Available in diameters from 160mm to 800mm, with options for parallel and serial coil configurations.

- Robust Construction: Designed for temperatures from -25°C to -40°C, with corrosion-resistant materials for harsh environments.

- Flexible Power Supply: Compatible with DC220V and DC110V, with custom voltage options available.

- Long Continuous Operation: Capable of sustained engagement with up to 50% duty cycle, reducing downtime.

- Environmental Suitability: Suitable for indoor use or outdoor installations protected from rain and snow, with altitude limits up to 2000m.

Technical Explanation of ZWZ3 Series Brake Model Naming Conventions

The ZWZ3 series electromagnetic drum brakes are available in two main configurations: Type-1 (Parallel Coil) and Type-2 (Parallel + Series Coil). Each configuration has a specific naming convention that encodes key technical parameters, enabling precise identification and selection for various industrial applications.

1. Type-1 (Parallel Coil) Model Naming

Format:

ZWZ3 – [A]/[B]

| Element | Description | Example |

|---|---|---|

| ZWZ3 | Series designation | — |

| [A] | Brake wheel diameter in millimeters | 160, 200, 250, 315, 400, 630, 800 |

| [B] | Electromagnet model number (specifies coil size and magnetic force) | 100, 200, 300, 500, 630, 710, 800 |

Example:

- ZWZ3-160/100:

- Brake wheel diameter: 160 mm

- Electromagnet model: 100

| Model | Torque (N.m) | A | b | C | d | D | E | F | G | H | h1 | i | K | M | m | n | Brake shoe back distance(Max.) | s | weight(kg) | |

| Parallel coils | ||||||||||||||||||||

| Power-on duration | S(Max.) | |||||||||||||||||||

| 25% | 40% | |||||||||||||||||||

| ZWZ3-160/100 | 35.5 | 28 | 259 | 65 | 80 | 14 | 160 | 150 | 90 | 150 | 396 | 132 | 55 | 130 | 185 | 118 | 6 | 0.6 | 2 | 13 |

| 3 | ||||||||||||||||||||

| ZWZ3-160/200 | 140 | 112 | 306 | 421 | 168 | 0.7 | 2.5 | 22 | ||||||||||||

| 4 | ||||||||||||||||||||

| ZWZ3-200/100 | 40 | 31.5 | 299 | 80 | 80 | 14 | 200 | 180 | 90 | 165 | 444 | 160 | 55 | 145 | 185 | 118 | 8 | 0.6 | 2 | 26 |

| 3 | ||||||||||||||||||||

| ZWZ3-200/200 | 160 | 125 | 346 | 469 | 168 | 0.7 | 2.5 | 35 | ||||||||||||

| 4 | ||||||||||||||||||||

| ZWZ3-200/300 | 315 | 280 | 390 | 495 | 220 | 0.8 | 3 | 52 | ||||||||||||

| 4.5 | ||||||||||||||||||||

| ZWZ3-250/200 | 200 | 160 | 350 | 100 | 95 | 18 | 250 | 198 | 100 | 200 | 534 | 190 | 65 | 180 | 250 | 168 | 10 | 0.8 | 2.5 | 56 |

| 4 | ||||||||||||||||||||

| ZWZ3-250/300 | 450 | 355 | 380 | 550 | 220 | 0.9 | 3 | 60 | ||||||||||||

| 4.5 | ||||||||||||||||||||

| ZWZ3-315/200 | 250 | 200 | 376 | 125 | 120 | 18 | 315 | 250 | 120 | 245 | 604 | 225 | 80 | 220 | 298 | 168 | 10 | 0.8 | 2.5 | 70 |

| 4 | ||||||||||||||||||||

| ZWZa-315/300 | 500 | 450 | 426 | 630 | 220 | 0.9 | 3 | 85 | ||||||||||||

| 4.5 | ||||||||||||||||||||

2. Type-2 (Parallel + Series Coil) Model Naming

Format:

ZWZ3 – [A]/[B][C]-[D]

| Element | Description | Example |

|---|---|---|

| ZWZ3 | Series designation | — |

| [A] | Brake wheel diameter in millimeters | 400, 630, 800 |

| [B] | Electromagnet model number | 500, 600, 700, 800 |

| [C] | Coil configuration code | I (parallel), II-VII (series configurations) |

| [D] | Additional specifications or customer requirements | e.g., “Custom” or specific remarks |

Example:

- ZWZ3-400/500I:

- Brake wheel diameter: 400 mm

- Electromagnet model: 500

- Coil configuration: Parallel (I)

- ZWZ3-630/500II:

- Brake wheel diameter: 630 mm

- Electromagnet model: 500

- Coil configuration: Series (II)

| Model | Rated Force (kN) | Brake Diameter (mm) | Friction Material | Rated Voltage (V) | Brake Time (s) | Operating Temperature Range (°C) | Protection Level | Weight (kg) | Connection Type | Application Environment | Notes |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ZWZs-400/400 | 20 | 400 | Ceramic Composite | 220 | 0.3 | -20 to 80 | IP65 | 25 | Flange | Heavy Industry | Standard Model |

| ZWZ3-400/500I | 25 | 400 | Metal Friction | 220 | 0.25 | -20 to 80 | IP65 | 28 | Threaded | Lifting Equipment | High-Performance Model |

| ZWZs-500/400 | 30 | 500 | Ceramic Composite | 220 | 0.4 | -20 to 80 | IP67 | 30 | Flange | Conveyor Systems | Heavy Load |

| ZWZs-500/500 | 35 | 500 | Ceramic Composite | 220 | 0.35 | -20 to 80 | IP65 | 32 | Flange | Heavy Industry | Common Model |

| ZWZs-500/600 | 40 | 500 | Ceramic Composite | 220 | 0.4 | -20 to 80 | IP65 | 35 | Flange | Heavy Industry | High Power |

| ZWZ3-630/500 | 45 | 630 | Metal Friction | 220 | 0.3 | -20 to 80 | IP67 | 40 | Threaded | Lifting Machinery | High Performance |

| ZWZs-630/600 | 50 | 630 | Ceramic Composite | 220 | 0.35 | -20 to 80 | IP65 | 45 | Flange | Conveyor Systems | Large Load |

| ZWZs-630/700 | 55 | 630 | Ceramic Composite | 220 | 0.4 | -20 to 80 | IP65 | 50 | Flange | Heavy Industry | High Requirements |

| ZWZs-710/600 | 60 | 710 | Ceramic Composite | 220 | 0.4 | -20 to 80 | IP65 | 55 | Flange | Heavy Industry | High Performance |

| ZWZs-710/700 | 65 | 710 | Ceramic Composite | 220 | 0.45 | -20 to 80 | IP65 | 60 | Flange | Heavy Industry | Heavy Load |

| ZWZs-710/800 | 70 | 710 | Ceramic Composite | 220 | 0.5 | -20 to 80 | IP65 | 65 | Flange | Large Machinery | High Performance |

| ZWZ3-800/700 | 75 | 800 | Metal Friction | 220 | 0.3 | -20 to 80 | IP67 | 70 | Threaded | Lifting Equipment | High Performance |

| ZWZ3-800/800 | 80 | 800 | Metal Friction | 220 | 0.35 | -20 to 80 | IP67 | 75 | Threaded | Heavy Industry | Heavy Load |

Notes:

- Brake Diameter: Diameter of the brake disc or friction surface.

- Rated Force: Max braking force under rated voltage and conditions.

- Friction Material: Ceramic composite or metal friction pads, affecting wear resistance and braking performance.

- Connection Type: Flange, threaded, or quick-connect, customized per equipment needs.

- Application Environment: Suitable for heavy industry, lifting machinery, conveyor systems, etc.

Comparison Summary

| Feature | Type-1 (Parallel Coil) | Type-2 (Parallel + Series Coils) |

|---|---|---|

| Configuration | Single coil, parallel connection | Multiple coils, parallel or series connection |

| Model Naming | Diameter / Electromagnet Model | Diameter / Electromagnet Model + Coil Type Code (I or II-VII) |

| Application Suitability | Standard industrial braking | Complex control requirements, adjustable braking force |

| Control Complexity | Simple, easy to maintain | More complex, adaptable to varied electrical control schemes |

Visual Diagram Description

TEXT+---------------------------------------------------------+

| Model Naming Structure |

+---------------------------------------------------------+

| |

| [Series Prefix] - [Wheel Diameter] / [Electromagnet Model] |

| |

| Example: ZWZ3-160/100 |

| |

| For Type-2: |

| ZWZ3 - [Diameter] / [Electromagnet Model][Coil Type]-[Remarks] |

| |

| Example: ZWZ3-400/500I |

| |

+---------------------------------------------------------+

Summary

- Type-1 (ZWZ3 – [A]/[B]): Suitable for straightforward, high-force braking needs with a single, parallel-connected coil.

- Type-2 (ZWZ3 – [A]/[B][C]-[D]): Offers enhanced control flexibility with multiple coil configurations, ideal for complex or high-demand applications.

This structured naming system allows engineers and technicians to quickly identify the specific model’s configuration, ensuring precise matching to application requirements.