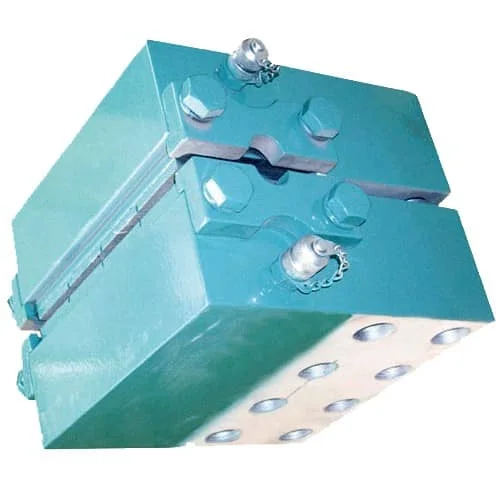

At our company, we’re proud of the robust and reliable performance of our ADH Series Hydraulic Direct-Acting Brakes. These brakes—including the popular ADH60, ADH90, and ADH120 models—are the workhorses for service braking applications on equipment like winches, tensioning devices, and smaller conveyors.

We understand that proper installation and maintenance are key to getting the most out of your investment. Based on conversations with our valued customers, our engineering team has compiled answers to the most frequently asked questions about the ADH Series.

Let’s dive in.

1. What is a “Direct-Acting” brake and when should I use it?

“Direct-acting” means the hydraulic pressure is applied directly to the brake piston to generate the clamping force. This is different from a “spring-applied” or “fail-safe” brake, which uses hydraulic pressure to release a pre-applied spring force.

When to use an ADH Series Direct-Acting Brake: You should use this type of brake for service braking or dynamic tensioning applications. This means its primary job is to actively and controllably slow down a moving load, like modulating the speed of a winch unwinding. It is not designed to be a fail-safe parking or emergency brake. For applications that require the brake to engage automatically during a power loss (like a hoist), you should select a spring-applied, hydraulic-release brake, such as our SH Series.

2. How do I properly install and align the ADH caliper?

Proper alignment is the single most important factor for ensuring even pad wear and optimal performance.

Step-by-Step Guide:

- Center the Caliper: Mount the ADH caliper loosely over the brake disc. Use shims under the mounting bracket as needed to ensure the caliper is perfectly centered, with equal space on both sides of the disc.

- Ensure Parallelism: The mounting face of the caliper must be parallel to the face of the brake disc. Use a straight edge or feeler gauges to check this. Misalignment here will cause tapered pad wear.

- Check Radial Position: The brake pads should make full contact with the friction surface of the disc. They should not overhang the outer edge or touch the inner hub/mounting bolts of the disc.

- Torque Mounting Bolts: Once alignment is perfect, tighten the mounting bolts to the recommended torque specifications found in your product manual.

3. What type of hydraulic fluid should I use for my ADH brake?

For optimal performance and seal longevity, we recommend using a standard ISO VG 32 or VG 46 anti-wear mineral-based hydraulic oil.

Important Considerations:

- Viscosity: In very cold environments, a lower viscosity fluid (VG 32) is preferable. In very hot environments, a higher viscosity (VG 46) may be better.

- Compatibility: Do not use automotive brake fluid (DOT 3, 4, 5). These glycol-based fluids are incompatible with the standard seals used in our ADH brakes and will cause them to swell and fail. If your application requires a special fluid, please consult our engineering team for compatible seal options.

- Cleanliness: Always use new, clean fluid from a sealed container. Contaminated fluid is the number one cause of premature seal failure.

4. How can I tell when it’s time to replace the brake pads?

The ADH Series is equipped with a simple manual wear adjustment mechanism. You can visually inspect the brake pads.

Rule of Thumb: The brake pads should be replaced when the friction material thickness reaches a minimum of 2-3mm (approx. 1/8 inch). Allowing the pads to wear down further risks damaging the brake disc as the metal backing plate could make contact.

Our brakes are designed for quick and easy pad replacement. We strongly recommend using our genuine replacement pads to guarantee the correct friction coefficient and performance characteristics.

5. My brake seems to be “dragging” or not fully releasing. What’s the cause?

Brake drag is a common issue that can almost always be traced back to the hydraulic system. The ADH brake itself is a simple device; if it’s not releasing, it’s because hydraulic pressure is not being fully relieved.

Common Causes:

- Residual Pressure: The most frequent cause. Ensure your hydraulic control valve provides a direct, un-obstructed path for the fluid to return to the tank. Some systems can trap a small amount of pressure, which is enough to cause light pad contact.

- Sticky Control Valve: A directional control valve that is worn or contaminated may not fully shift to the “open” position, trapping fluid in the brake line.

- Collapsed Hydraulic Hose: An internally damaged hose can act like a one-way valve, allowing fluid in but restricting its return.

- Improper Piston Retraction: While less common, severe contamination within the caliper can cause the piston to become sticky. This usually indicates a need for a full reseal and cleaning.

Have More Questions? We’re Here to Help.

We hope this guide has answered your immediate questions about the ADH Series hydraulic brakes. Our goal is to ensure you get the safe, reliable, and long-lasting performance our products are designed to deliver.

If you have a question that wasn’t covered here or need technical support for a specific application, don’t hesitate to reach out to our team.

Contact our technical support team today for expert assistance.